Seed distributor of pneumatic conveying type wheat seeding machine

A technology of pneumatic conveying and seed divider, which is applied in the directions of sowing planters, planter parts, and sowing, can solve the problems affecting the uniformity of seeding, poor consistency of displacement, and high seed breakage rate, and achieves guaranteed uniformity, Low cost, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the examples.

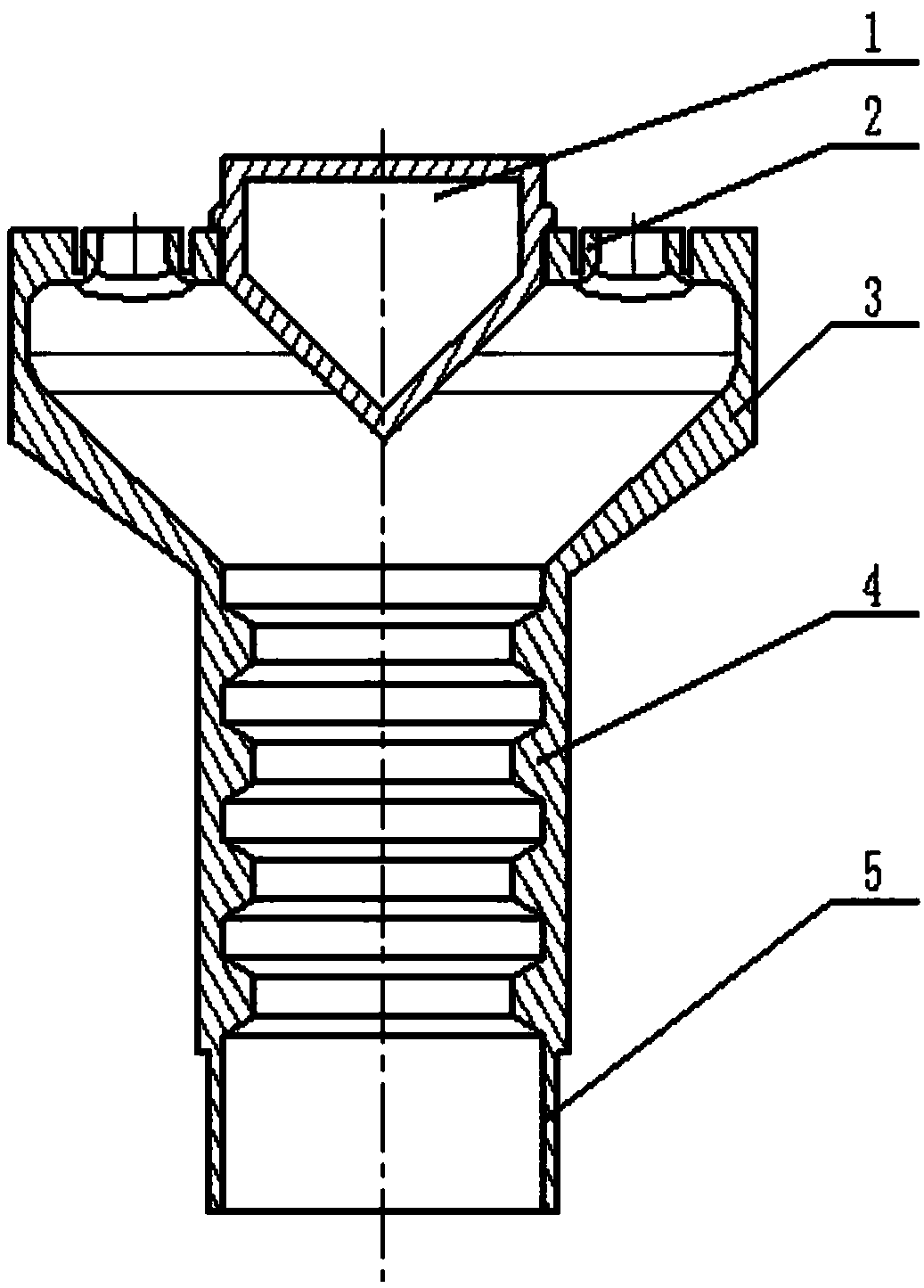

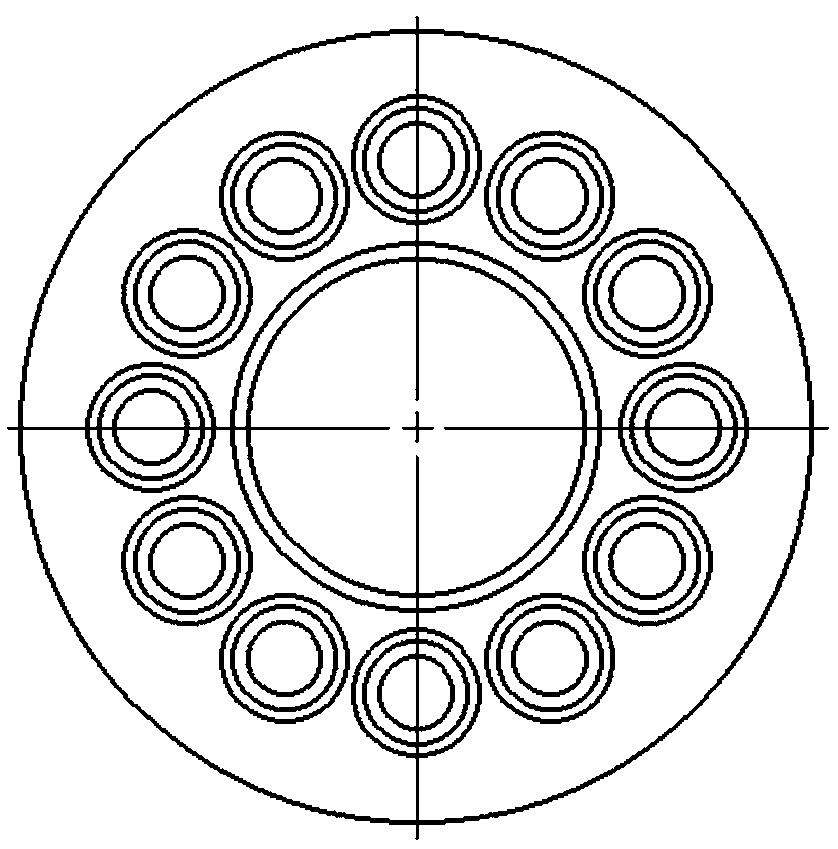

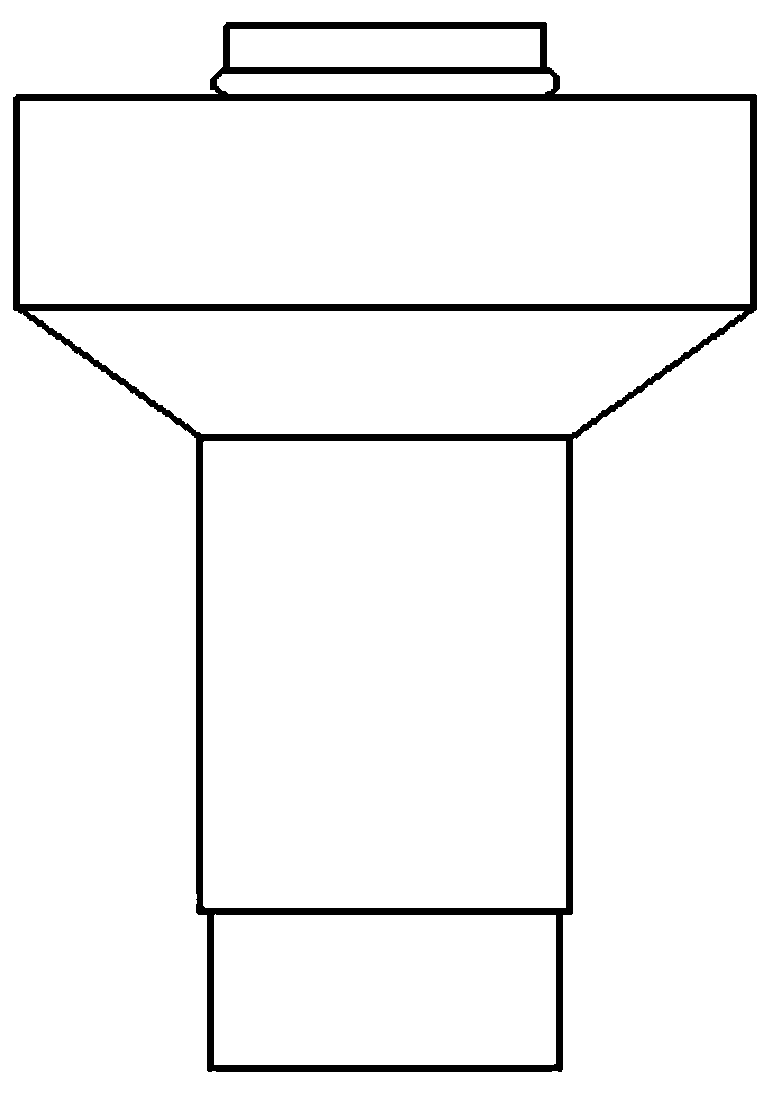

[0027] Such as Figures 1 to 3 As shown, the seed divider of the pneumatic conveying type wheat planter of the present invention includes a seed divider body, a diverter cover 1, a seed guide pipe connection port 2, a seed guide wall 3, a gas-solid mixing wall 4, and a seed transfer pipe connection port 5. The body of the seed divider is an axisymmetric structure, the center of the upper end of the seed divider body is provided with a diverter cover 1, and the upper end surface of the seed divider body is provided with 12 connection ports 2 for seed introduction tubes, And each seed pipe connection port 2 is symmetrically and evenly distributed with the center point of the upper end surface of the seed divider body as the center, and the inside of the seed pipe connection port is a hole where the seed flow flows out, so that the seed flow is distributed to each row; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com