Soldering system

A technology of soldering and soldering machines, applied in welding equipment, auxiliary devices, metal processing, etc., can solve problems such as equipment damage, and achieve the effect of information identification and avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

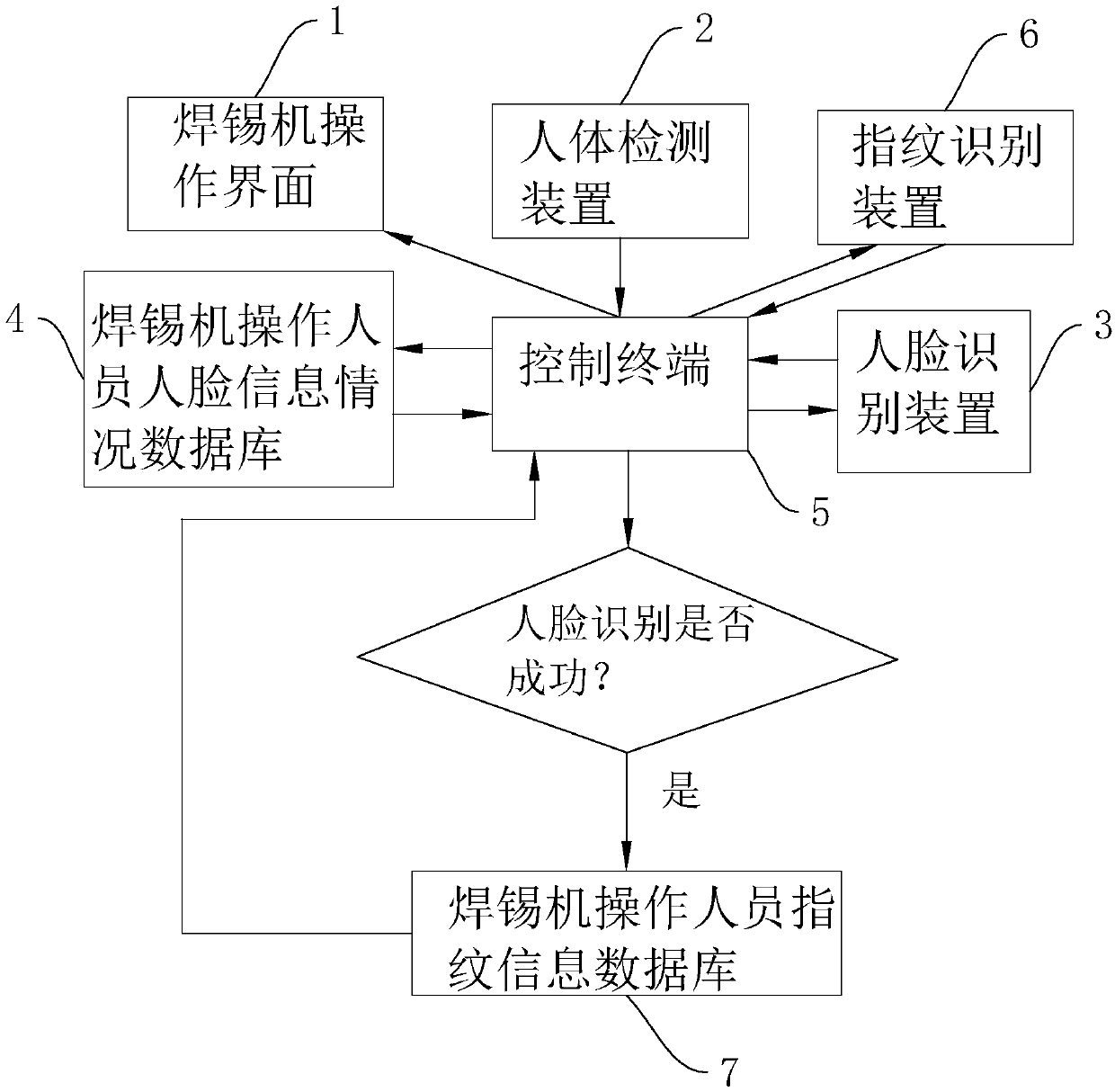

[0034] refer to figure 1 , is a soldering system disclosed in the present invention, including a soldering machine operation interface 1, a human body detection device 2, a face recognition device 3, and a soldering machine operator who stores the number of the soldering machine and the face information of the corresponding numbered soldering machine operator Face information database 4, control terminal 5, wherein the human body detection device 2 is preferably a pyroelectric infrared sensor, and the control terminal 5 is preferably a central processing unit.

[0035] The control terminal 5 detects whether there are people around through the human body detection device 2, and in the case of people, the number of the soldering machine is used as the query object to query the face information of the soldering machine operator in the database 4 of the face info...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com