Aerosol can automatic cover sealing device

An automatic technology for aerosol cans, applied in closures, bottle/container caps, and capping containers with caps, etc., can solve the problems of low capping efficiency of aerosol cans, improve capping efficiency, and improve positioning stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

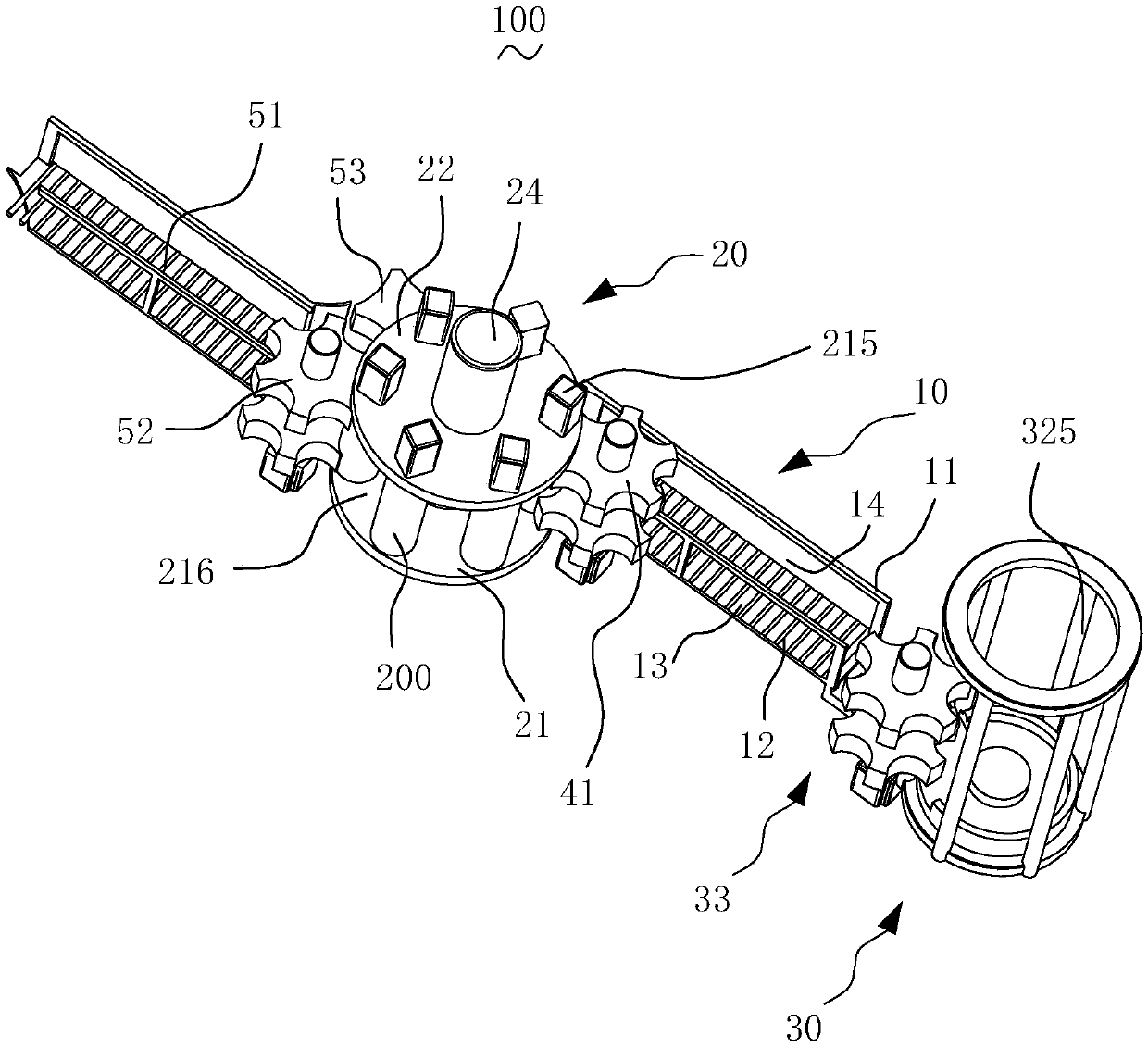

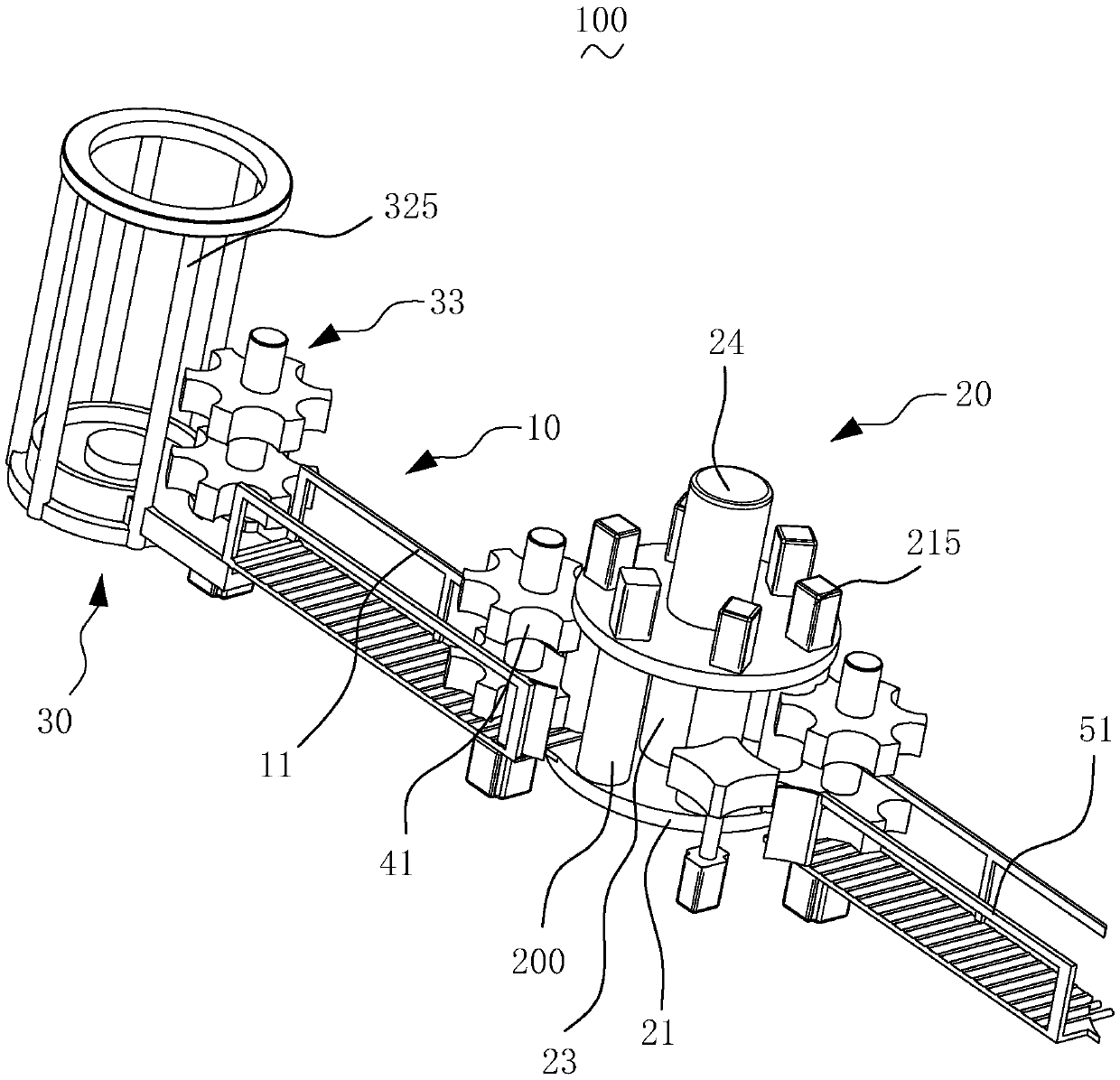

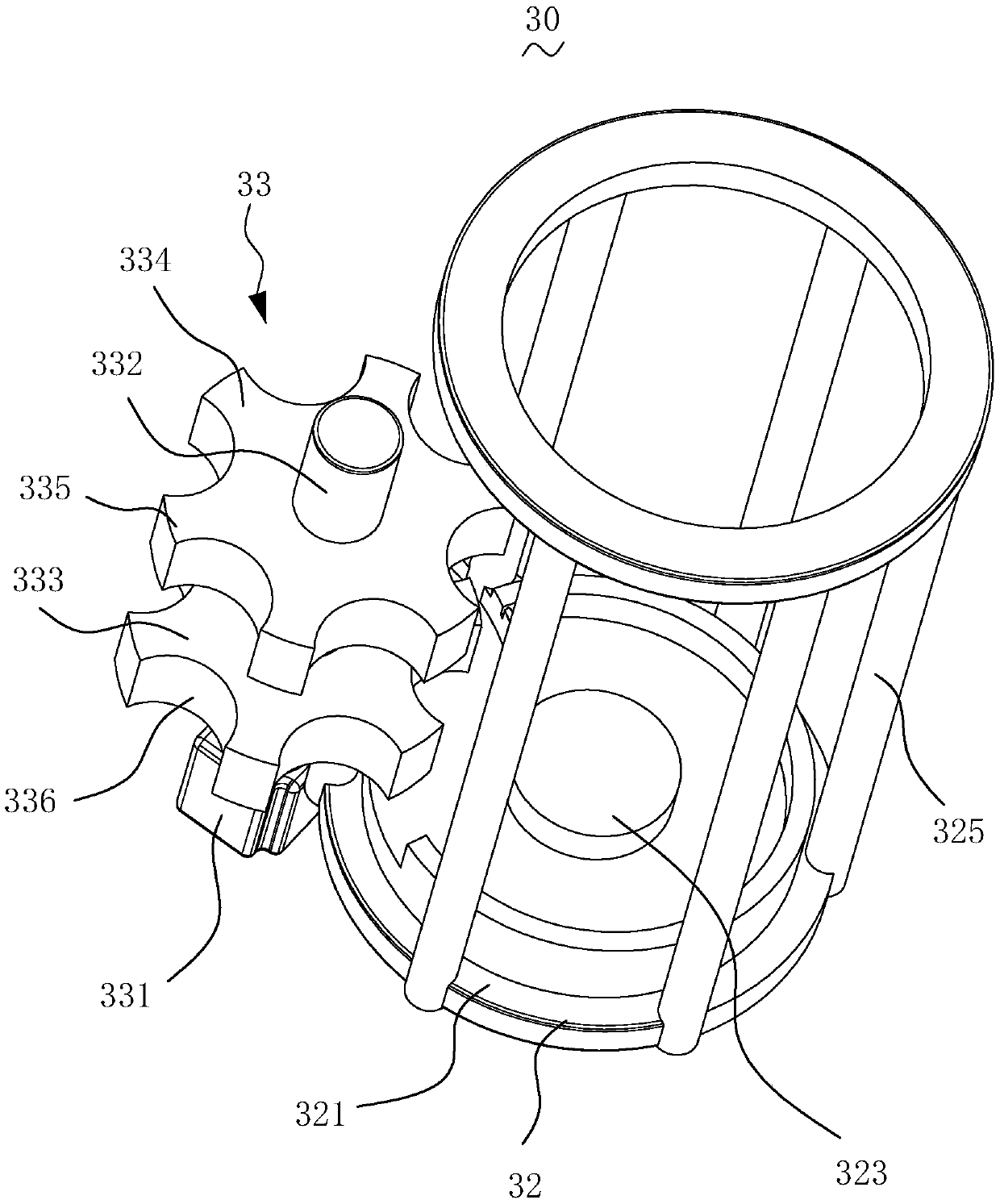

[0035] see Figure 1 to Figure 2 , an aerosol can automatic capping equipment 100, including a conveying track 10 and a capping assembly 20, the conveying track 10 includes two railings 11 and a plurality of conveying columns 12, the two railings 11 are arranged parallel to each other, so The plurality of delivery columns 12 are arranged between the two railings 11, the plurality of delivery columns 12 are arranged parallel to each other, the cover assembly 20 is arranged at one end of the delivery track 10, the cover assembly 20 includes a first positioning ring 21, a second positioning ring 22 and a connecting column 23, the first positioning ring 21 and the second positioning ring 22 are spaced apart from each other, and a plurality of seals are arranged on the first positioning ring 21 Cover the power part 215, the bottom of the first positioning ring 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com