A chemical liquid stirring device with multiple rotation angles

A chemical liquid and stirring device technology, which is applied in the direction of mixers with rotating stirring devices, transportation and packaging, chemical instruments and methods, etc., can solve the problems of low stirring efficiency, achieve the effect of improving stirring efficiency and increasing stirring capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

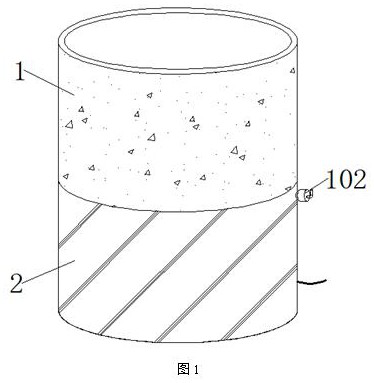

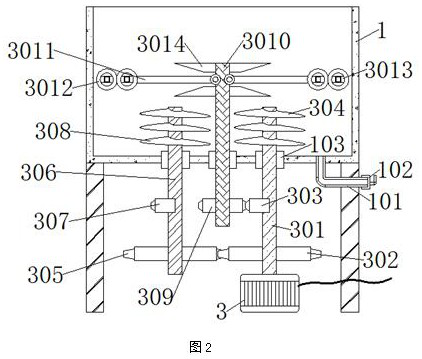

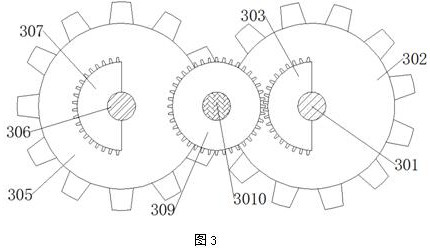

[0027] see Figures 1 to 7 Among them, in the embodiment of the present invention, a chemical liquid stirring device with multiple rotation angles includes a mixing drum 1, a transmission mechanism and a protective frame 2. The bottom of the mixing drum 1 is welded with a protective frame 2, and the protective frame 2 is provided with a transmission Mechanism, the bottom of the mixing drum 1 is embedded with a discharge pipe 101, and the discharge pipe 101 runs through the right side of the protective frame 2, the right side of the discharge pipe 101 is threaded with a threaded cover 102, and the bottom of the mixing drum 1 is embedded and welded There are three bearings 103; the transmission mechanism includes a motor 3, a rotating shaft 301, a driving gear 302, a driving half gear 303, a driving helical blade 304, a driven gear 305, a driven shaft 306, a driven half gear 307, a driven helical blade 308, Pinion 309, central shaft 3010, stirring rod 3011, stirring tube 3012, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com