Full tensor magnetic gradient measurement assembly calibration system and calibration method

A technology for measuring components and calibration systems, which is applied in the measurement of magnetic variables, measuring devices, instruments, etc., can solve the problems of inability to provide calibration systems and calibration methods, and achieve the effect of easy implementation, guaranteeing measurement accuracy, and simple and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

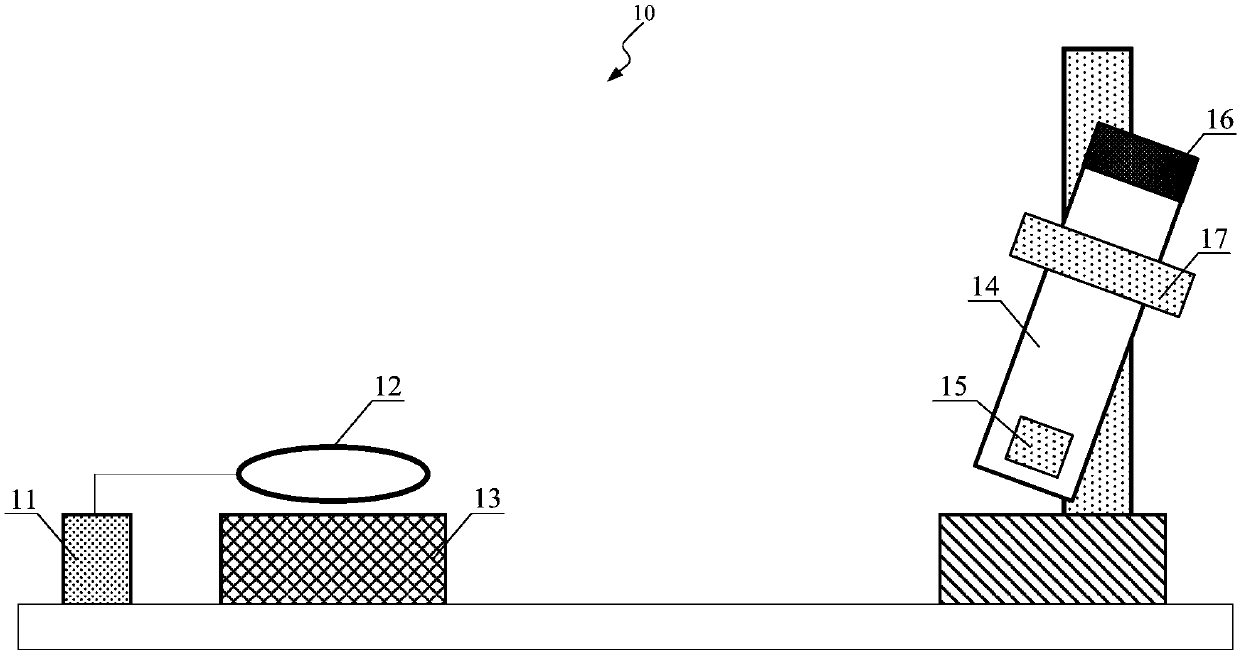

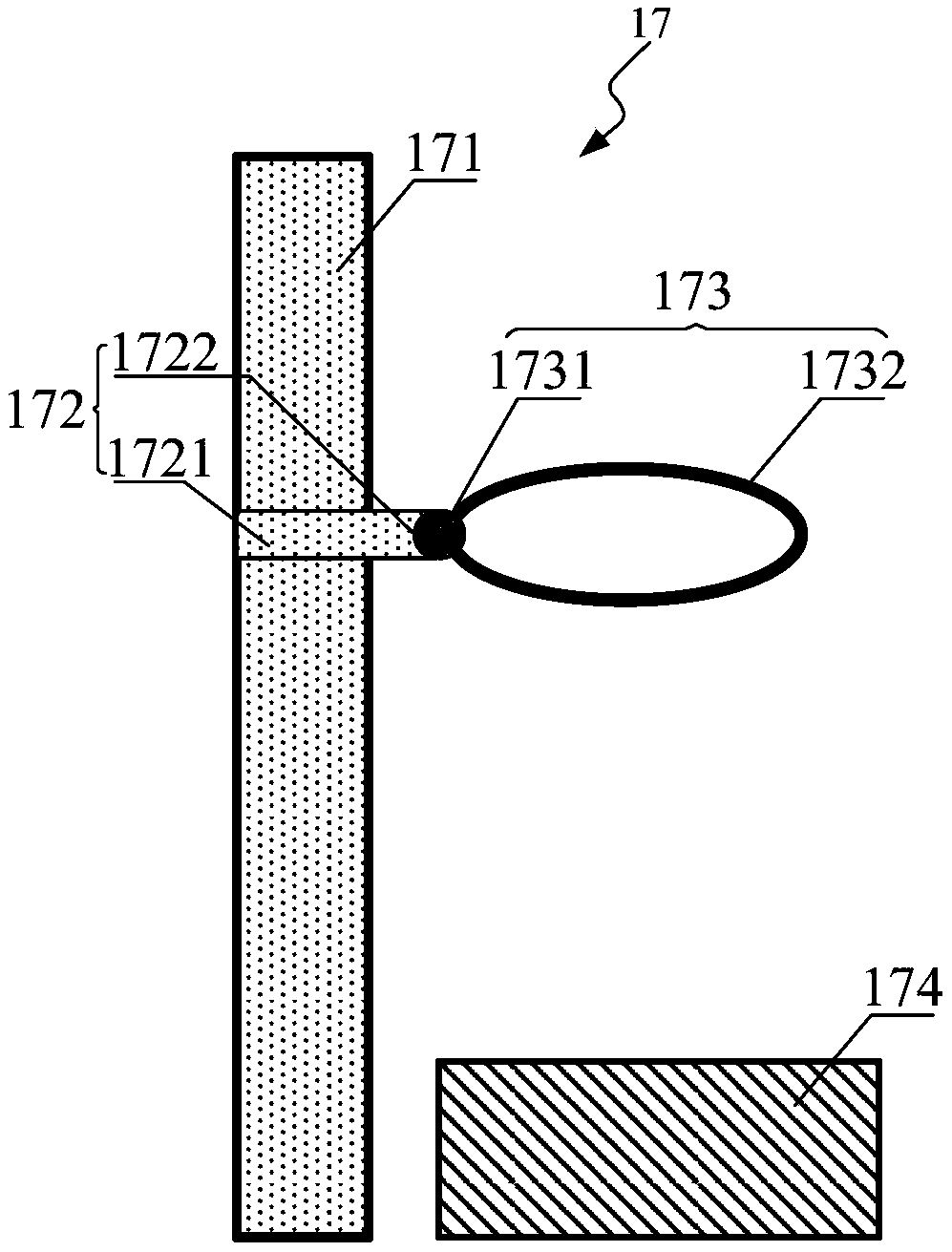

[0063] Such as figure 1 As shown, this embodiment provides a full tensor magnetic gradient measurement component calibration system 10, and the calibration system 10 includes:

[0064] An excitation source 11, configured to provide an excitation signal;

[0065] A calibration source 12, electrically connected to the excitation source 11, for generating a calibration magnetic field driven by the excitation source 11;

[0066] The non-magnetic turntable 13 is arranged under the calibration source 12 and is used to adjust the angle of the calibration source 12;

[0067] The mounting bracket 14 is arranged on one side of the calibration source 12 for providing a mounting platform;

[0068] A full tensor magnetic gradient measurement component 15 is arranged on the mounting bracket 14 for measuring the magnetic field gradient value generated by the calibration source 12 at the full tensor magnetic gradient measurement component 15;

[0069] The measurement and control component ...

Embodiment 2

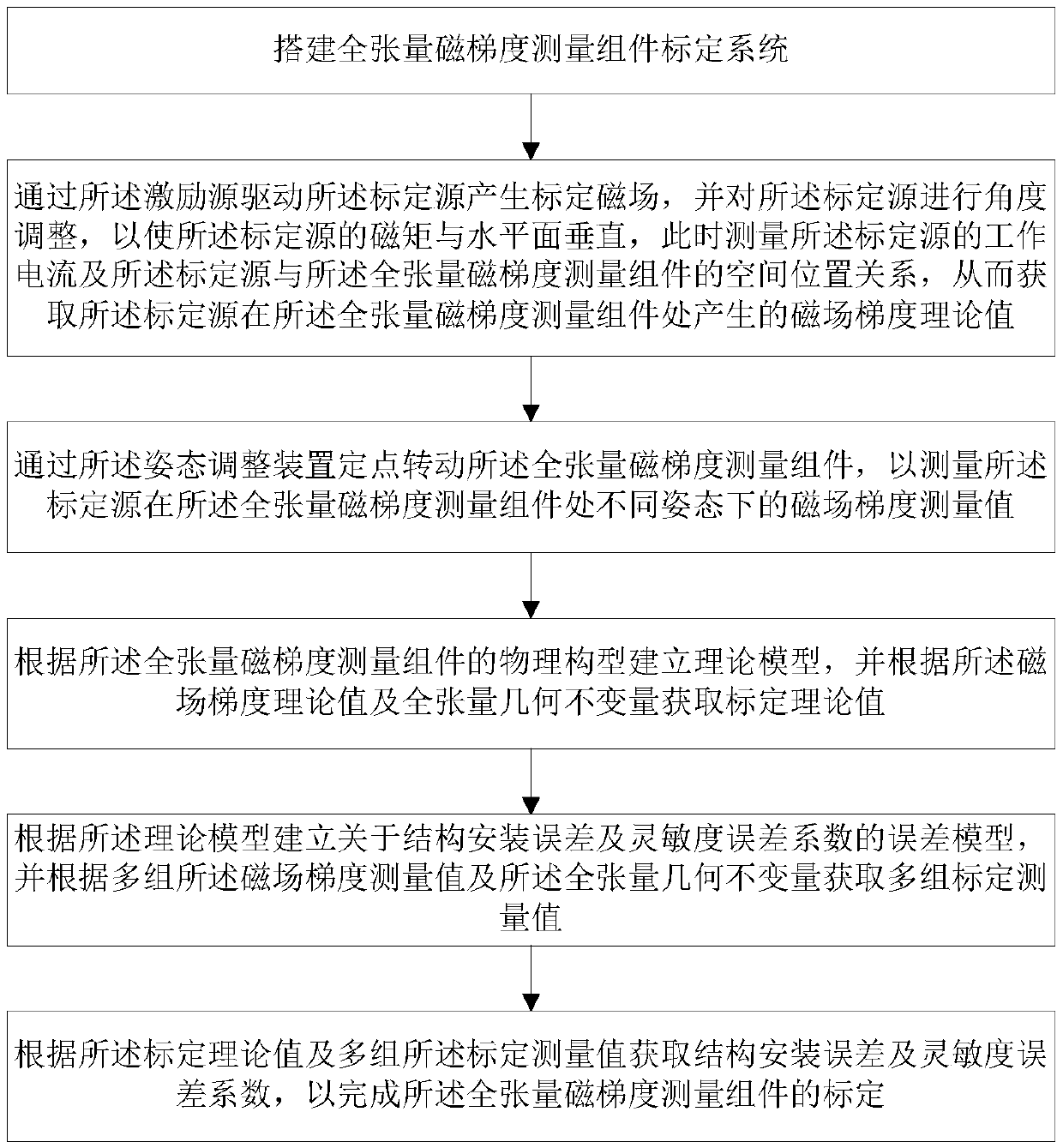

[0089] Such as image 3 As shown, this embodiment provides a calibration method for a full tensor magnetic gradient measurement component, the calibration method comprising:

[0090] Set up the full tensor magnetic gradient measurement component calibration system as described in Embodiment 1;

[0091] The calibration source is driven by the excitation source to generate a calibration magnetic field, and the angle of the calibration source is adjusted so that the magnetic moment of the calibration source is perpendicular to the horizontal plane. At this time, the operating current of the calibration source and the calibration source are measured. Calibrate the spatial position relationship between the source and the full tensor magnetic gradient measurement component, so as to obtain the theoretical value of the magnetic field gradient generated by the calibration source at the full tensor magnetic gradient measurement component;

[0092] Rotate the full tensor magnetic gradi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Magnetic moment | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com