Core for winding, method for producing the same, and electronic component with winding

A manufacturing method and winding technology, which can be applied to inductors with magnetic cores, transformer/inductor components, electrical components, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

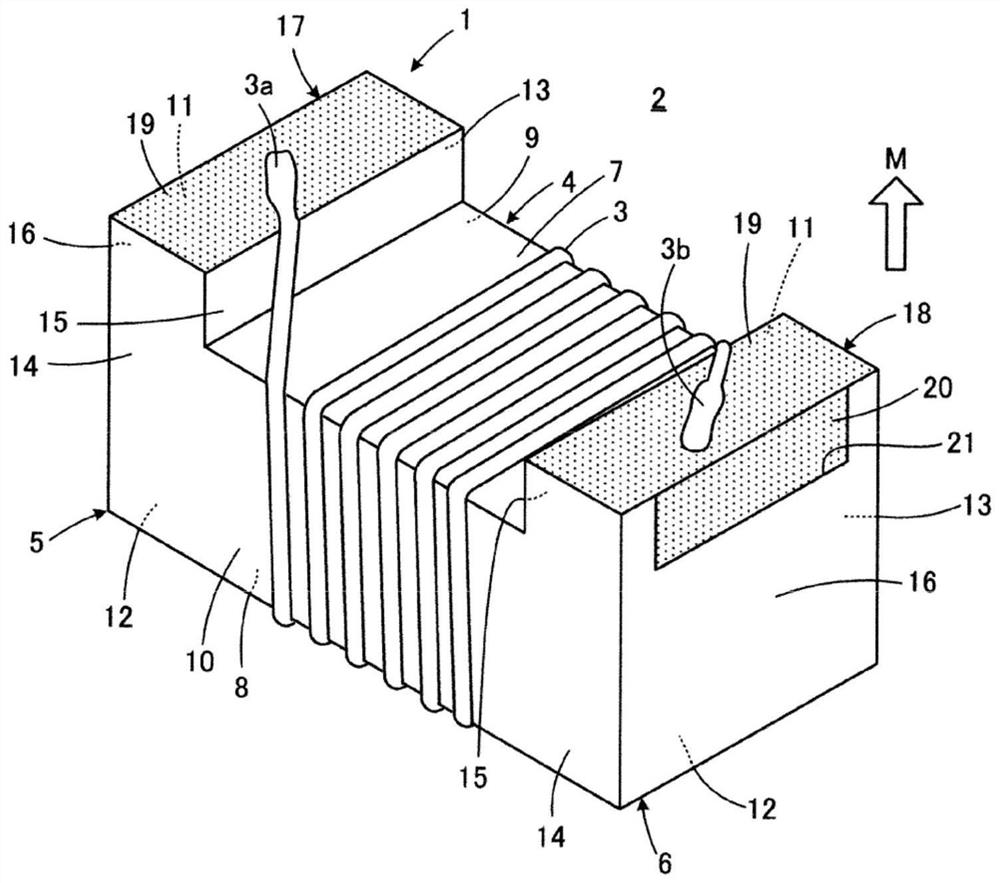

[0068] First, refer to figure 1 , the electronic component 2 with a winding provided with the winding core 1 according to the first embodiment of the present invention will be described. exist figure 1 In , the electronic component 2 with a winding is shown with the bottom surface facing the mounting substrate facing upward. The illustrated electronic component 2 with a winding is, for example, a coil component having a single coil.

[0069] The winding core 1 included in the electronic component 2 with the winding has the winding core 4 on which the winding 3 is arranged, the first flange 5 and the second flange 6, and the first terminal electrode 17 and the second terminal electrode 18. . The core 4 has a longitudinal direction, and the first and second flanges 5 and 6 are respectively provided at first and second ends opposite to each other in the longitudinal direction of the core 4 .

[0070] The winding core 1 is made of a non-conductive material, more specifically, ...

no. 2 approach

[0104] Next, refer to Figure 10 , the winding core 1a according to the second embodiment of the present invention will be described. exist Figure 10 In the following figures, for the Figure 1 to Figure 9 Components corresponding to the shown components are denoted by the same reference signs, and redundant descriptions are omitted.

[0105] In the above-mentioned first embodiment, the winding core part top surface 8 in the winding core body 1 is the same surface as the flange part top surface 12, but in the second embodiment, the characteristic feature is that the winding core body 1a The top surface 8 of the core portion is lower than the top surface 12 of the flange portion, that is, the top surface 8 of the core portion is closer to the mounting substrate than the top surface 12 of the flange portion. If such a structure is adopted, winding 3 (refer to figure 1) can not protrude outward from the flanges 5 and 6 on the core top surface 8 side. Therefore, the winding ...

no. 3 approach

[0110] Next, refer to Figure 12 , the winding core 1b according to the third embodiment of the present invention will be described.

[0111] The third embodiment is first characterized in that the winding core portion top surface 8 is lower than the flange portion top surface 12 in the winding core body 1 b as in the above-mentioned second embodiment. Thus, winding 3 (refer to figure 1 ) can not protrude outward compared with the flanges 5 and 6 on the core top surface 8 side.

[0112] In the above-mentioned second embodiment, the first and second winding core side surfaces 9 and 10 of the winding core 1a are respectively the same as the first and second flange side surfaces 13 and 14, but the third Another characteristic of the embodiment is that the first and second winding core side surfaces 9 and 10 of the winding core 1 b are lower than the first and second flange side surfaces 13 and 14 , respectively. In other words, in the third embodiment, the first and second cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com