Method for detecting position degree of porous system

A detection method and position degree technology, applied in the field of measurement, can solve the problems of heavy detection workload and difficulty in hole position degree detection, and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The following takes an engine casing part as an example to describe in detail a method for detecting the position degree of a porous system provided by the present invention.

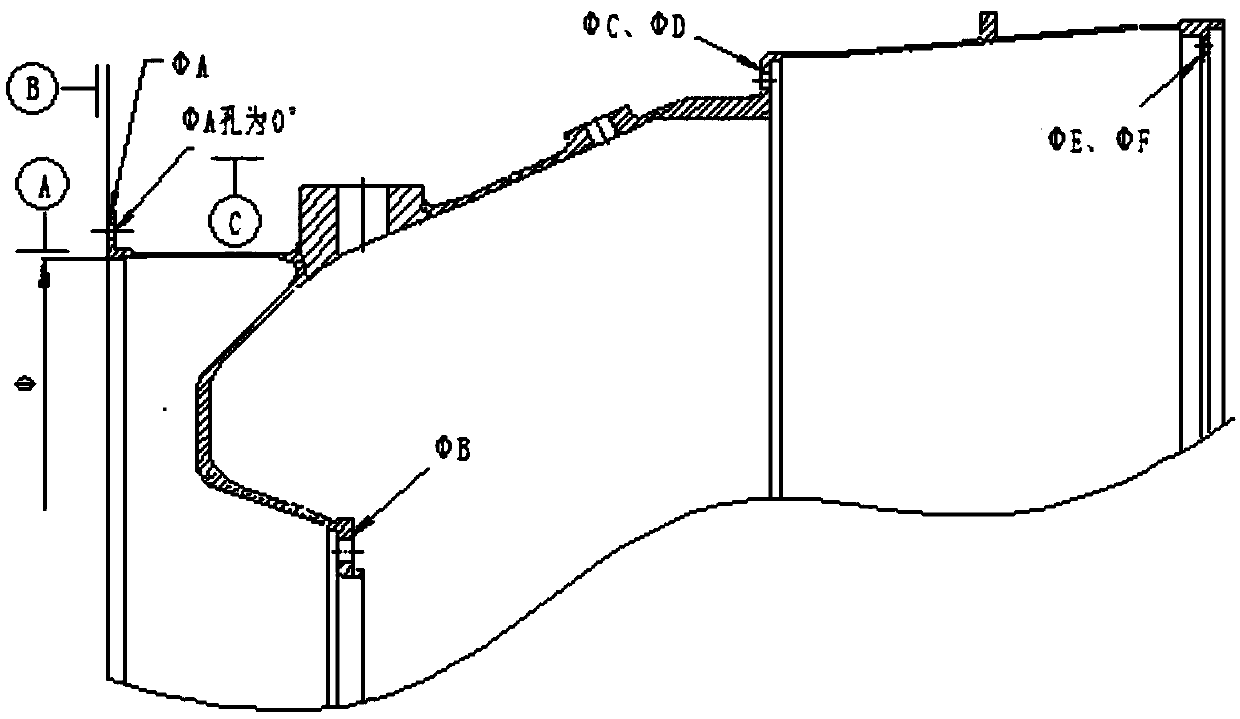

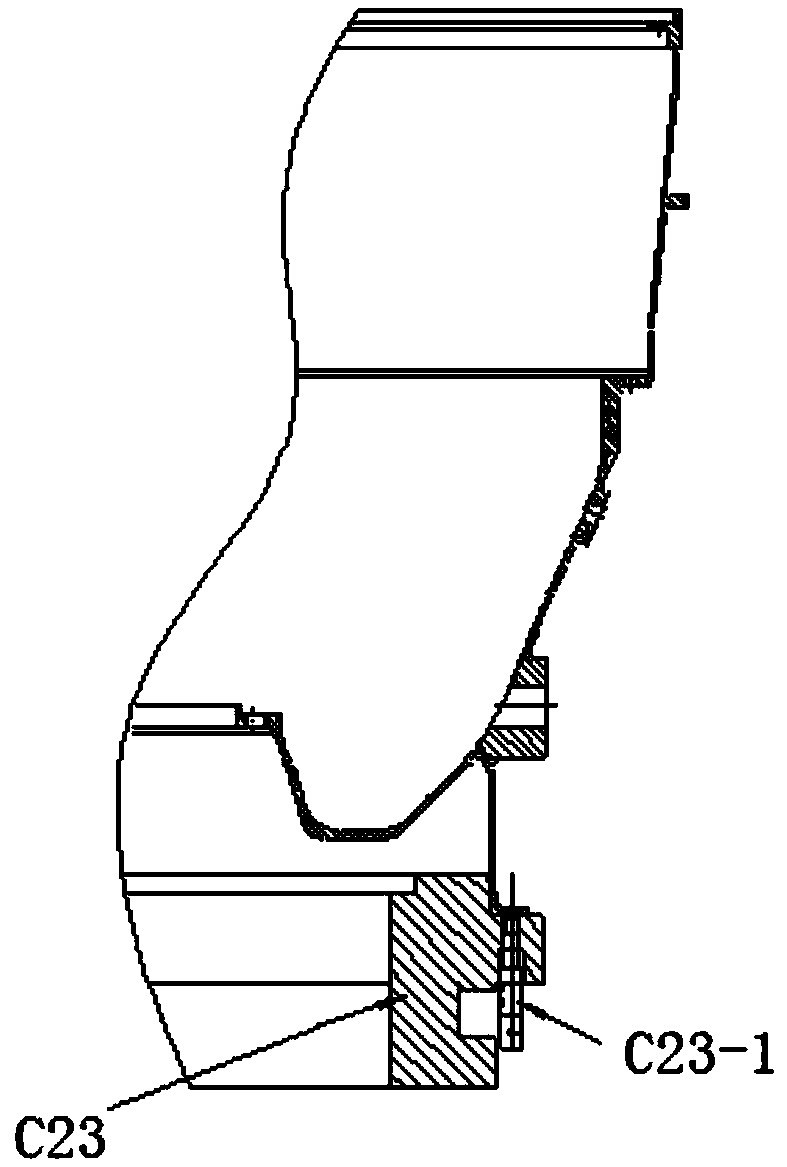

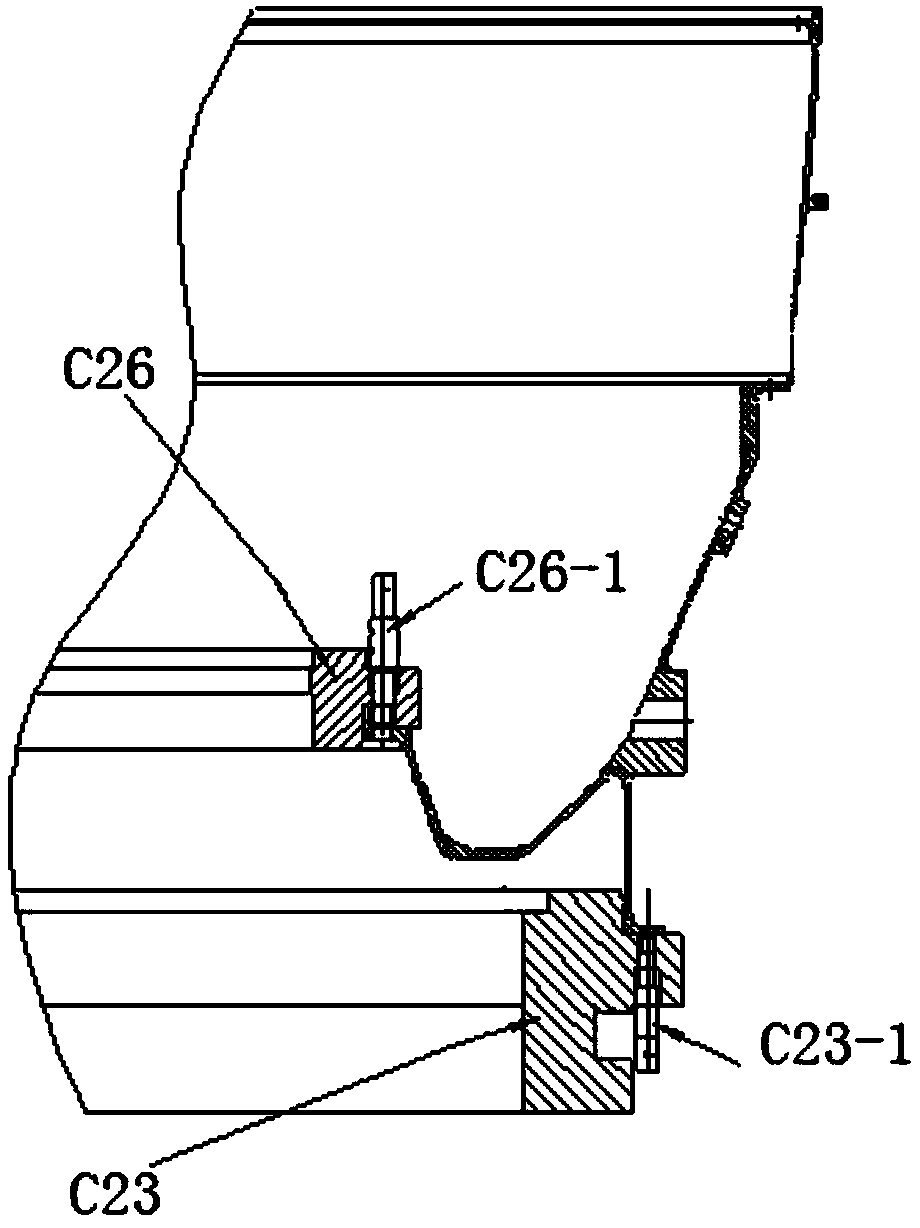

[0046] like figure 1 As shown in the figure, the receiver part includes a first sub receiver, a second sub receiver and a third sub receiver from left to right. The three sub receivers are formed by welding end to end. A coaxial circular spigot is provided, and the spigots of the three sub receivers are coaxial, and the circular spigots of two adjacent receivers are connected. After the three sub-cassettes are welded and formed, four spigots are formed from left to right, and each spigot is a mounting surface, which is a first mounting surface, a second mounting surface, a third mounting surface and a fourth mounting surface.

[0047] Since the sub-casing will be deformed after welding, each mounting surface needs to be turned and finished after welding. During processing, the end of the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com