Direct-cooling refrigerator defrosting function control method

A control method and the technology of direct cooling refrigerators, which are applied in defrosting, household refrigeration devices, cooling fluid circulation devices, etc., can solve problems such as food deterioration, affect product competitiveness, and increase the temperature in the box, so as to prevent food damage and increase Defrosting pause and resume function to ensure clean defrosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

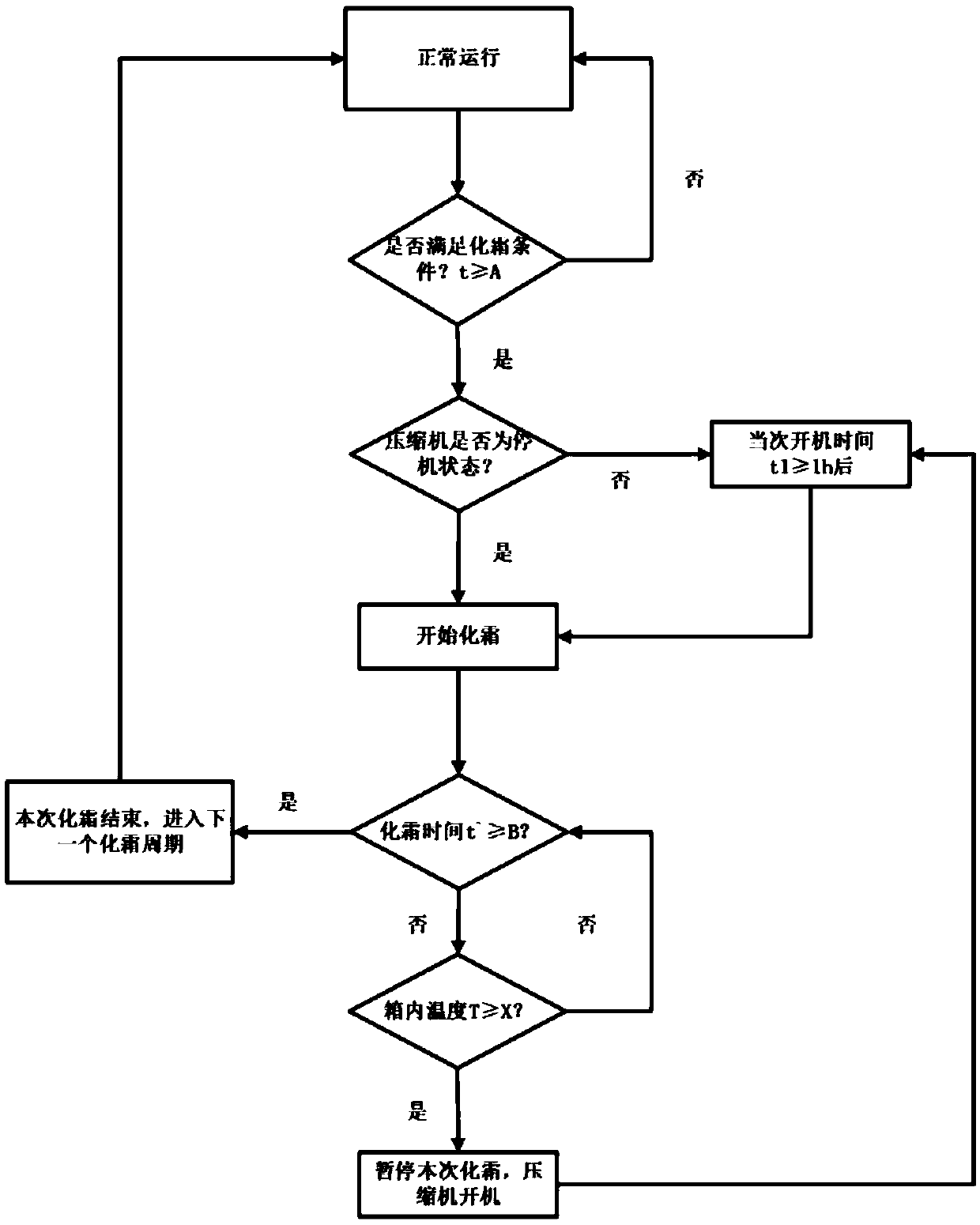

[0031] Such as figure 1 As shown, Embodiment 1 provides a low-cost defrosting method for a direct cooling refrigerator, and at the same time, this method can avoid food deterioration caused by excessive refrigerator temperature during the defrosting process.

[0032] A method for controlling the defrosting function of a direct cooling refrigerator, comprising the following steps:

[0033] When a defrost cycle starts, the compressor start-up time t 1 and refrigerator opening time t 2 Detect and calculate, both according to the weight coefficient α 1 = 1, α 2 = 120 After accumulation, the defrosting judgment time t(t=∑α 1 t 1 +∑α 2 t 2 ). When the converted defrosting judgment time t reaches A=24h (t≥24h), it is considered that the refrigerator meets the defrosting condition, and the defrosting process is ready to start.

[0034] Determine the operating state of the compressor at this time. If the compressor is in the stop state, it will directly enter the defrost stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com