An on-site part angle measuring device and method

An angle measurement device and parts technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of difficult identification and deviation of photographers, and achieve the effect of easy angle measurement, easy observation, and convenient remote diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The on-site part angle measuring device according to the preferred embodiment of the present invention includes: a magnetic base and a cylindrical structure, the cylindrical structure is vertically arranged on the magnetic base, and is connected with the magnetic base as an integral structure; wherein, the lower end of the cylindrical structure is close to the cylinder A light-transmitting hole is provided at the connection portion between the cylindrical structure and the magnetic base 1, and the light-transmitting hole penetrates the cylindrical structure.

[0028] In the above solution, the diameter of the light-transmitting hole is smaller than the diameter of the cylindrical structure. The cylindrical structure is arranged vertically at the center of the magnetic base.

Embodiment 2

[0030] Such as Figure 2 to Figure 4 As shown, the on-site component angle measuring device according to the preferred embodiment of the present invention includes: a magnetic base 1 and a cylindrical structure 2, the cylindrical structure 2 is vertically arranged on the magnetic base 1, and is connected with the magnetic base 1 as an integral structure. Preferably, the cylindrical structure 2 is vertically arranged at the center of the magnetic base 1 . Wherein, the lower end of the cylindrical structure 2 is provided with a light-transmitting hole 3 near the connection between the cylindrical structure 2 and the magnetic base 1, the light-transmitting hole 3 runs through the cylindrical structure 2, and the diameter of the light-transmitting hole 3 is smaller than that of the cylindrical structure 2 diameter of. Cross wires 4 are arranged in both the inner hole of the upper end surface and the inner hole of the lower end surface of the cylindrical structure 2 .

[0031] In...

Embodiment 3

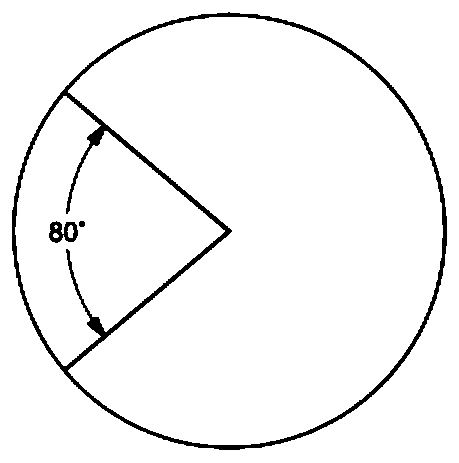

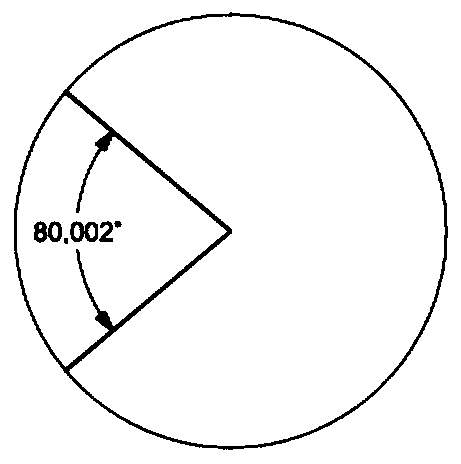

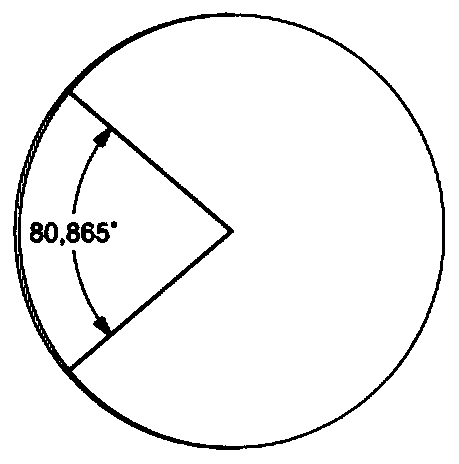

[0033] Such as Figure 6 As shown, the present invention also provides a method for on-site part angle measurement, including the following steps: step 601: attach the on-site part angle measurement device to the part to be measured through a magnetic base; step 602: connect the optical axis of the shooting device to the on-site The axis of the cylindrical structure of the part angle measuring device is kept aligned; step 603: observe the coaxiality of the inner hole of the upper end surface of the cylindrical structure and the inner hole contour of the lower end surface to determine whether the optical axis of the shooting device is perpendicular to the part to be measured; step 604: When it is observed that the part to be tested is perpendicular to the optical axis of the photographing device, take a photo of the part to be tested to obtain a photo to be tested; and Step 605: Measure the corresponding angle in the photo to be tested by software.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com