Frame structure of electric vehicle

A frame structure and electric vehicle technology, applied in the field of electric vehicles, can solve problems such as affecting the appearance, not being usable, and not satisfying high-end customers, and achieving the effect of beautiful appearance, reasonable structure, and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

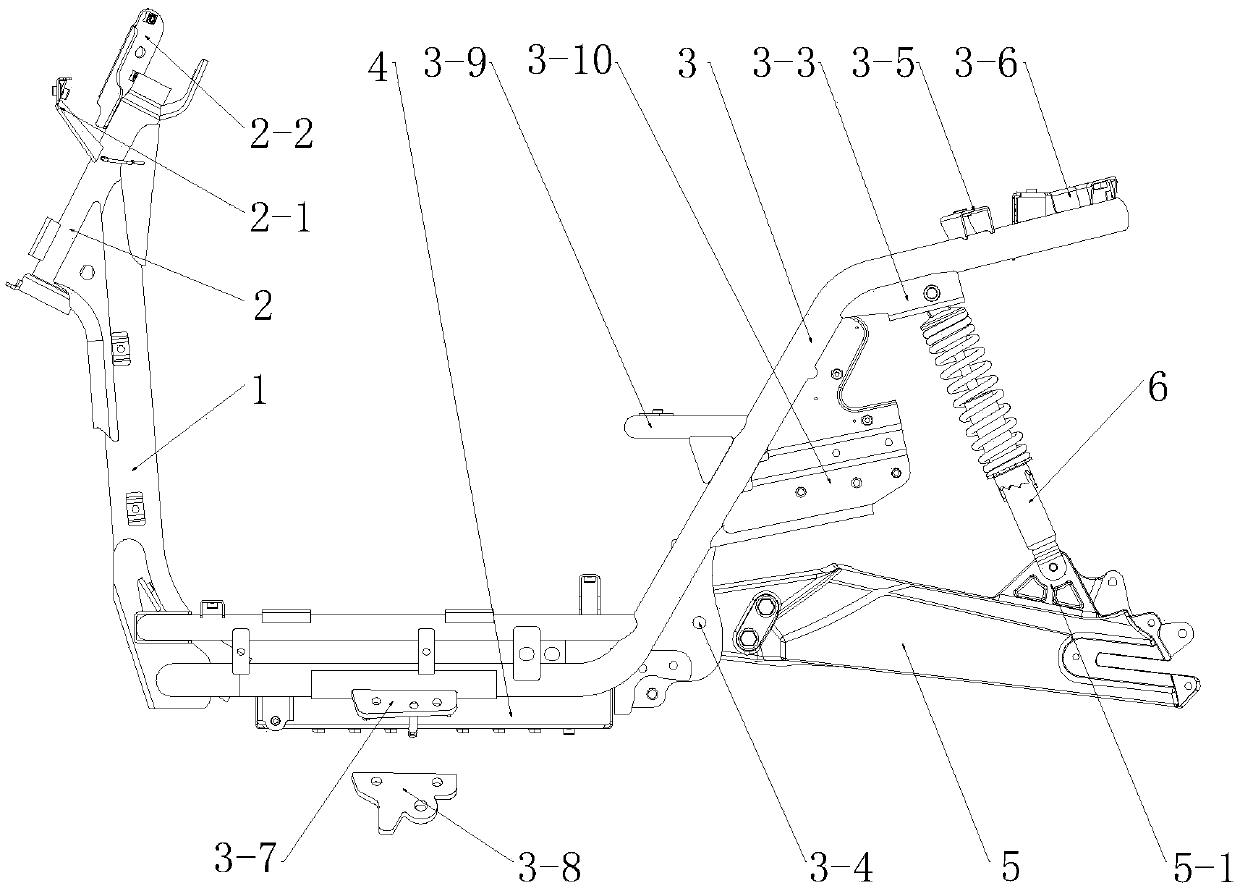

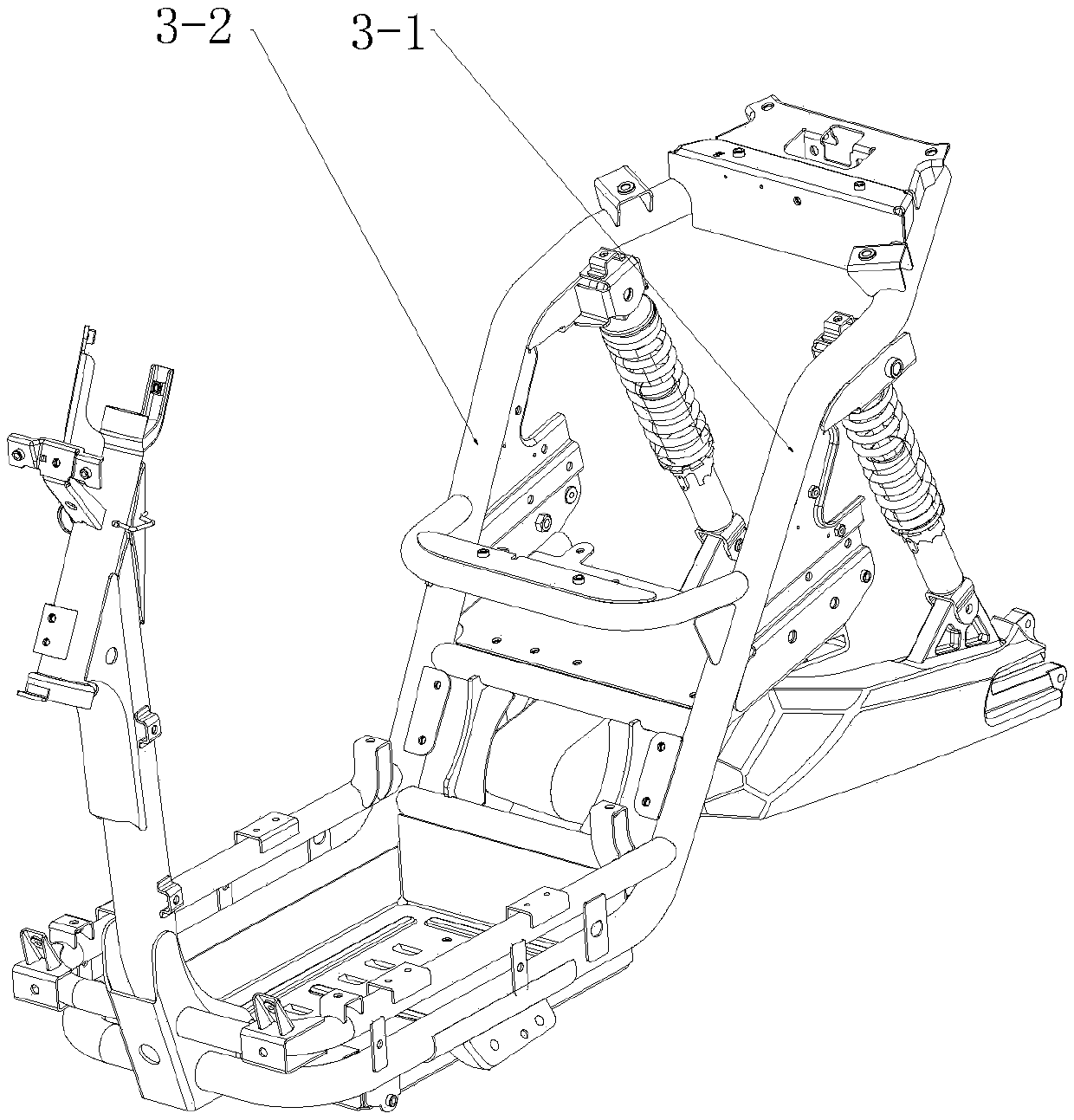

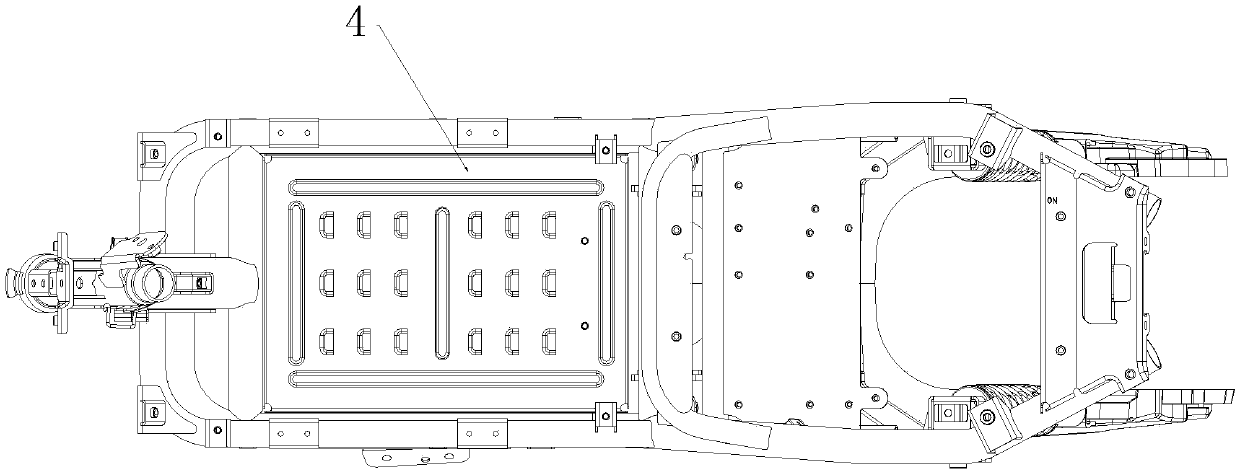

[0016] a kind of like Figure 1 to Figure 3 The shown electric vehicle frame structure includes a main beam 1, a frame riser 2 fixed on the main beam 1, a main frame 3 fixedly connected to the main beam 1, and the main frame 3 It is mainly composed of a left main pipe 3-1 and a right main pipe 3-2. It is characterized in that: the main frame 3 includes a front part fixed to the main beam 1 and arranged horizontally, integrally formed on the front part and inclined in turn The middle part and the rear part of the setting, wherein, the front part of the main frame 3 is fixed with a battery box frame 4; the lower end of the middle part of the main frame 3 is connected with a flat fork 5 through a flat fork shaft 3-4; the left main frame 3-1, the inner side of the rear part of the right main pipe 3-2 is respectively equipped with an upper sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com