Monotonic tensile parameter-based metal material fatigue crack growth model construction method

A fatigue crack propagation, metal material technology, applied in the field of metal material fatigue crack propagation model construction based on monotonic tensile parameters, can solve the problems of deviation from the true value, consuming a lot of manpower and material resources, unable to meet engineering applications, etc., to achieve crack propagation. The effect of accurate prediction of rate, avoidance of test cost, and avoidance of the effect of crack growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

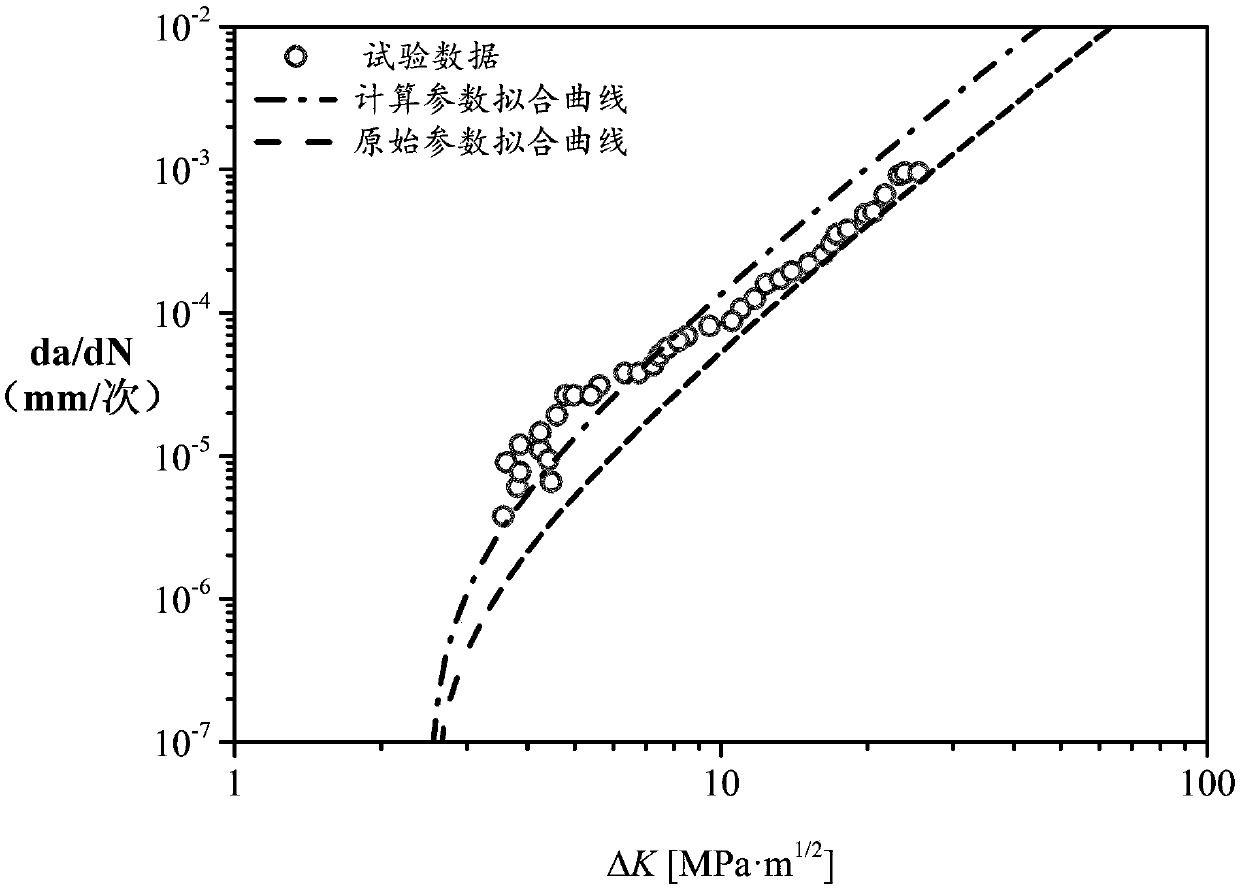

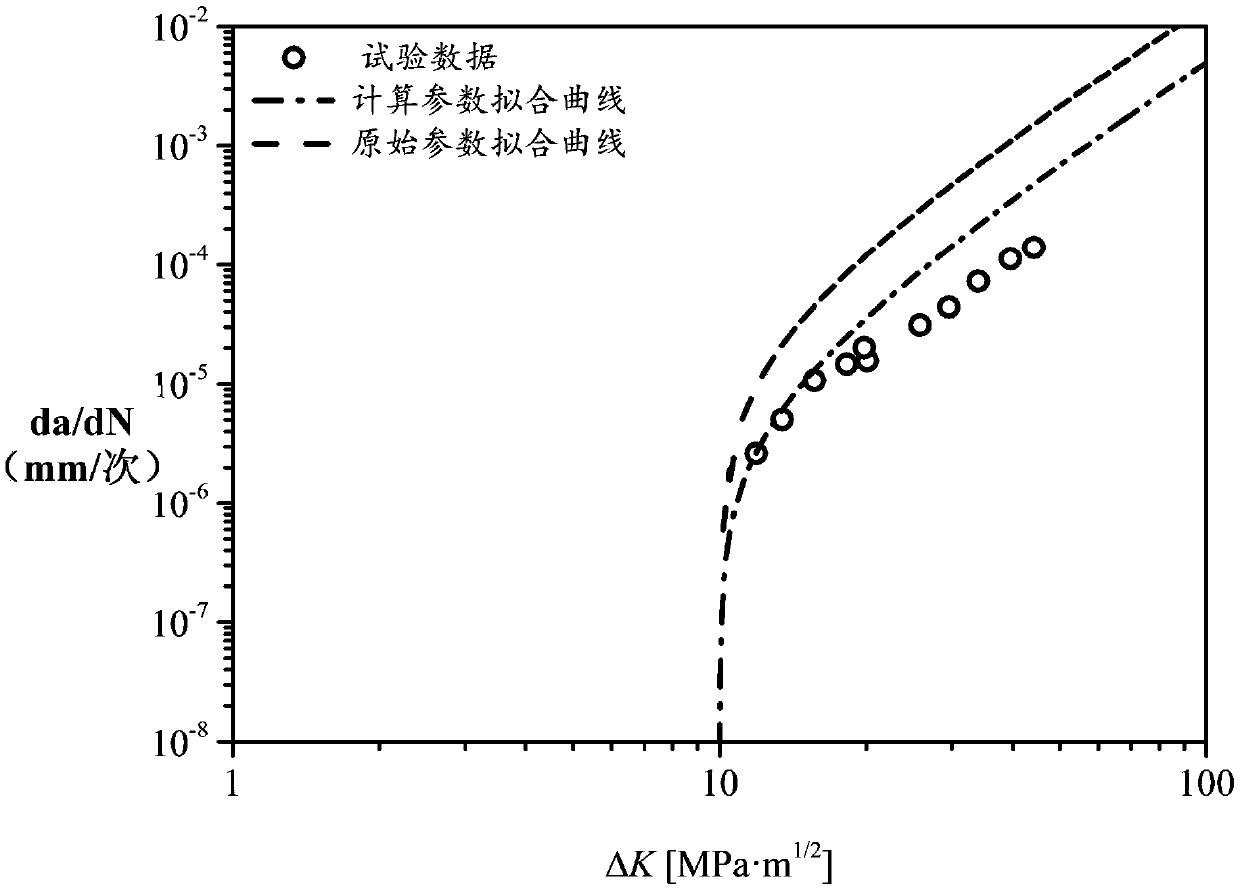

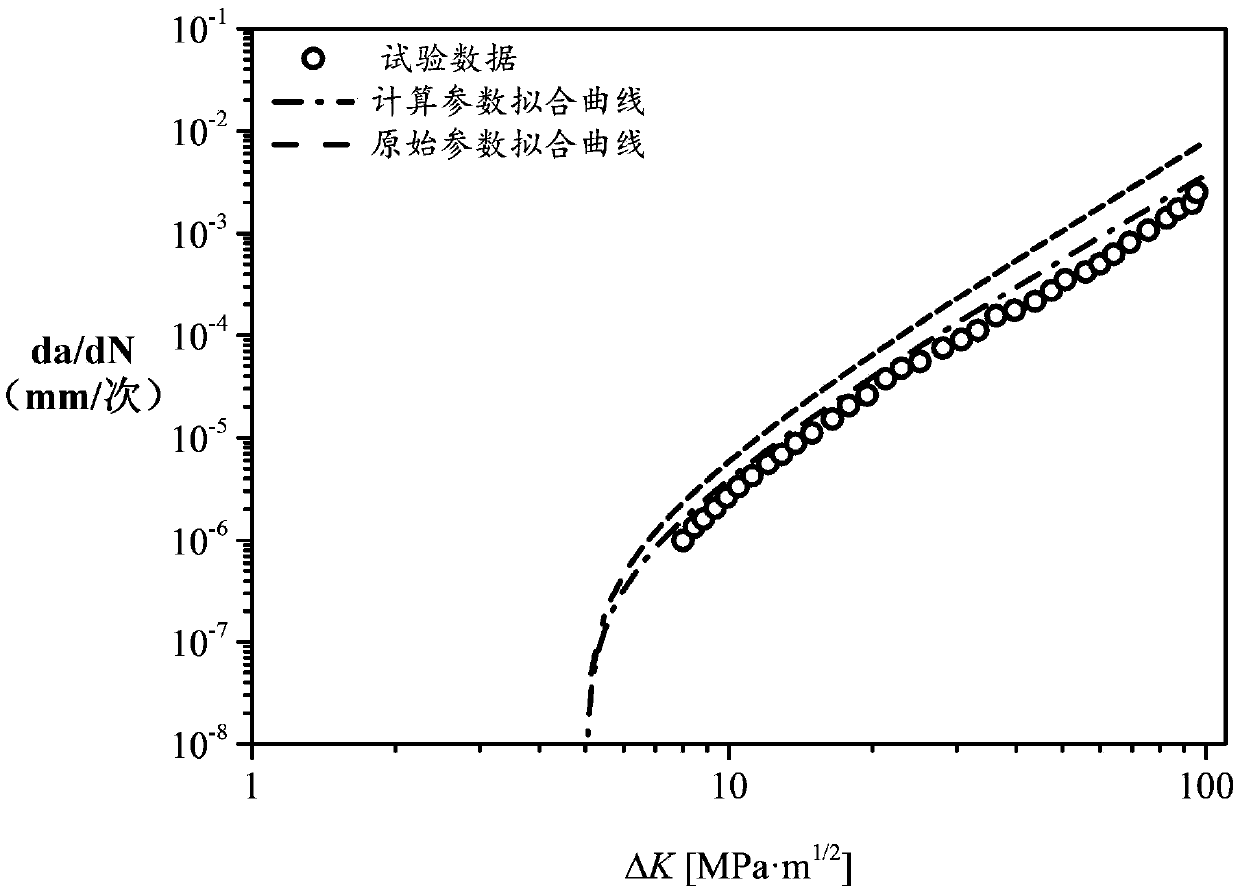

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0043] A method for constructing a metal material fatigue crack growth model based on monotone tensile parameters, comprising the following steps:

[0044] Step 1: Obtain a crack growth rate model based on linear cumulative damage:

[0045]

[0046] In the formula: a is the crack length, N is the number of cycles, da / dN is the crack growth rate, U is the crack closure parameter, σ yc is the cyclic yield stress, c is the fatigue ductility exponent, n′ is the cyclic strain hardening exponent, ε f ' is the fatigue ductility index, E is the modulus of elasticity, ΔK is the range of stress intensity factor, ΔK th is the threshold value of the stress intensity factor range;

[0047] Step 2: The closure parameter U is characterized by the stress ratio R as follows:

[0048] U=0.4854+0.3536R+0.1686R 2 (2)

[0049] Step 2: Characterization of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com