Vacuum insulator covering material

A technology of vacuum insulation material and outer skin, which is applied to heat exchange equipment, protects pipelines through heat insulation, heat preservation, etc., can solve the problems of reduced internal volume, deterioration of vacuum holding performance, difficulty in connecting vacuum insulation materials, etc., and achieves easy connection, The effect of preventing internal volume loss and reducing thermal bridge phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the present disclosure will be described in detail with reference to the accompanying drawings.

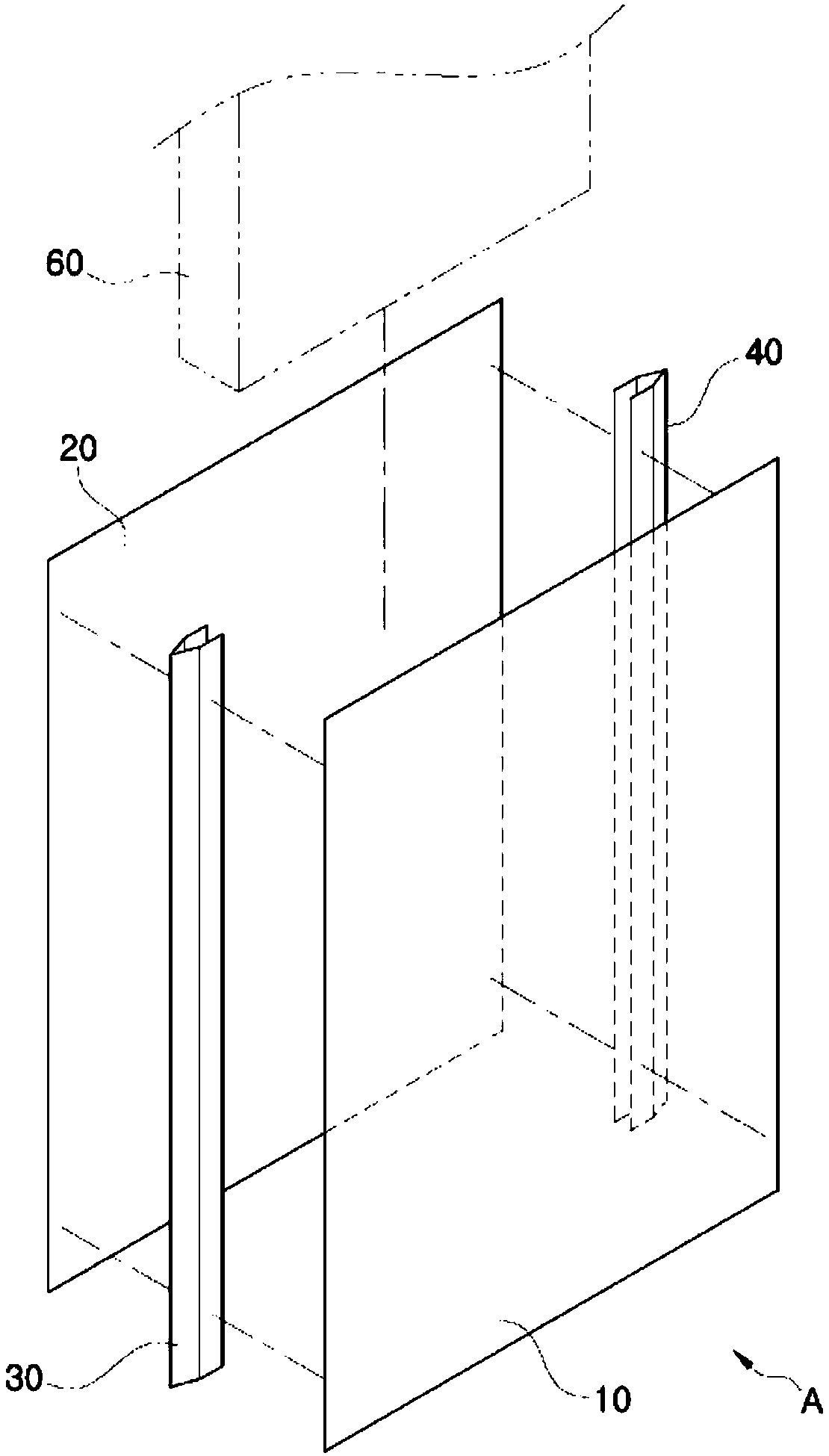

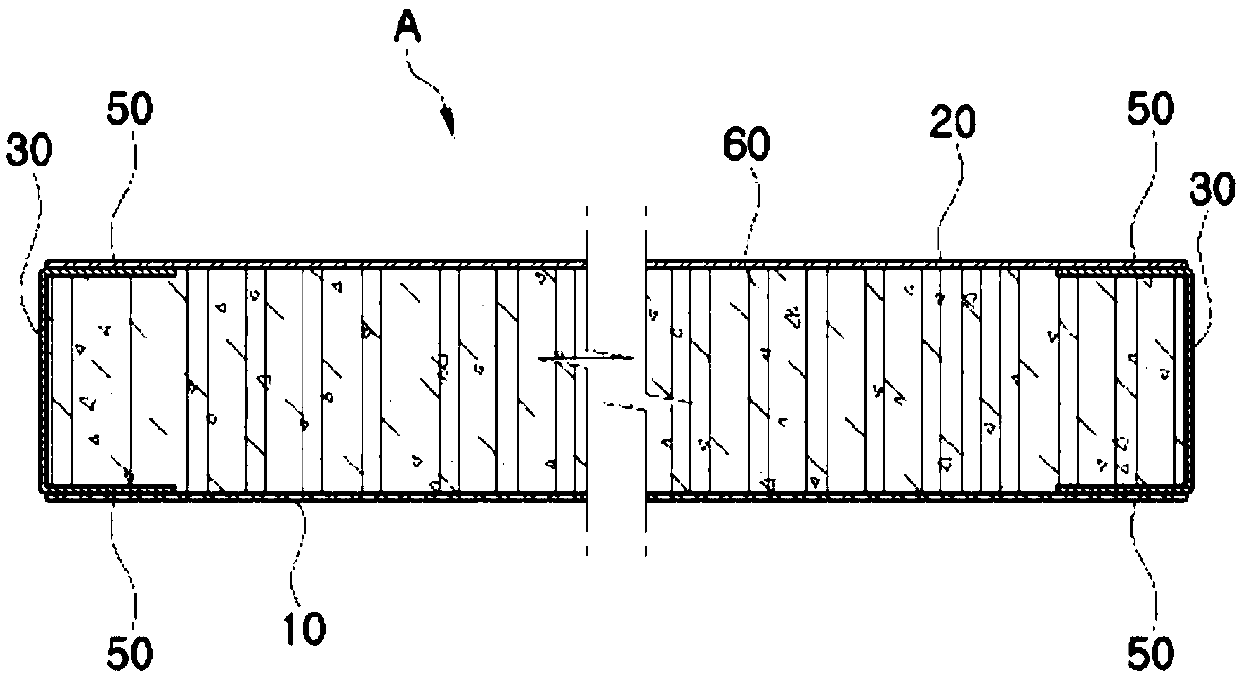

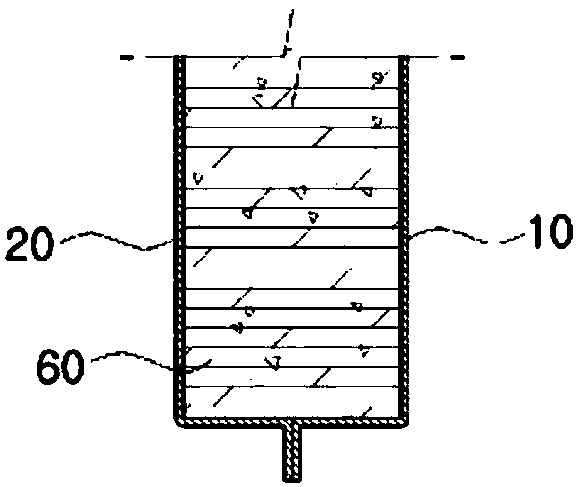

[0030] like figure 1 As shown, the skin material A for a vacuum insulation material according to the present disclosure includes a front surface 10 , a rear surface 20 , a left side surface 30 and a right side surface 40 .

[0031] The front surface 10 forms one surface exposed in front of the skin material A for vacuum insulation material according to the present disclosure.

[0032] One side end inner surface of the front surface 10 is joined to one side end outer surface of the left side surface 30 , and the other side end inner surface of the front surface 10 is joined to one side of the right side surface 40 . The end outer surfaces are engaged so as to provide a seal between the front surface 10 and the left side surface 30 and the right side surface 40 .

[0033] The rear surface 20 forms a surface exposed behind the skin material A for vacuum insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com