Special-shaped curved surface quasi-triaxial fabric, knitting process method thereof and application of fabric

A technology of three-way fabrics and special-shaped curved surfaces, which is applied in the direction of braided fabrics, hand-woven fabrics, textiles, and papermaking, can solve problems such as inconsistent dipping, fiber damage, and uneven cover density, and achieve high reliability of mechanical properties and overcome Fiber damage, effect of achieving designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] The weaving process method of the special-shaped curved surface quasi-three-way fabric provided by the present invention comprises the following steps:

[0029] 1) Core mold making

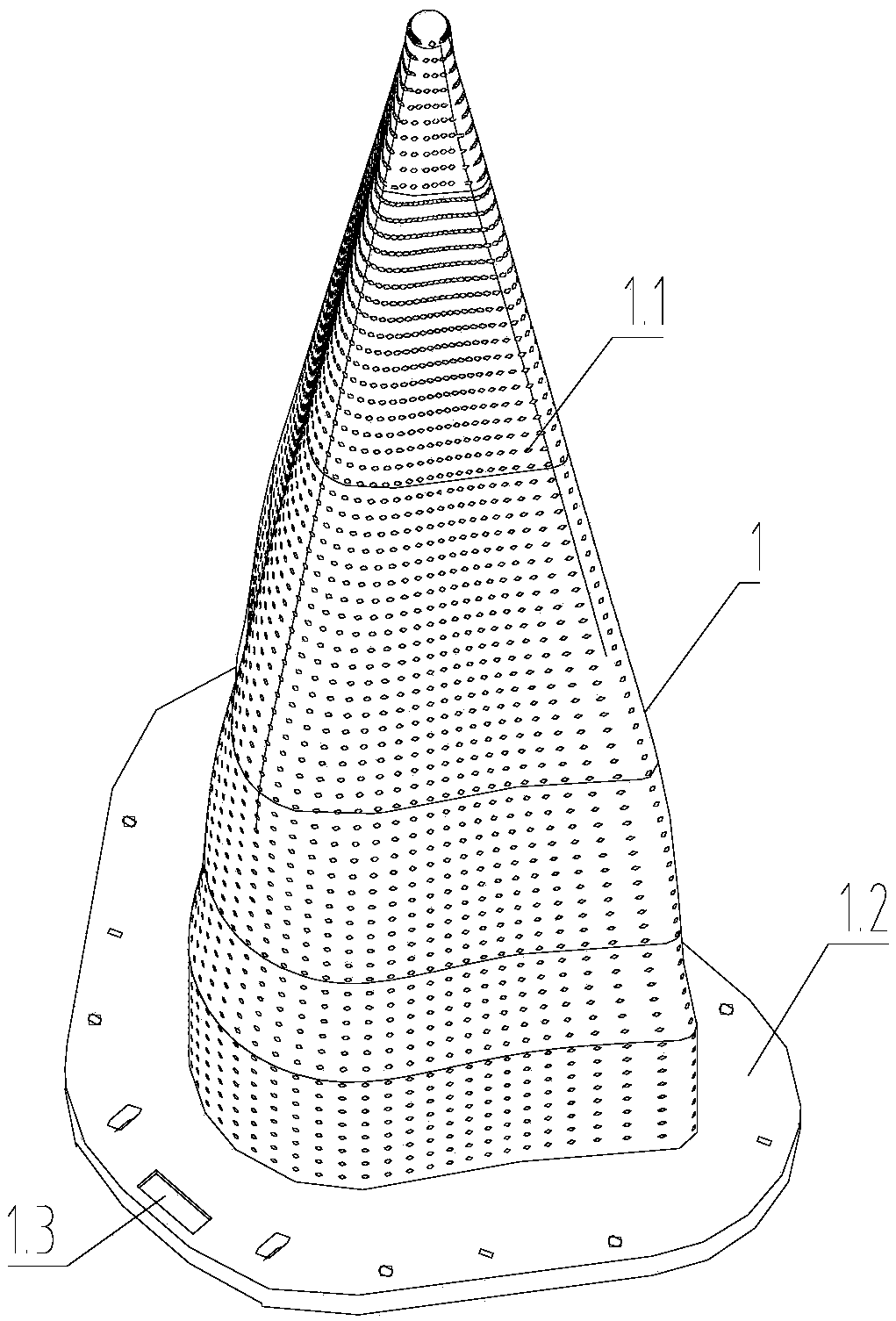

[0030] According to the shape of the radome, the core mold (1) is made of polytetrafluoroethylene, such as figure 1 As shown, the mandrel (1) is a hollow structure, its lower part is provided with a skirt (1.2), and a number of positioning holes (1.3) are provided on the skirt (1.2), among which the positioning hole (1.3) located in the middle of the protruding side of the bottom is a rectangle. According to the needs of the fabric structure, a 1.5mm×1.5mm pinhole (1.1) matrix is formed on the mandrel (1).

[0031] 2) Needle insertion

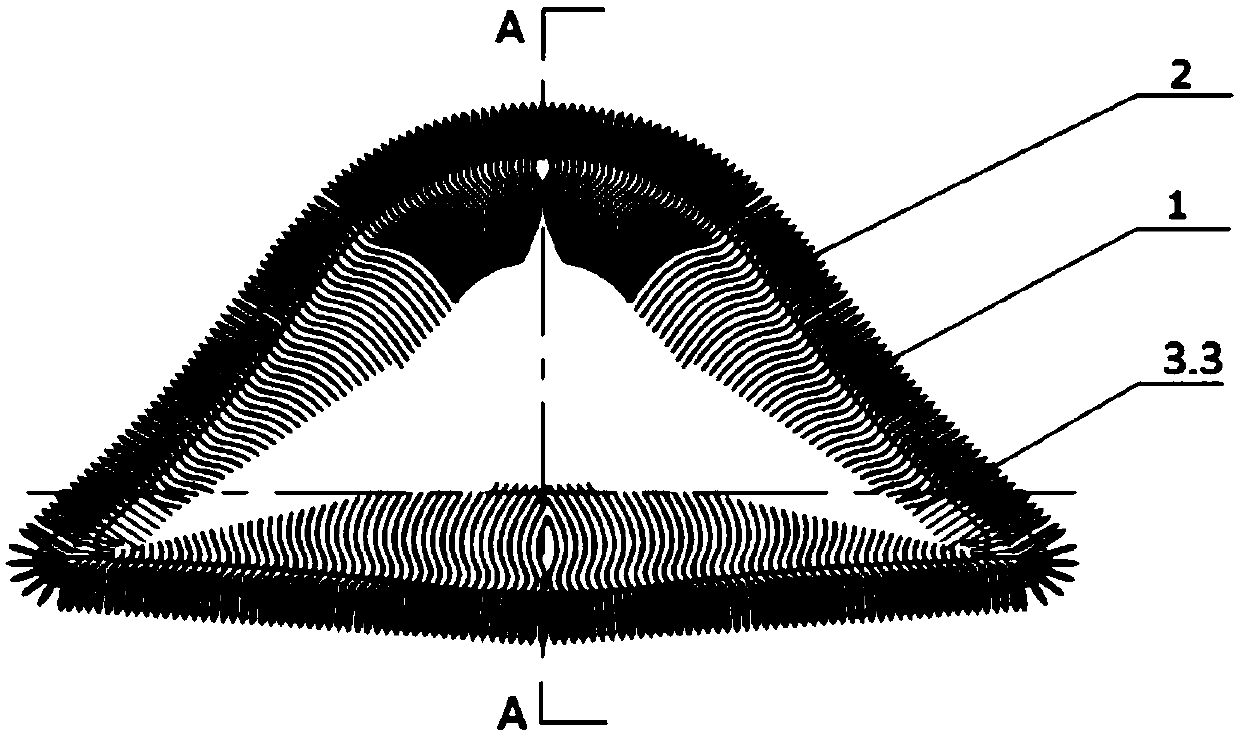

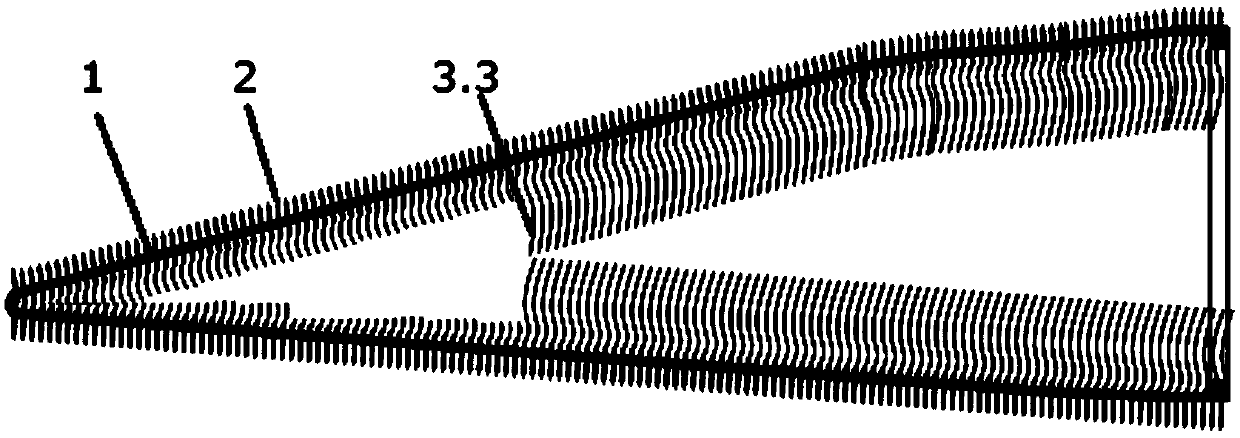

[0032] Such as figure 2 , image 3 As shown, the tail of the steel needle (2) is pre-punched through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com