Dynamic modeling method of machine tool spindle-tool holder connection structure based on ultrasonic testing

A dynamic modeling and connection structure technology, applied in computer-aided design, instrumentation, geometric CAD, etc., can solve problems such as noise sensitivity, and achieve high accuracy and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

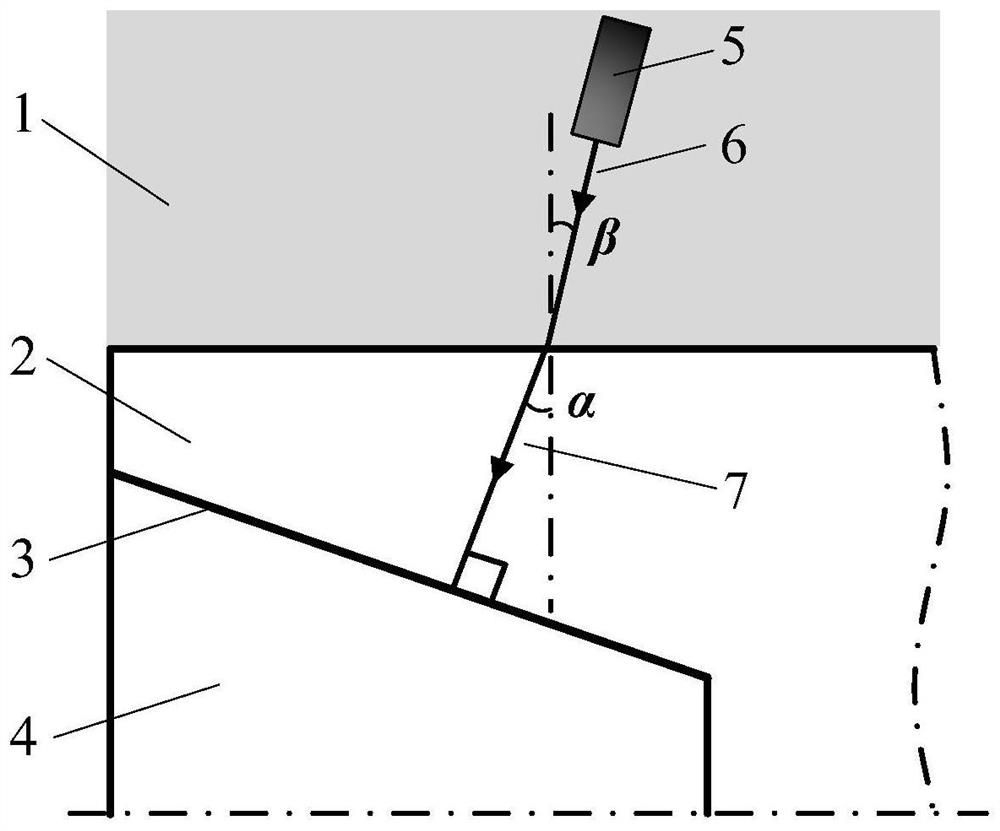

[0042] Tool holders with a taper of 7:24 are widely used in the spindle system of machine tools. The contact stiffness detection method of the present invention will be further described in detail in conjunction with the accompanying drawings by taking the 7:24 spindle-tool holder joint surface as an example.

[0043]Step 1. In a typical spindle-tool holder connection structure, the outer surface of the spindle taper hole is a cylindrical surface, while the spindle taper hole-tool holder joint surface is conical.

[0044] The material of the tested piece in this embodiment is alloy steel, and the contact surface is ground. Refer to attached figure 1 , since the outer surface of the tapered hole test piece is generally a cylindrical surface and the conical joint surface is not parallel, in order to achieve vertical incidence, it is necessary to adjust the tilt an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com