Removable valve bridges and valve actuation systems including the same

A technology for valve bridges and valves, which can be used in valve driving devices, engine components, combustion engines, etc., and can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

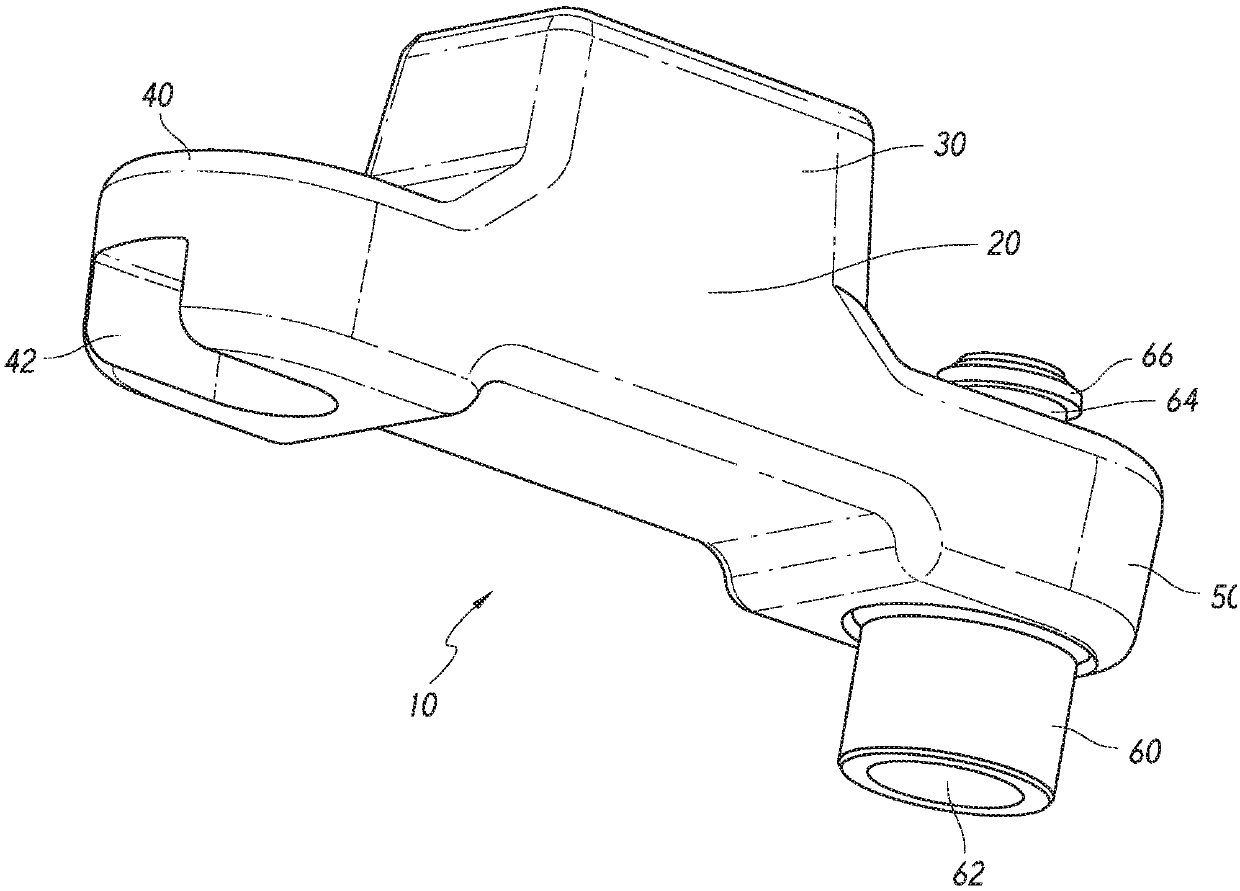

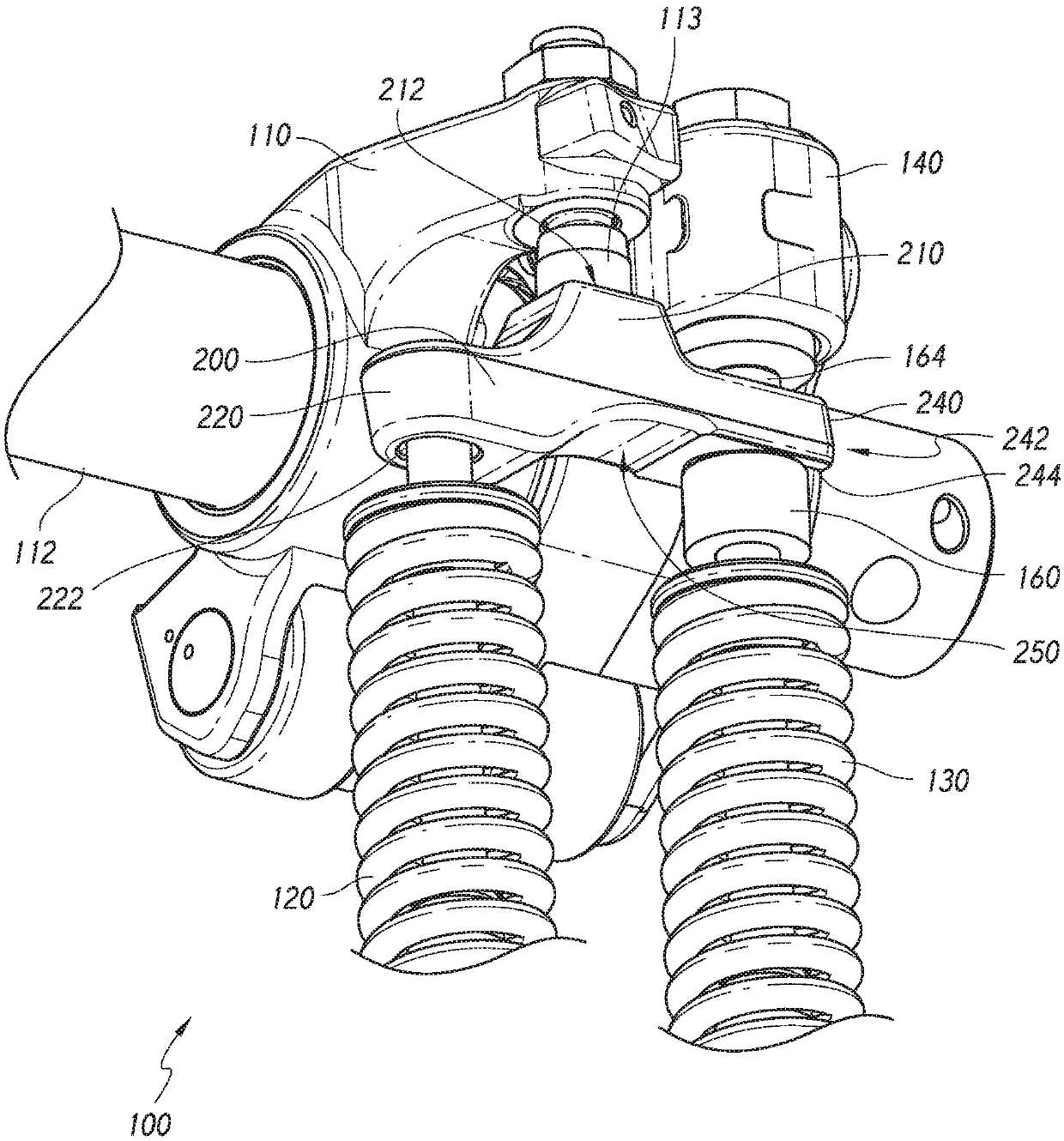

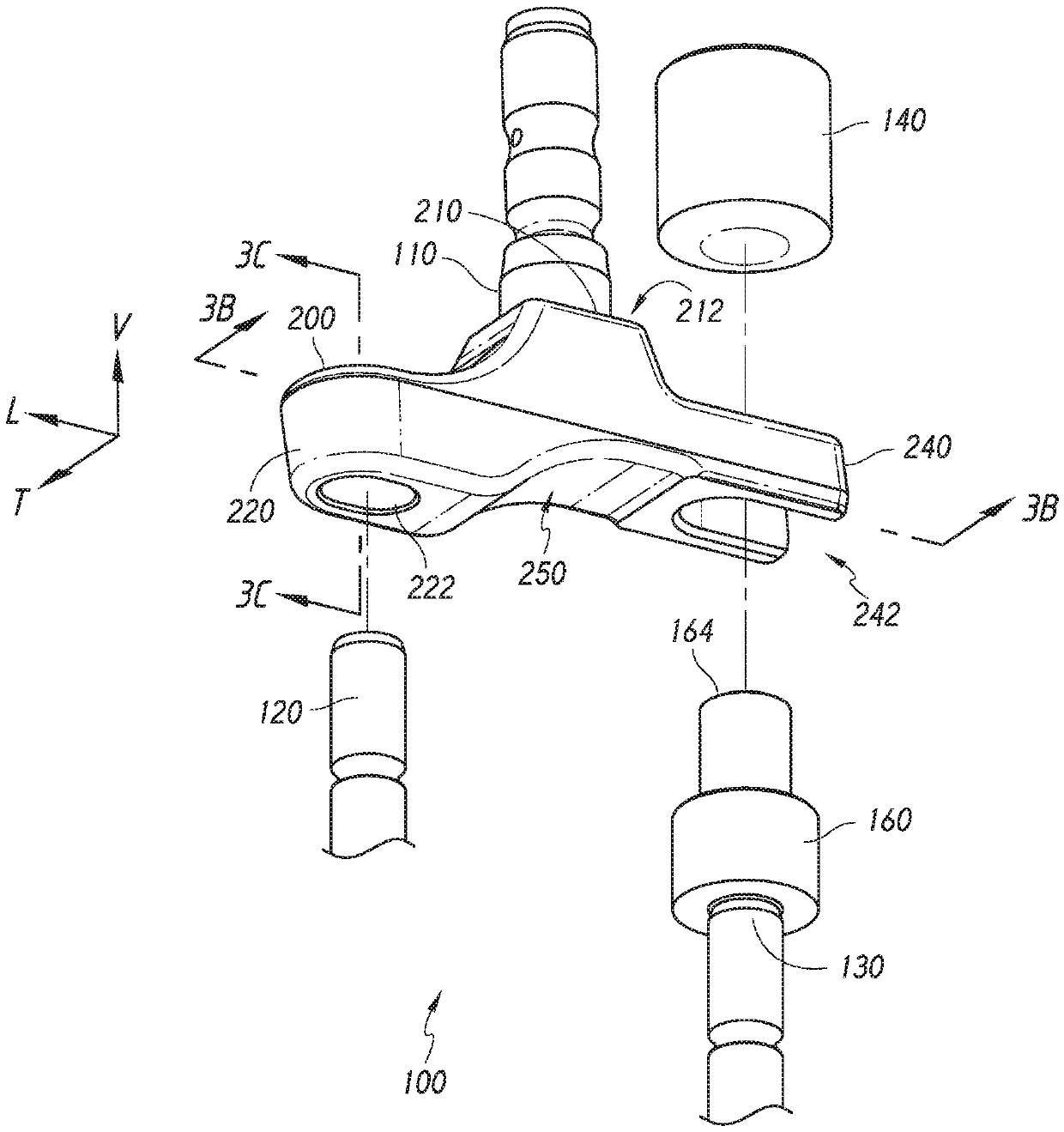

[0020] will now first refer to figure 2 , Figure 3A , Figure 3B , Figure 3C and Figure 4 Example valve bridges and actuation systems are described in accordance with aspects of the present disclosure. The directional terms "longitudinal", "transverse" and "vertical" will be used herein and are defined by Figure 3A Orthogonal axes "L", "T" and "V" in represent. The valve actuation system 100 may include a valve bridge 200, and the valve bridge 200 may include a main event rocker interface portion 210 for receiving motion from a main event rocker 110, the main event rocker 110 is connected with the auxiliary event rocker 110 as an auxiliary The auxiliary rocker 140 of the motion source together may be mounted for pivotal movement on the rocker axis 112 . As an alternative to the auxiliary rocker 140, the auxiliary motion source may comprise, for example, a master / slave hydraulic system. The first valve interface portion 220 and the second valve interface portion 240 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com