Visual and active interaction-based packaging box segmentation error detection and correction method

An active interaction and packing box technology, applied in the field of logistics, can solve problems such as high failure rate, over-segmentation, and unclear boundaries of boxes, and achieve the effect of improving robustness and avoiding crashes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

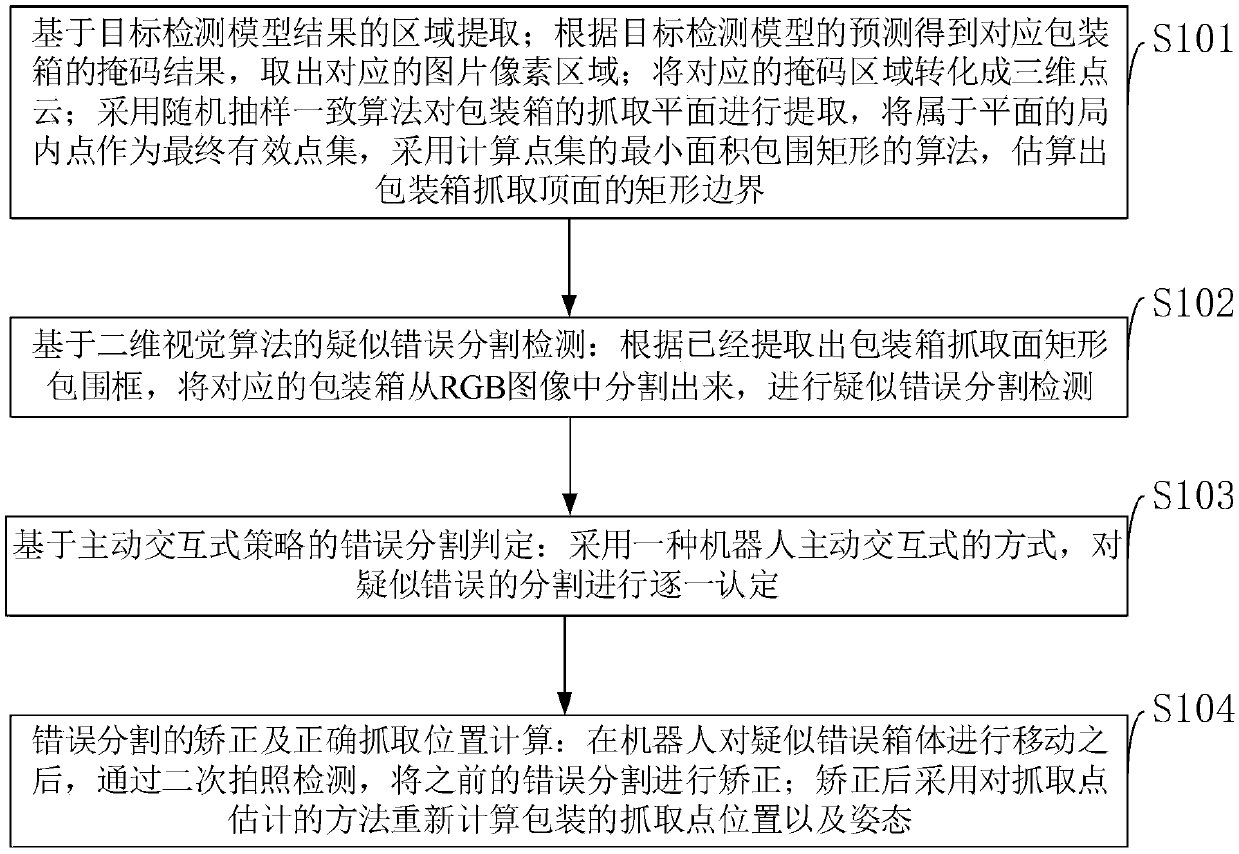

[0089] The detection and correction methods for packaging box segmentation errors based on vision and active interaction provided by the embodiments of the present invention are: region extraction based on target detection model results; suspected incorrect segmentation detection based on two-dimensional vision algorithms; error detection based on active interactive strategies Segmentation judgment; correction of wrong segmentation and calculation of correct grasping position.

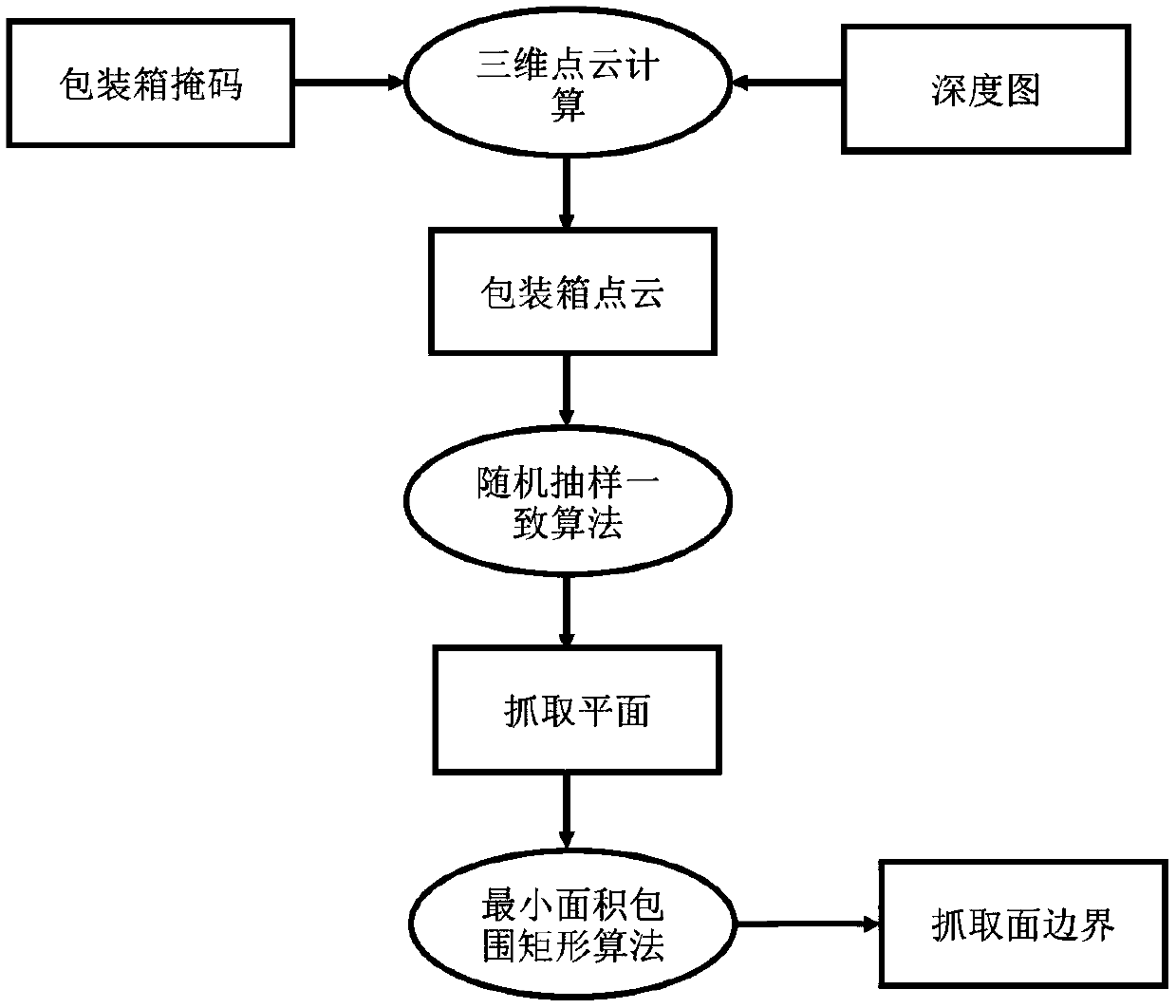

[0090] (1) Region extraction based on target detection model results

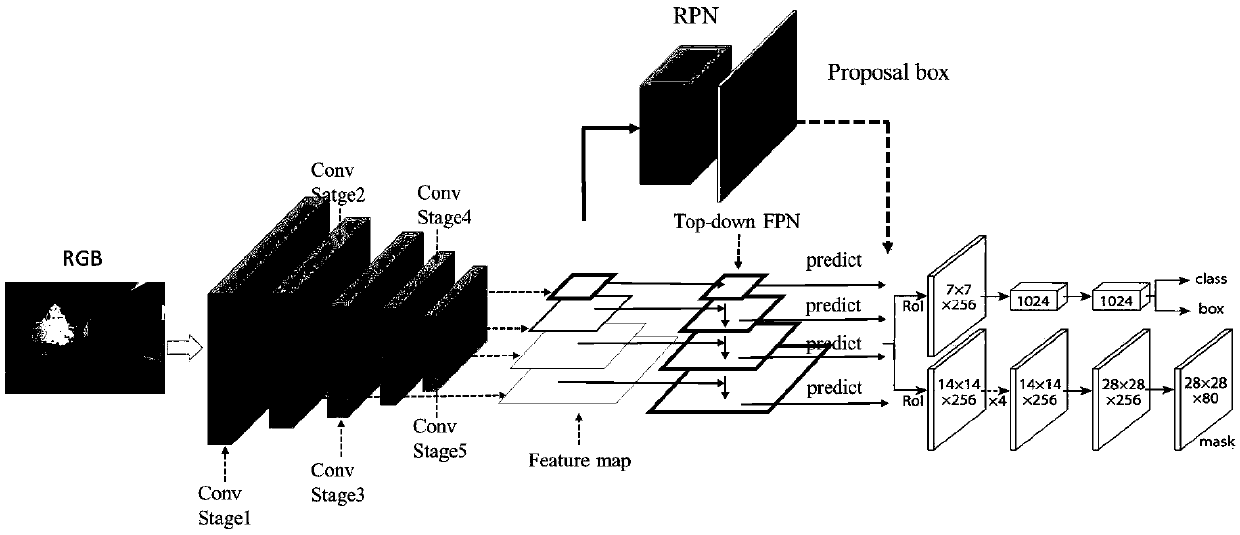

[0091] like figure 2 As shown, a schematic diagram of the network structure of the target detection model provided by the embodiment of the present invention.

[0092] The output of the network contains three parts: the classification of the object, the mask of the object, and the two-dimensional bounding box of the object. The present invention mainly uses the mask result of the object, because the mask directly corresponds to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com