Electrical high-branch shears

An electric technology for high branch shears, applied in the field of pruning shears, can solve the problems of inability to cut high branches, inconvenient use, hidden safety hazards, etc., and achieve the effect of stable work, convenient use and reliable pruning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

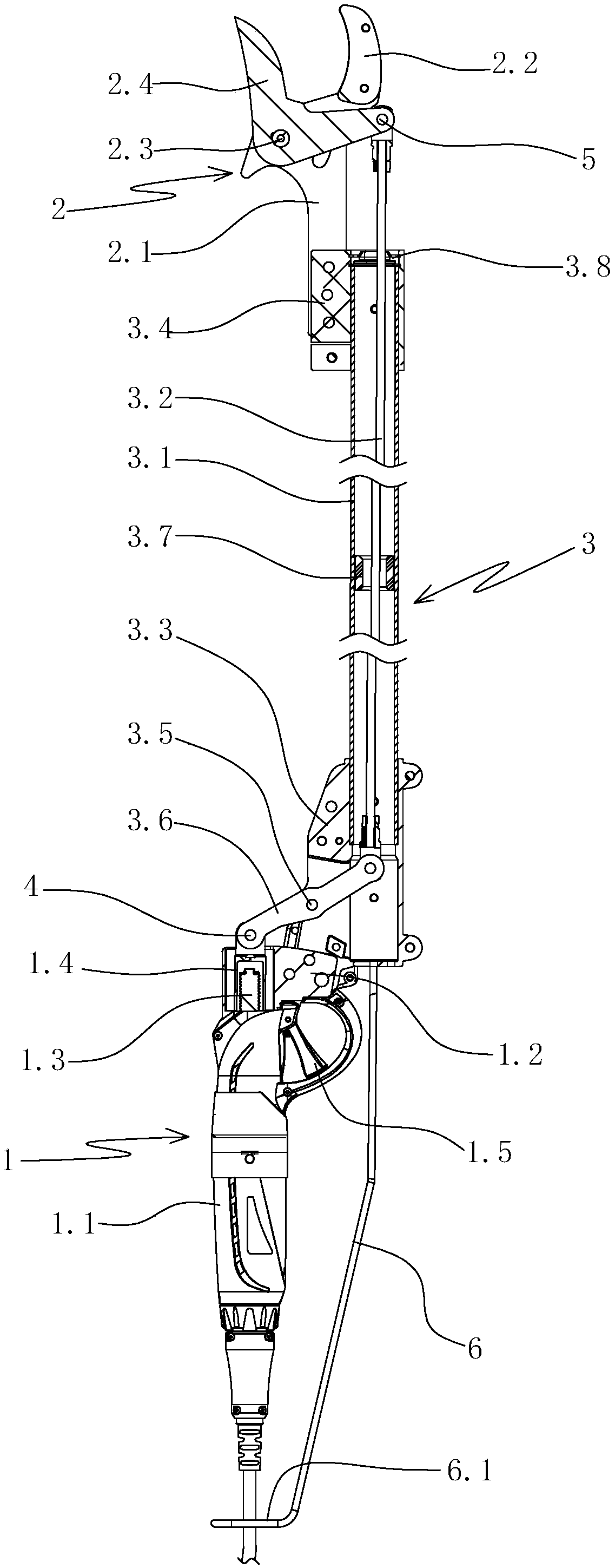

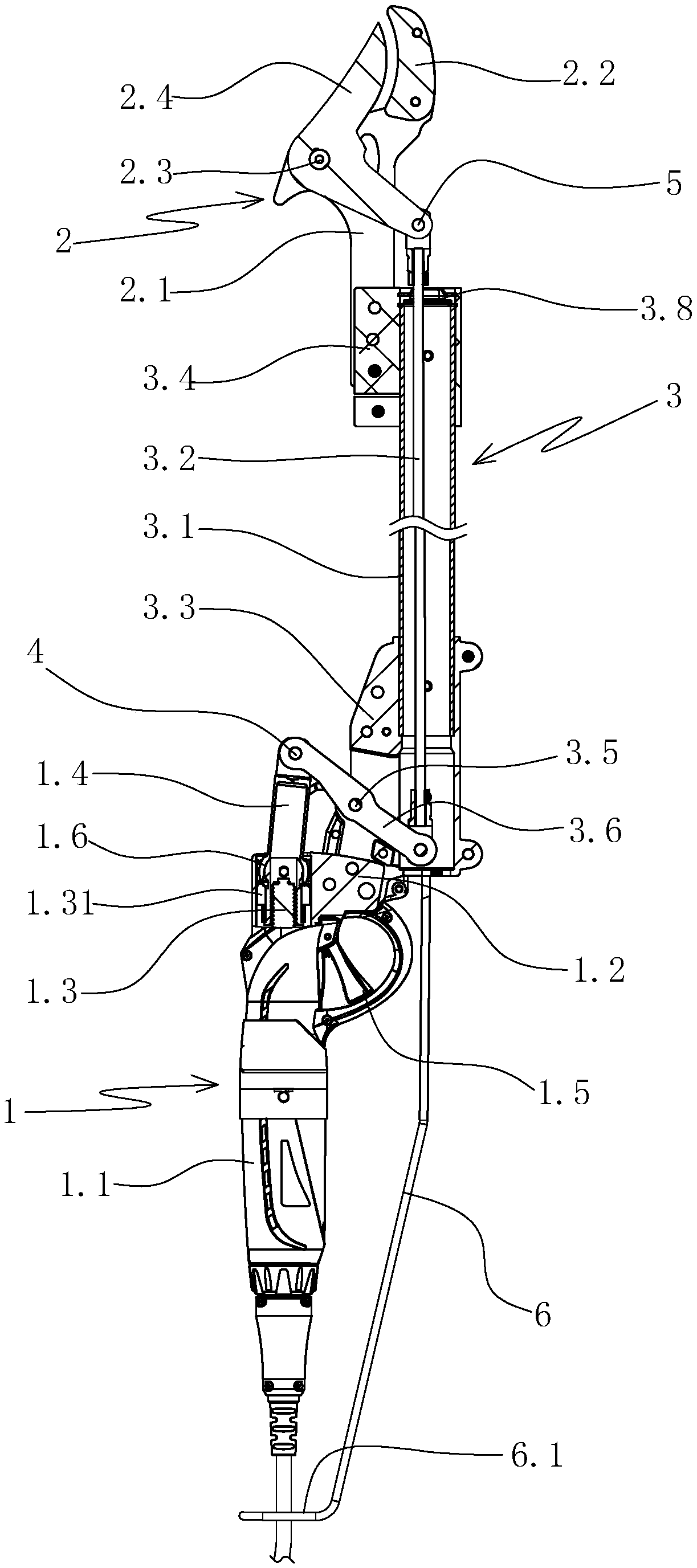

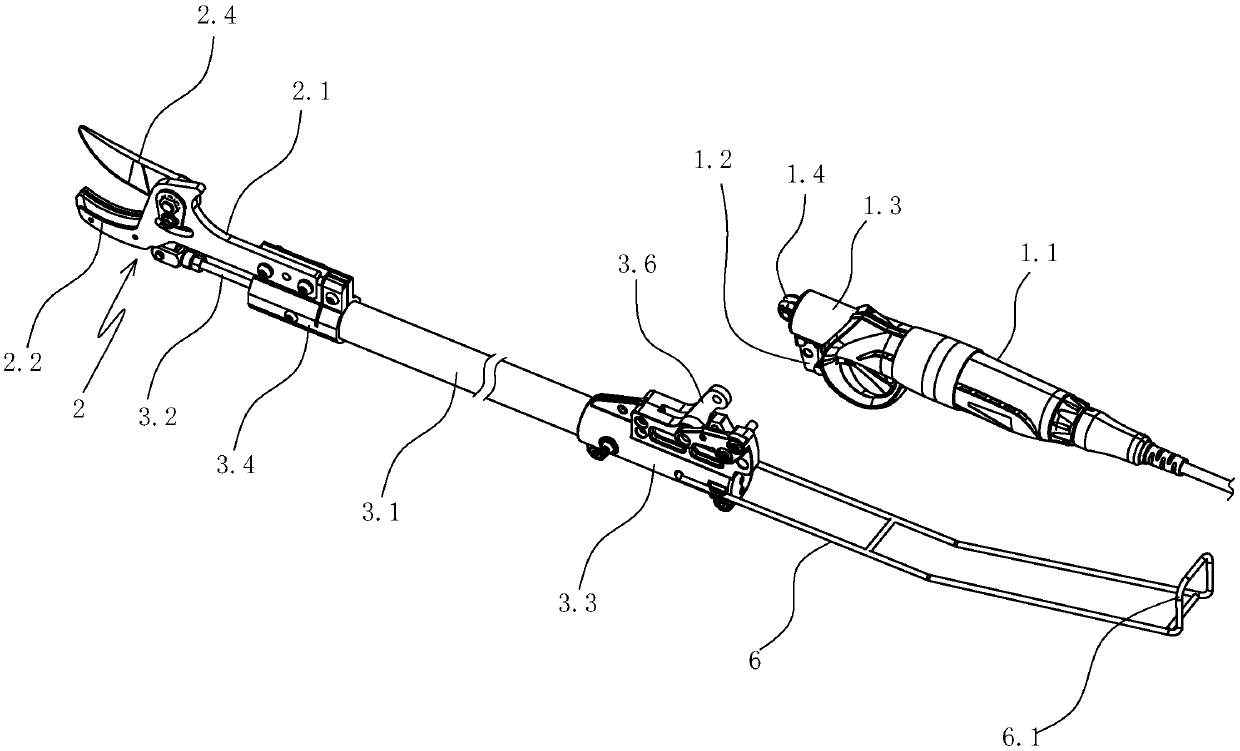

[0037] Specific embodiment one: as figure 1 , figure 2 , image 3 As shown, an electric high branch shear includes a scissors main body 1 , a scissors assembly 2 and a high branch assembly 3 . The scissors main body 1 includes a housing 1.1, a housing mounting portion 1.2 disposed on the housing, an electric push rod 1.3 and a push rod 1.4 disposed on the housing. The end of the push rod 1.31 of the electric push rod is hingedly connected to the first end of the ejector rod or connected through a ball joint. In this embodiment, the end of the push rod 1.31 of the electric push rod is connected to the first end of the ejector rod through Ball joint 1.6 connection.

[0038] The scissors assembly 2 includes a scissors installation part 2.1, a fixed blade 2.2 arranged on the scissors installation part, and a rotating blade 2.4 arranged on the scissors installation part through the rotation of the first pin shaft 2.3.

[0039] The high branch assembly 3 includes a high branch...

specific Embodiment 2

[0047] Specific embodiment two: the specific structure of this embodiment is with reference to specific embodiment one, and its difference is:

[0048] Such as Figure 5 As shown, an electric high branch shear also includes an auxiliary breaking device 7 . The auxiliary breaking device includes an auxiliary pipe 7.1 parallel to the high-branch pipe, a connector 7.2 connecting the auxiliary pipe and the high-branch pipe, an auxiliary rod 7.7 inserted in the auxiliary pipe, a mounting seat 7.3 arranged on the upper end of the auxiliary pipe, and a Mounting plate 7.4 and the breaking bar 7.6 that is arranged on the mounting plate by the 5th bearing pin 7.5 rotation. The breaking rod is L-shaped. The fifth pin shaft is coaxial or parallel to the first pin shaft, and the fifth pin shaft is located at the bending part of the broken rod. The lower end of the auxiliary rod passes through the lower end of the auxiliary pipe and is positioned at the outside of the auxiliary pipe. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com