Wig drying device

A drying device and wig technology, applied in wigs, heating devices, drying solid materials, etc., can solve the problems of low drying efficiency and high labor intensity, and achieve the effects of prolonging drying time, reducing labor intensity, and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

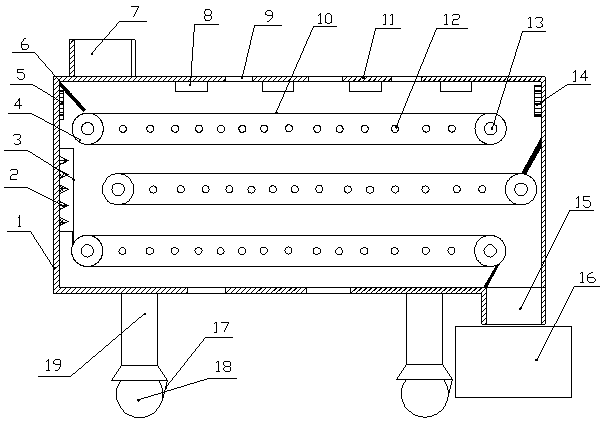

[0017] Such as figure 1 As shown, a wig drying device includes a box body 1, the box body 1 is a cuboid structure, the lower end of the box body 1 is fixedly connected with a leg 19, and the lower end of the leg 19 is rotatably connected There are rollers 18, and a belt conveying mechanism is arranged in the horizontal direction in the box body 1. There are three belt conveying mechanisms, and the conveying directions of two adjacent belt conveying mechanisms are opposite. The discharge end of the belt conveyor mechanism is located directly above the feed end of the belt conveyor mechanism on the lower floor adjacent to it. The belt conveyor mechanism includes a driving roller 4 and a driven roller 13, and the outside of the box body 1 A drive motor connected to the driving roller 4 is provided, and the driving roller 4 and the driven roller 13 are connected through a ring-shaped high-temperature-resistant mesh belt 10. The upper and lower half widths of the high-temperature-r...

Embodiment 2

[0020] Such as figure 1As shown, a wig drying device includes a box body 1, the box body 1 is a cuboid structure, the lower end of the box body 1 is fixedly connected with a leg 19, and the lower end of the leg 19 is rotatably connected There are rollers 18, and a belt conveying mechanism is arranged in the horizontal direction in the box body 1. There are three belt conveying mechanisms, and the conveying directions of two adjacent belt conveying mechanisms are opposite. The discharge end of the belt conveyor mechanism is located directly above the feed end of the belt conveyor mechanism on the lower floor adjacent to it. The belt conveyor mechanism includes a driving roller 4 and a driven roller 13, and the outside of the box body 1 A drive motor connected to the driving roller 4 is provided, and the driving roller 4 and the driven roller 13 are connected through a ring-shaped high-temperature-resistant mesh belt 10. The upper and lower half widths of the high-temperature-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com