Remote pressure plate inspection system

A technology of inspection system and pressure plate, which is applied in the field of power system, can solve the problems that the camera cannot capture the state of the pressure plate and the camera must move, so as to avoid uncontrollable factors, reduce the workload of personnel, improve work efficiency and inspection quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the following description is only for explaining the present invention and not limiting its content.

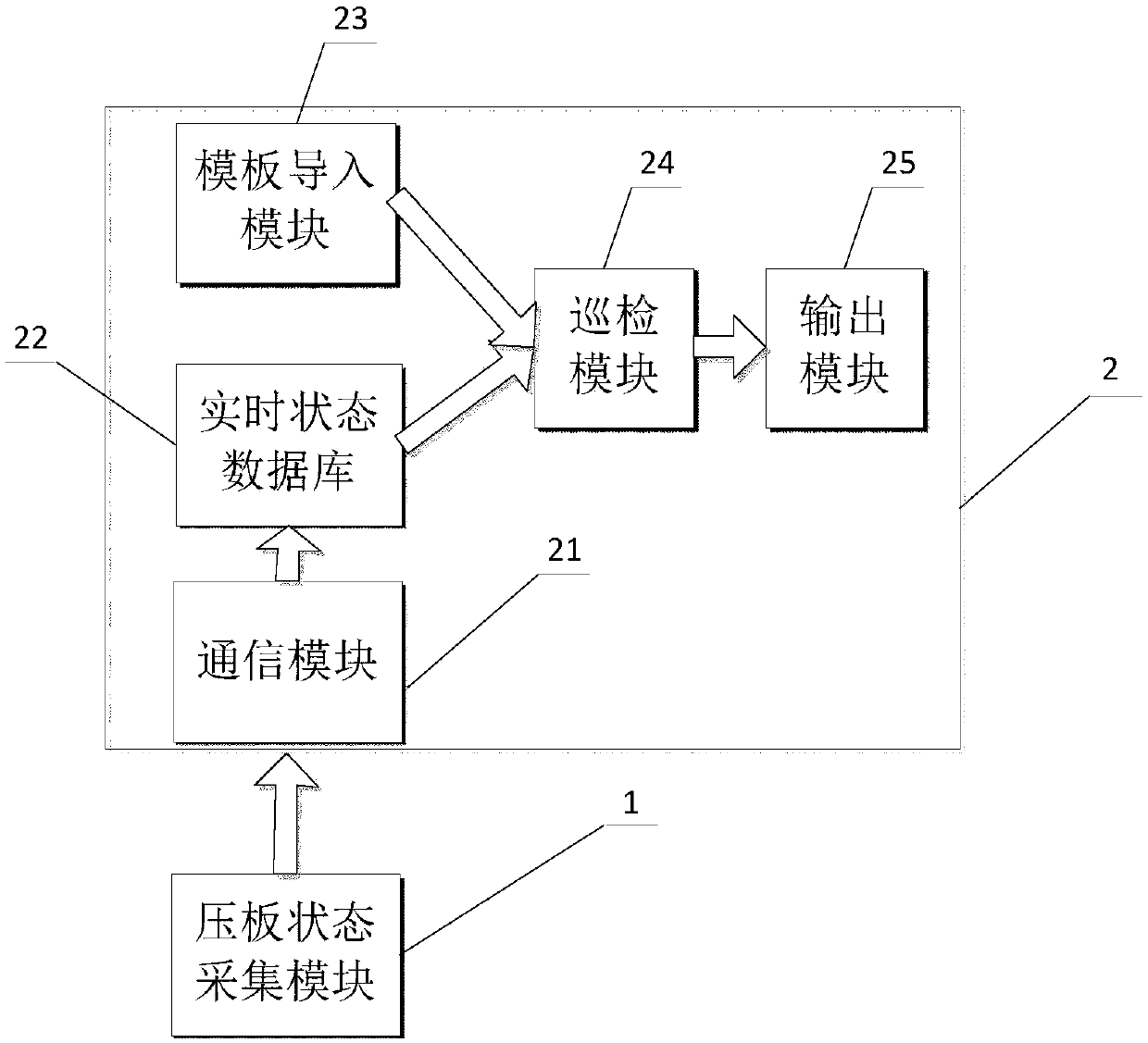

[0023] Such as figure 1 As shown, a remote platen inspection system is characterized in that it includes a platen state acquisition module 1 and inspection software 2; the platen state acquisition module 1 realizes the acquisition of the platen throwing and withdrawing state;

[0024] The inspection software 2 includes a communication module 21, a real-time status database 22, a template import module 23, an inspection module 24 and an output module 25;

[0025] The communication module 21 communicates with the platen state acquisition module 1, and stores the real-time state of the platen in the real-time state database 22;

[0026] Described template import module 23 is the import interface of platen inspection template, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com