Quick cleaning device for surface of wrench socket

The technology of a wrench socket and a cleaning device is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. It can solve the problems of time-consuming and labor-intensive manual cleaning, and the cleanliness cannot reach the level of painting, so as to increase the cleaning area, Improve the cleaning efficiency and facilitate the effect of popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

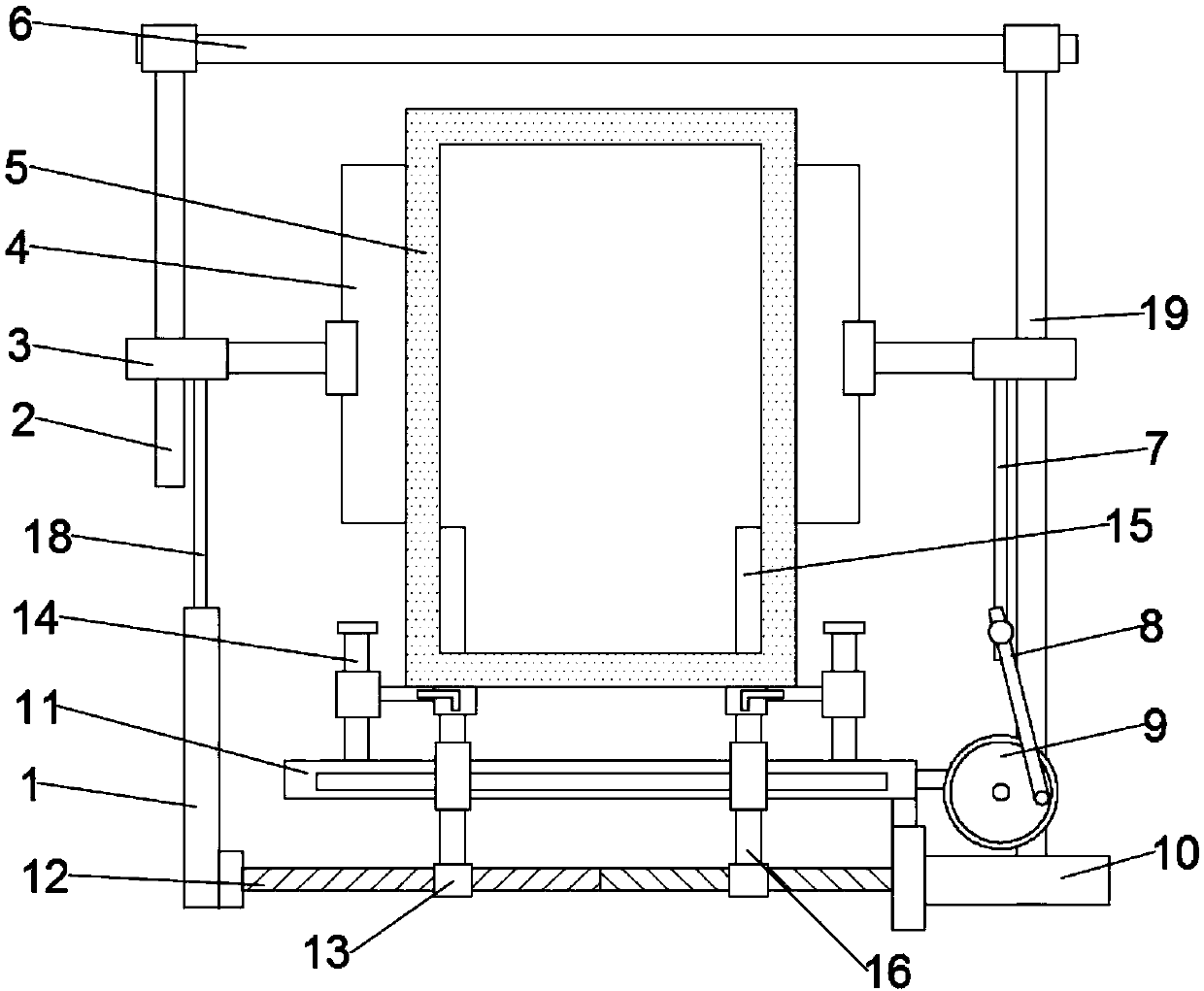

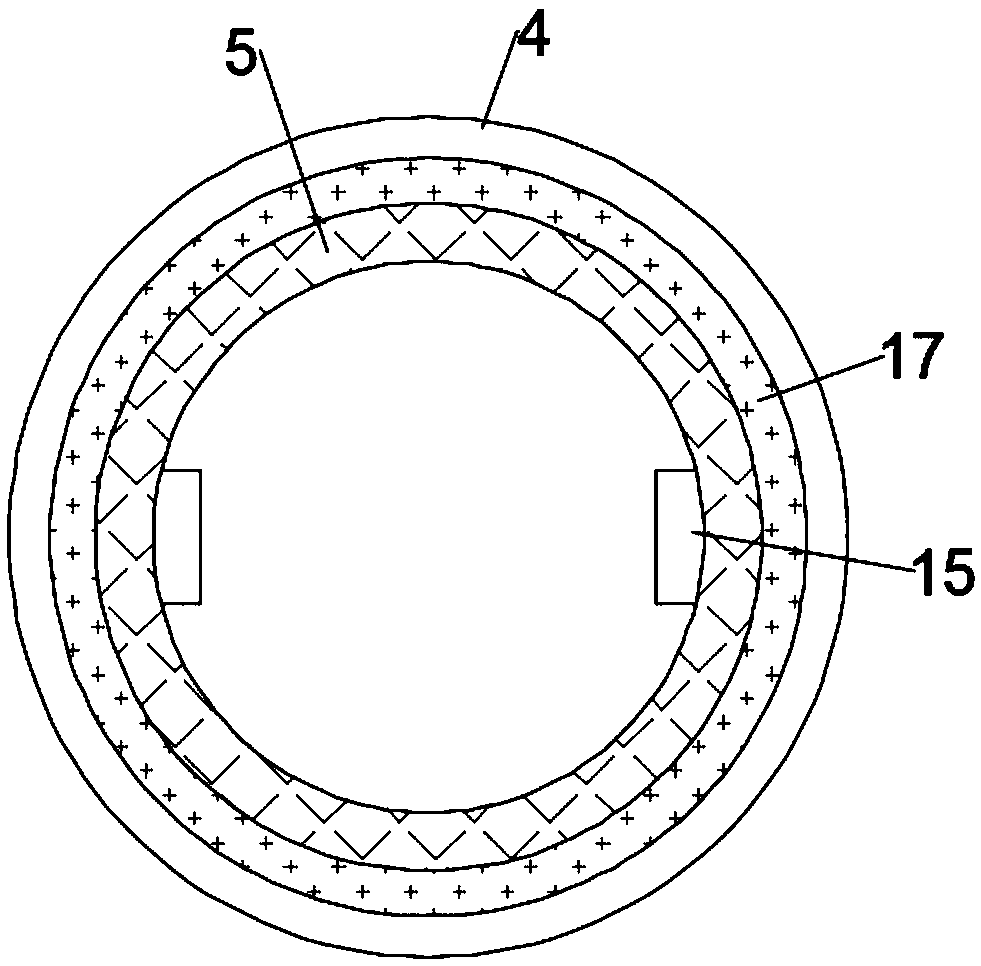

[0018] see Figure 1~2 , in an embodiment of the present invention, a device for quickly cleaning the surface of a wrench socket, comprising an annular cleaning block 4, a wrench socket 5, a connecting cross bar 6 and a support column 19, the upper end of the support column 19 is fixedly welded to connect the cross bar 6, The left end of the connecting cross bar 6 is fixedly welded with the guide bar 2, and the first slide block 3 is sleeved on the guide bar 2 and the support column 19, and the two first slide blocks 3 are located on the same horizontal line, and the first slide block 3 One end is fixedly welded ring-shaped cleaning piece 4 close to each other, and annular hairbrush 17 is installed on the inner wall of described ring-shaped cleaning piece 4, and wrench socket 5 is set in said ring-shaped cleaning piece 4, and described ring-shaped hairbrush 17 and described wrench socket 5 abut Then, the setting of the ring-shaped brush 17 can realize sufficient cleaning of th...

Embodiment 2

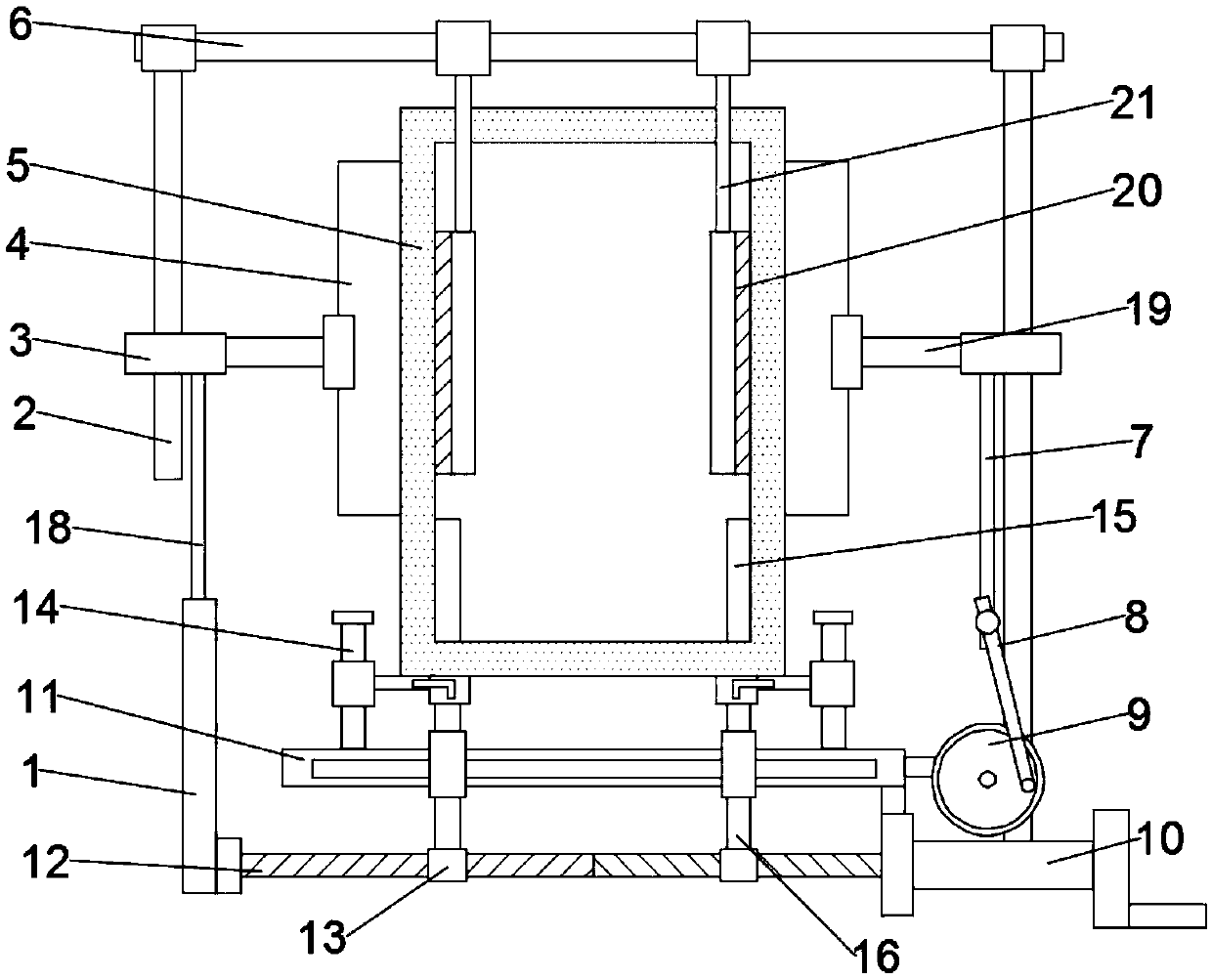

[0026] see image 3 , in the embodiment of the present invention, two second connecting rods 21 are symmetrically installed on the connecting cross bar 6, and the lower ends of the second connecting rods 21 extend into the inner cavity of the wrench socket 5, and the second connecting rods 21 The inner wall cleaning brush 20 is fixedly installed on the side of the rod 21 close to the inner wall of the wrench sleeve 5. The setting of the inner wall cleaning brush 20 can realize sufficient cleaning of the inner wall of the wrench sleeve 5. Other structures in this embodiment are the same as those in Embodiment 1. same.

Embodiment 3

[0028] A wrench socket painting processing equipment, comprising the device for quickly cleaning the surface of a wrench socket as described in Example 2.

[0029] The working principle of the present invention is: when the wrench sleeve needs to be cleaned, the wrench sleeve is placed outside the fixing plate 15, and then the rotating shaft 10 is rotated to realize the fixing of the wrench sleeve, and then the drive motor is started, The drive motor starts to drive the runner 9 to rotate, and the runner 9 drives the second hinged rod 8 and the first hinged rod 7 to move up and down, thereby realizing driving the ring-shaped cleaning block 4 and the ring-shaped brush 17 up and down Move, help to increase the cleaning area of the outer wall of the wrench sleeve 5, and improve the cleaning efficiency at the same time, the present invention can realize the sufficient cleaning of the inner and outer walls of the wrench sleeve, thereby facilitating the painting operation of the wr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com