Automatic double-head induction heating equipment

An induction heating equipment, double-head technology, applied in induction heating, induction heating control, induction heating device and other directions, can solve the problems of inability to meet processing requirements, low efficiency, etc., to achieve the effect of improving the degree of automation and reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

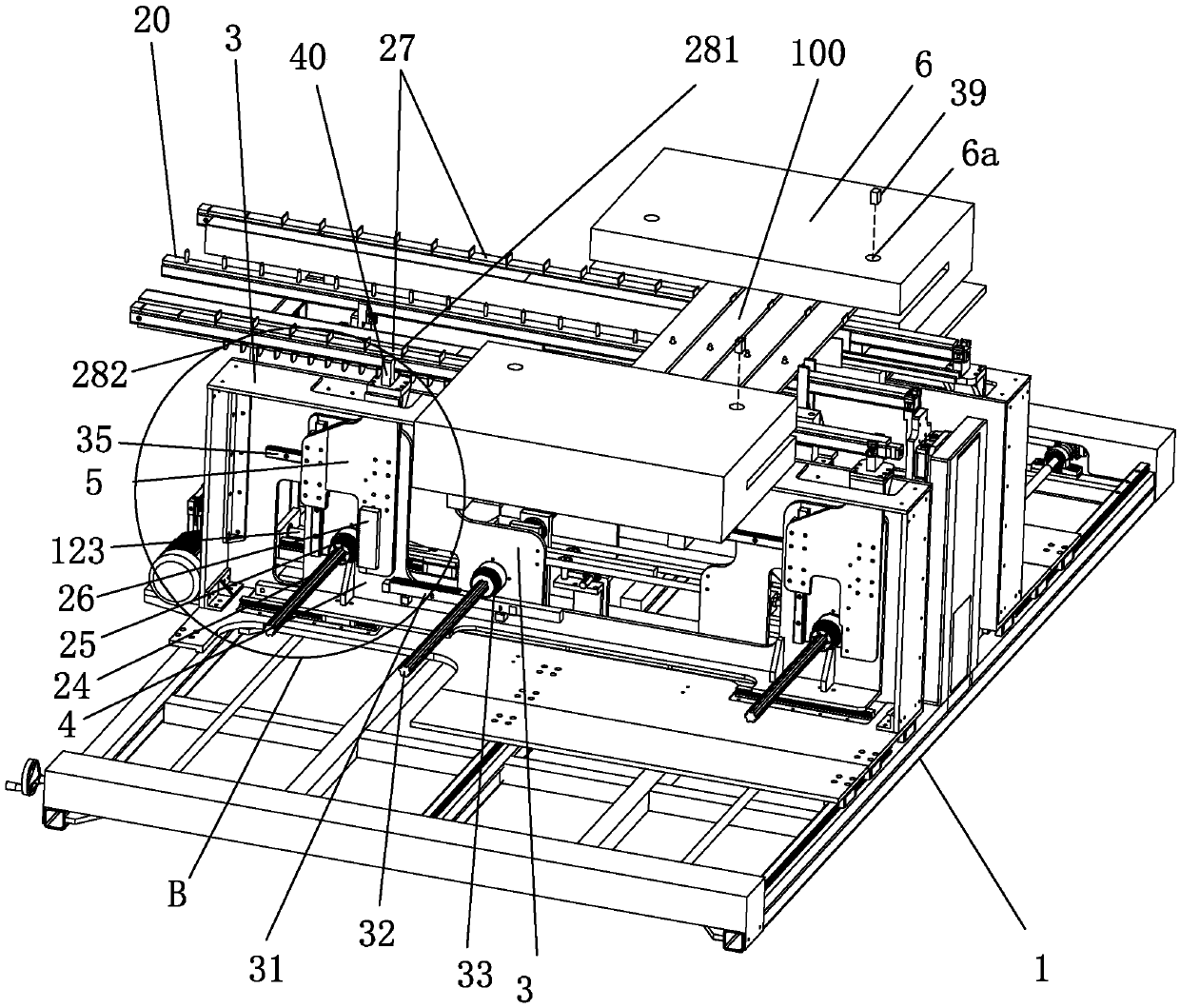

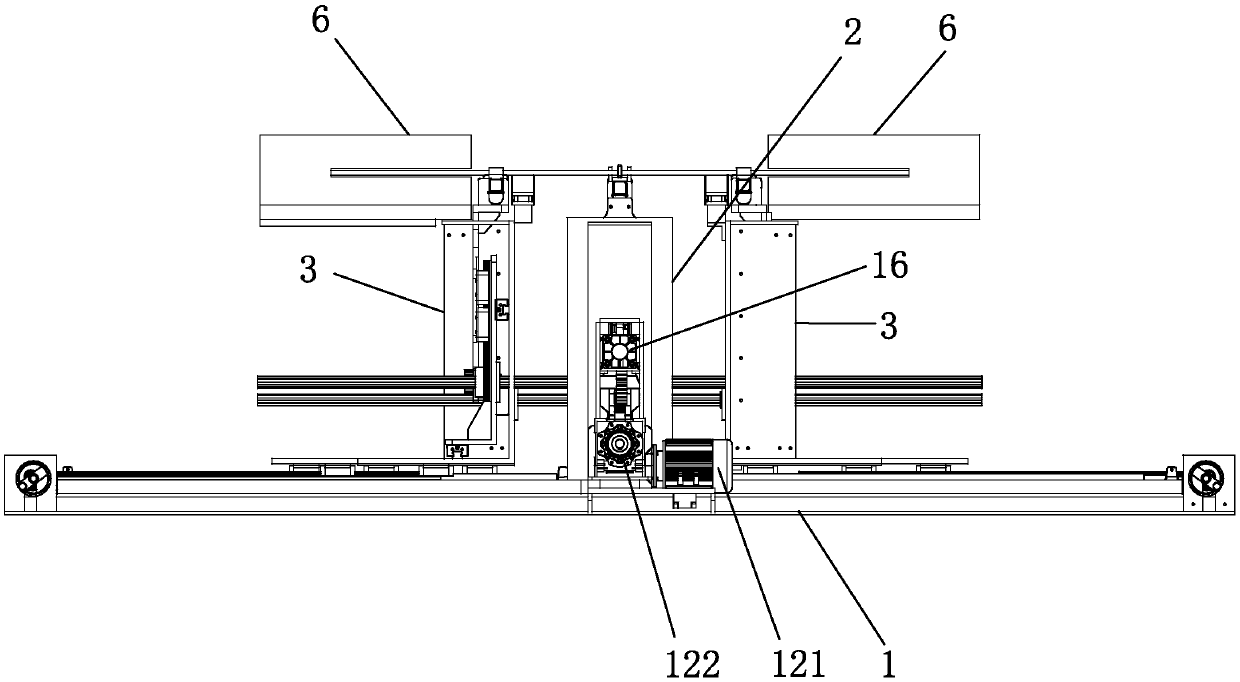

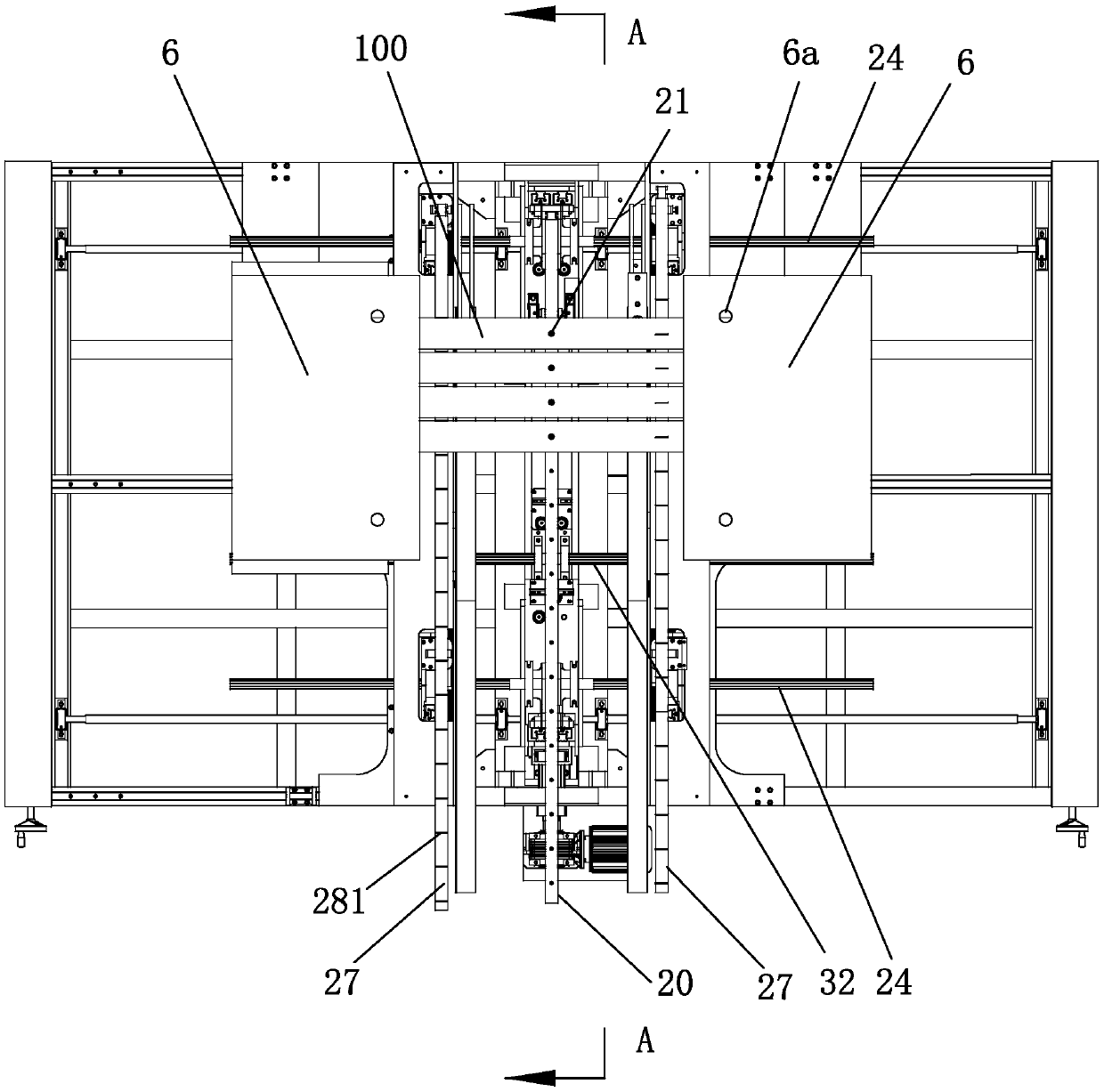

[0044] Example: figure 1 It is a kind of automatic double-head induction heating equipment disclosed by the present invention, such as figure 1 , figure 2 As shown, it includes a base 1, two mobile frames 3 are arranged on the base 1, a fixed frame 2 is arranged between the two mobile frames 3, and an induction furnace 6 is placed on the two mobile frames 3.

[0045] Such as Figure 4 As shown, the two ends of the fixed frame 2 are respectively fixed with a first horizontal guide rail 7 and a second horizontal guide rail 8; The mounting base 10 , the first mounting base 9 and the second mounting base 10 are fixedly connected through a connecting rod 11 . The fixing frame 2 is provided with a driving device 12 for driving the movement of the first mounting base 9 . Driving device 12 is made of motor 121, speed reducer 122, leading screw 123 and nut seat 124, and motor 121 drives speed reducer 122, and speed reducer 122 drives leading screw 123, and nut seat 124 is connec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap