Photocatalyst laminate

A technology of photocatalyst and laminate, which is applied in the direction of catalyst protection, catalyst activation/preparation, catalytic reaction, etc., can solve the problems of loss of photocatalytic function, decrease of surface hydrophilicity, and poor antifouling property, etc., to maintain photocatalysis The effect of function, high design and stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

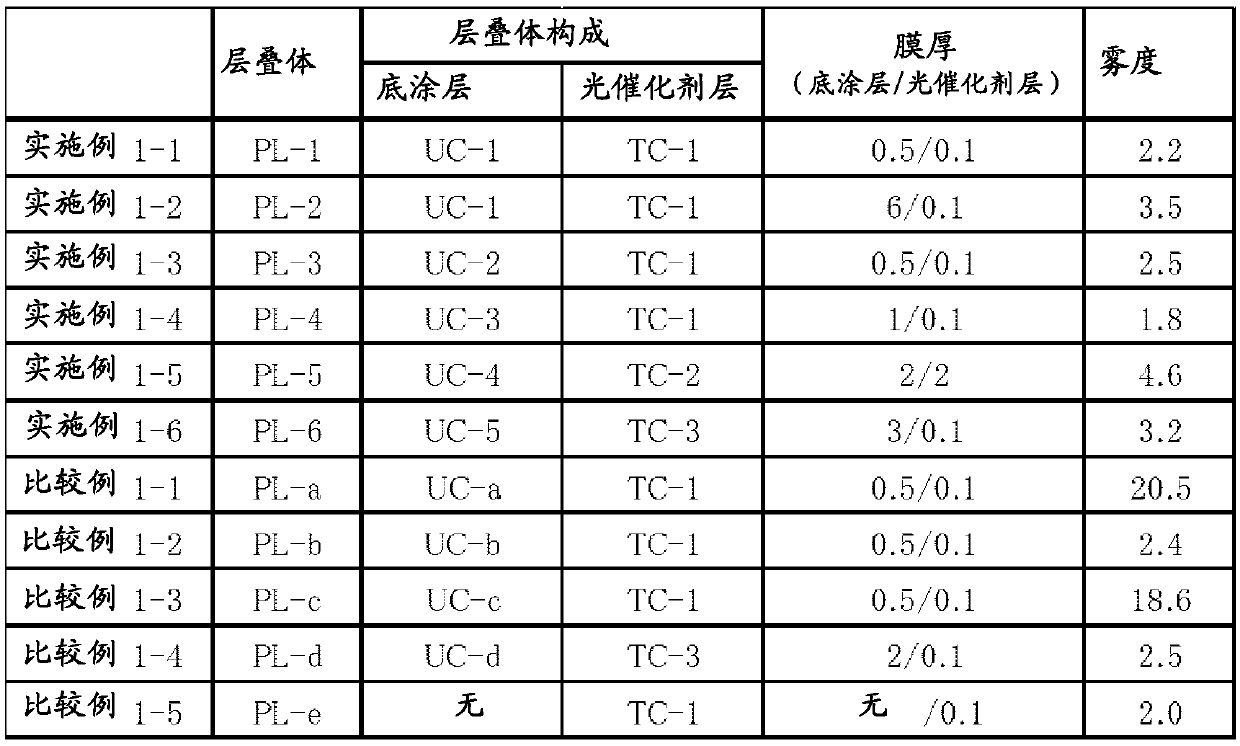

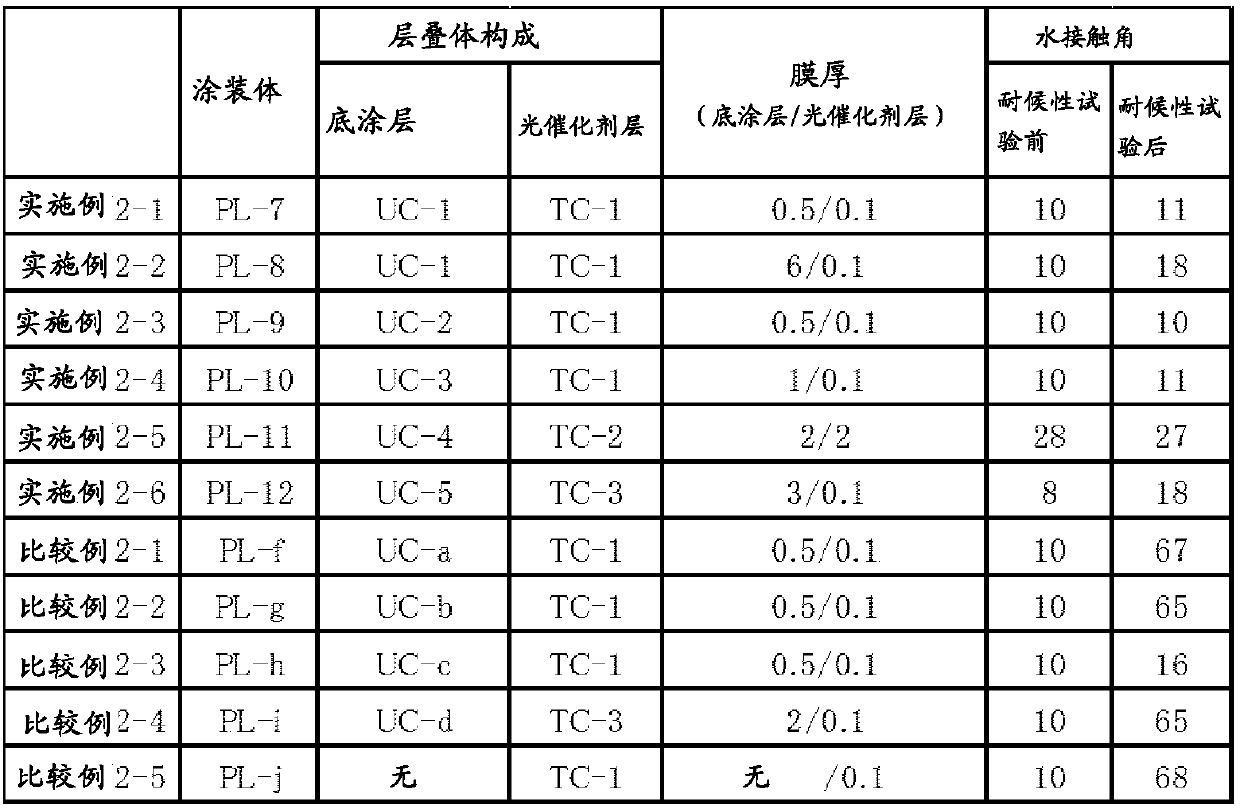

[0239] The following examples and comparative examples are given to describe the present invention more specifically, but the present invention is not limited to these examples.

[0240] [1] Preparation of core-shell particle dispersion and titanium oxide particle aqueous dispersion

Synthetic example 1

[0241] [Synthesis Example 1] Preparation of Aqueous Dispersion of Core-Shell Titanium Oxide Microparticles (TW-1)

[0242] An aqueous dispersion of core-shell type titanium oxide fine particles having tetragonal titanium oxide fine particles in which tin and manganese were solid-solved as a core and silicon oxide as a shell was prepared.

[0243] First, an aqueous dispersion containing titanium oxide fine particles serving as the core was prepared, and secondly, an active silicic acid solution prepared by treating sodium silicate with a cation exchange resin was mixed to prepare core-shell type titanium oxide fine particles having a shell of silicon oxide. water dispersion.

[0244] Add 33 g of a 50 mass % tin (IV) chloride solution (manufactured by Nippon Chemical Industry Co., Ltd.) to 660 g of a 36 mass % titanium (IV) chloride aqueous solution (manufactured by Ishihara Sangyo Co., Ltd., product name: TC-36) , Manganese (II) monoxide (manufactured by High Purity Chemical R...

Synthetic example 2

[0249] [Synthesis Example 2] Synthesis of Core-Shell Type Titanium Oxide Microparticle Ethanol Dispersion (TE-1)

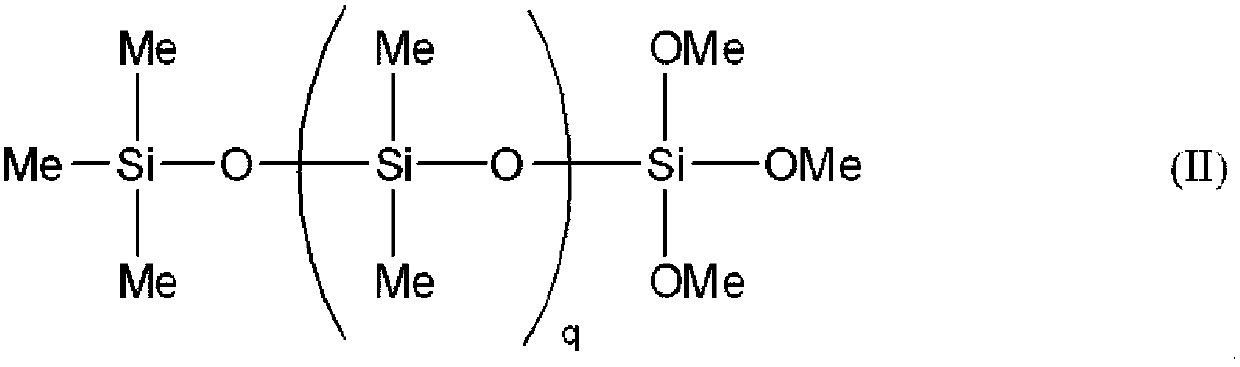

[0250] The core-shell type titanium oxide microparticles obtained in Synthesis Example 1 (TW-1, 300 g, solid content concentration of 10% by mass) and a sulfonic acid-based cationic ion-exchange resin (3 g) as a catalyst. Methyltrimethoxysilane (manufactured by Shin-Etsu Chemical Co., Ltd., product name "KBM-13", 225 g) was put there, and stirred vigorously (250 rpm). By stirring, the dispersion liquid reacted with the alkoxysilane, and it was observed that it became uniform. At this time, it was observed that the temperature of the dispersion liquid rose from 25°C to 52°C.

[0251] After heating and stirring for 2 hours so that the temperature of the dispersion liquid became 50° C., ethanol (750 g) was added to the dispersion liquid while stirring (250 rpm), and diluted. The diluted dispersion was introduced into an ultrafiltration machine, and 800 g of exudat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com