An integral fixed seat structure

A fixed seat, the overall technology, applied in the direction of electromechanical devices, electrical components, control mechanical energy, etc., can solve the problems of inconvenient installation and disassembly of the fixed seat, poor fixing effect, deformation damage, etc., to improve convenience and facilitate installation and disassembly , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

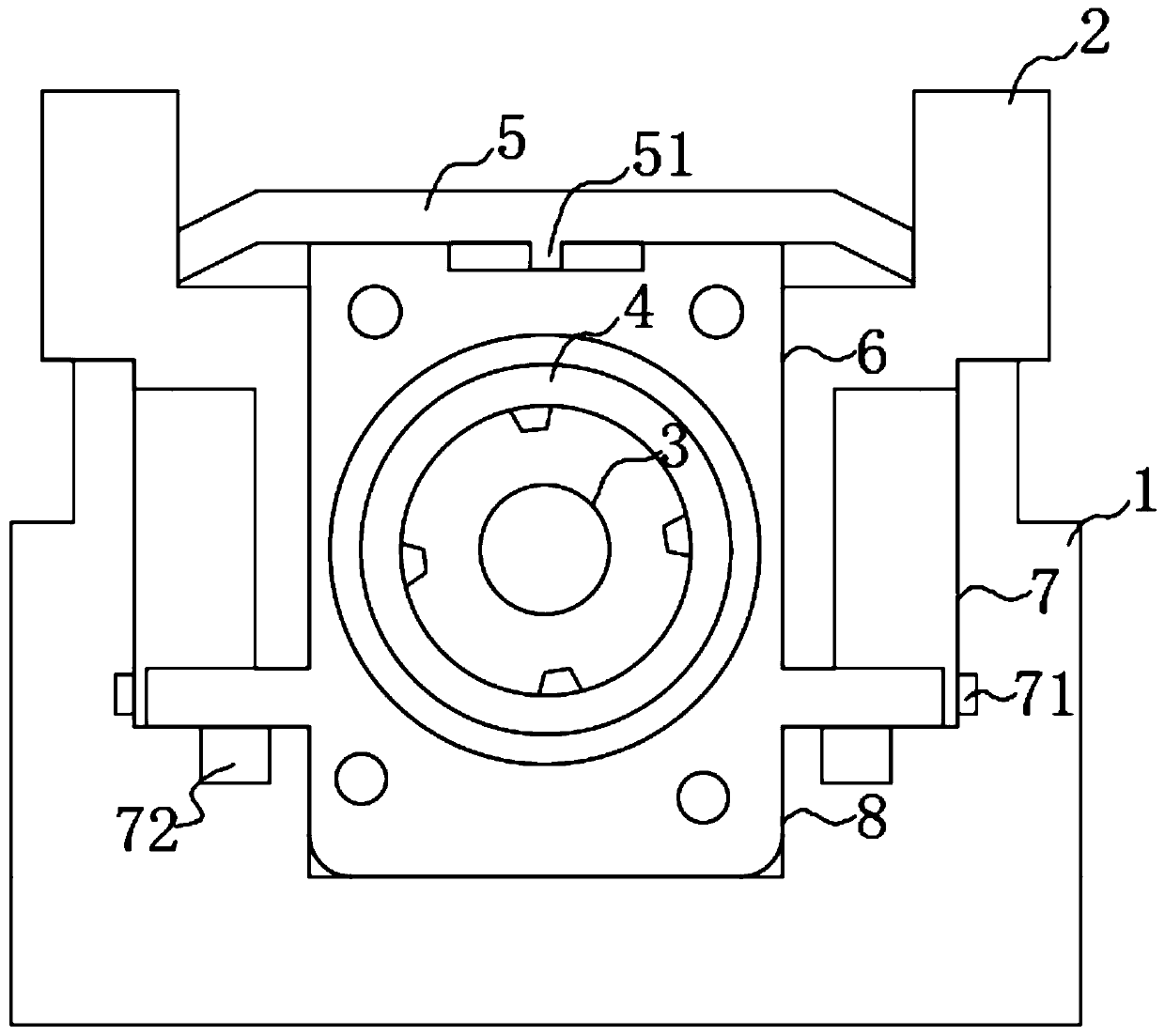

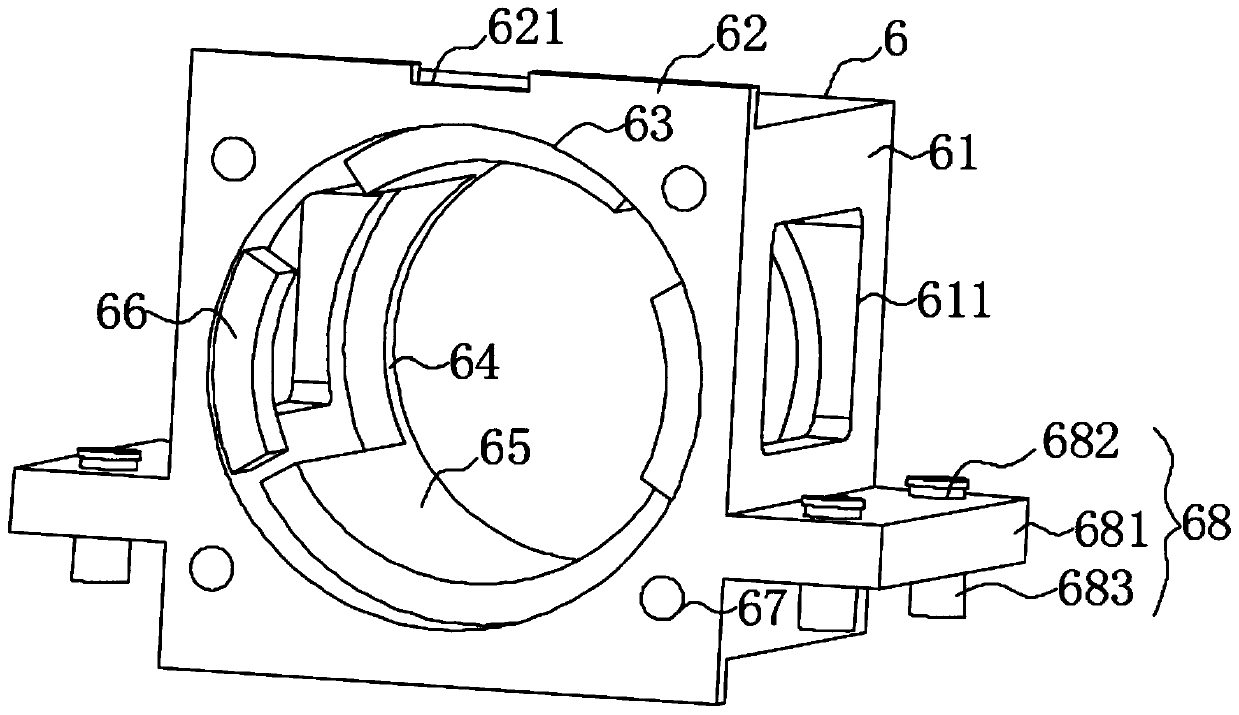

[0018] see Figure 1-2 , the present invention provides a technical solution: an integral fixed seat structure, including a base 1, an upper chute 7 is opened in the middle of the upper end surface of the base 1, and the left and right side walls of the lower part of the inner cavity of the upper chute 7 are both There is a first slide rail 71, and a second slide rail 72 is provided on the left and right sides of the bottom end surface of the upper chute 7, and the inner end of the second slide rail 72 is provided with several threaded holes for connecting bolts 683, The middle part of the bottom end of the upper chute 7 is provided with a chute 8, the bottom of the mounting plate 62 will be engaged in the inner cavity of the chute 8, and the installation wings 68 will be placed on the bottom surface of the inner cavity of the upper chute 7, which is convenient for fixed installation. The fixed seat 6 ensures the stability of the installation of the fixed seat 6. The upper en...

Embodiment 2

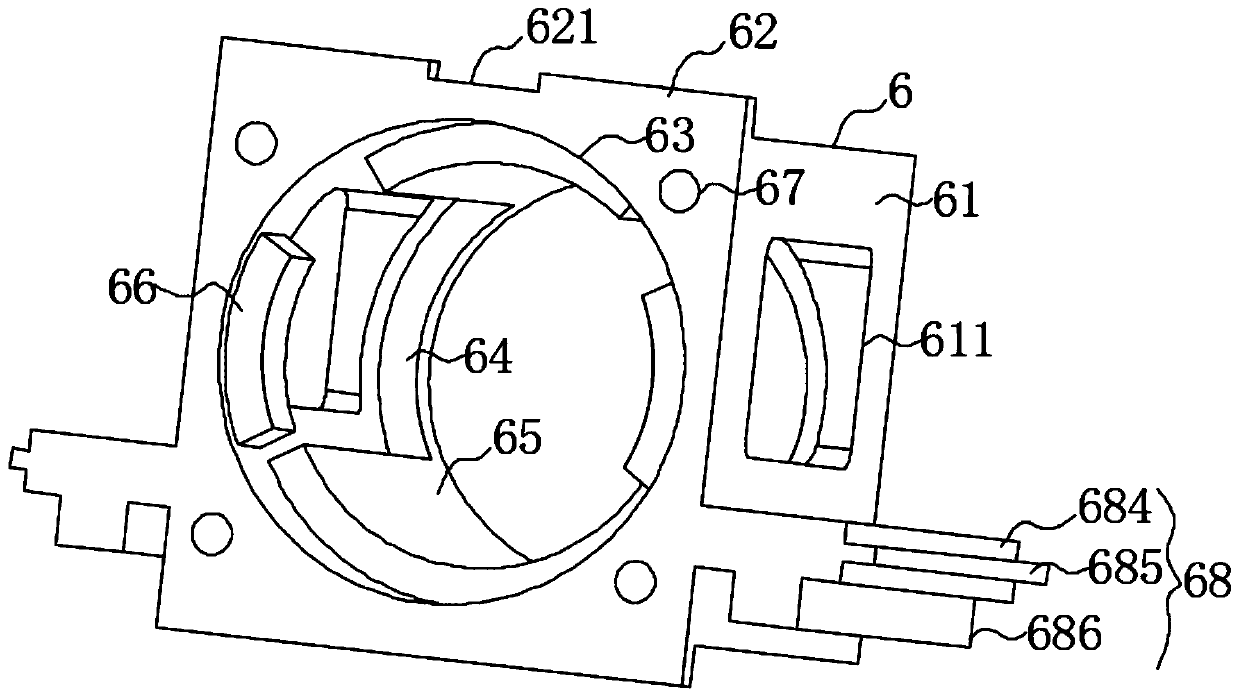

[0021] see figure 1 and image 3 , the present invention provides a technical solution: the installation wing 68 includes a support wing 684, a first slider 685 and a second slider 686, the support wing 684 is fixedly installed on the left and right side walls of the kit 61, the The first sliding block 685 and the second sliding block 686 are respectively disposed on the outer end and the bottom end of the supporting wing 684 . The first sliding block 685 and the second sliding block 686 are movably inserted into the inner cavity of the first sliding rail 71 and the second sliding rail 72 respectively. When installing the fixing seat 6, only the fixing seat 6 needs to be inserted into the upper chute correspondingly from front to back. 7 and the sliding groove 8, because the shape and size of the first slide block 685 and the second slide block 686 are the same as the shape and size of the first slide rail 71 and the second slide rail 72 inner cavity respectively, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com