A socket connector capable of realizing personnel protection inside the equipment

A technology for socket connectors and personnel, which is applied in the direction of two-part connection devices, connections, parts of connection devices, etc., can solve problems such as not being able to meet the diverse needs of customers, and achieve the effect of preventing product scrapping and meeting diverse needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

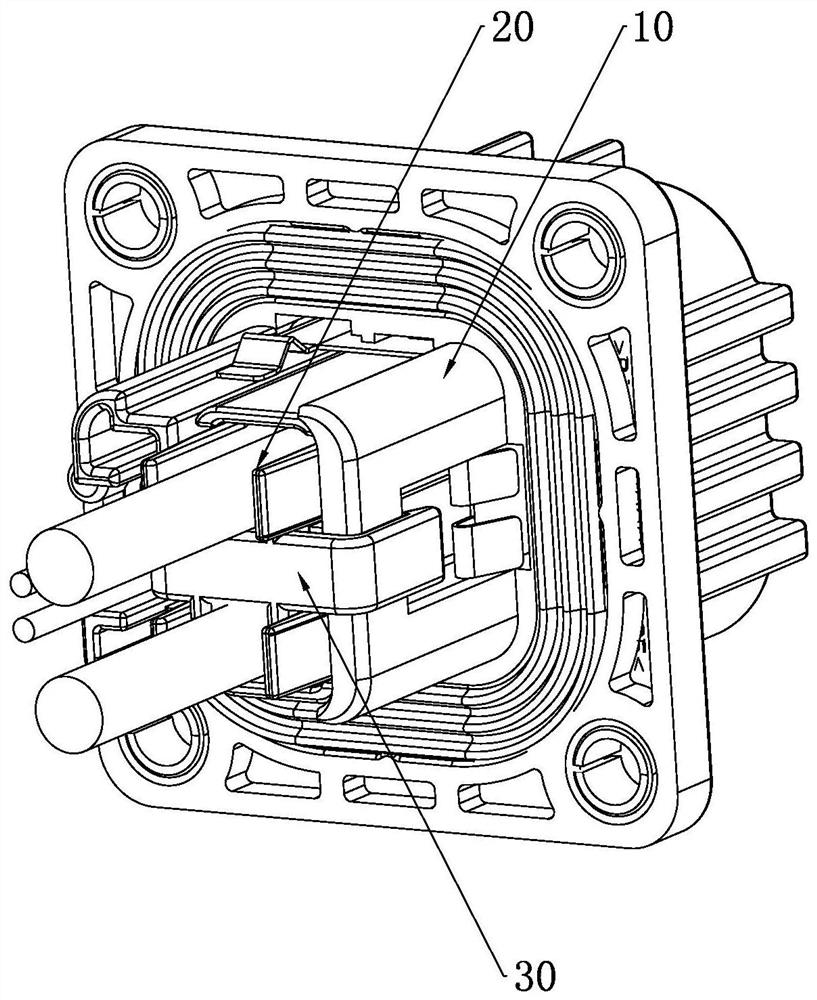

[0031] see figure 1 , is an embodiment of the socket connector of the present invention that can realize personnel protection inside the equipment. In this embodiment, the position where the pin contact is located is defined as "front", and the position where the cable is located is defined as "rear". This embodiment includes an outer shell 10 , an insulator cable component 20 detachably connected to the outer shell, and a buckle 30 detachably connected to the outer shell and used for secondary locking of the insulator cable component.

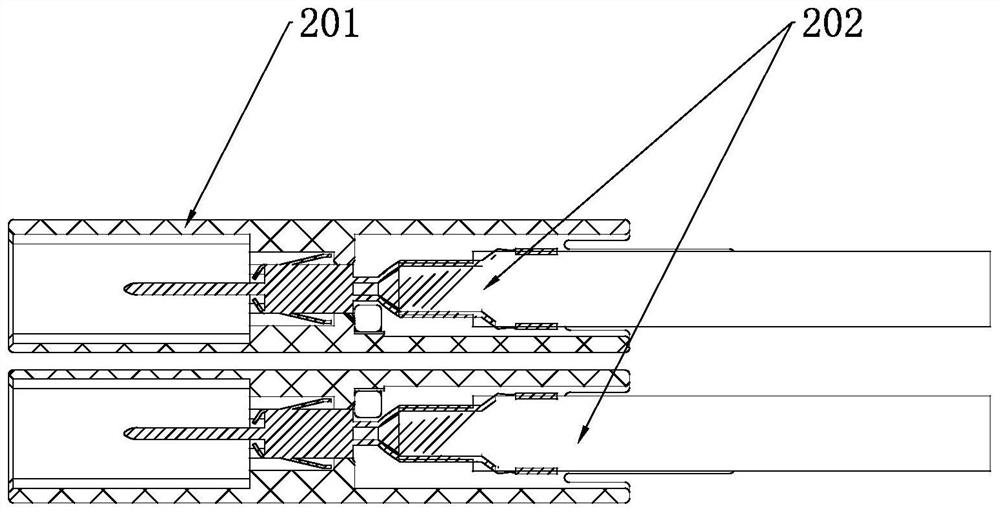

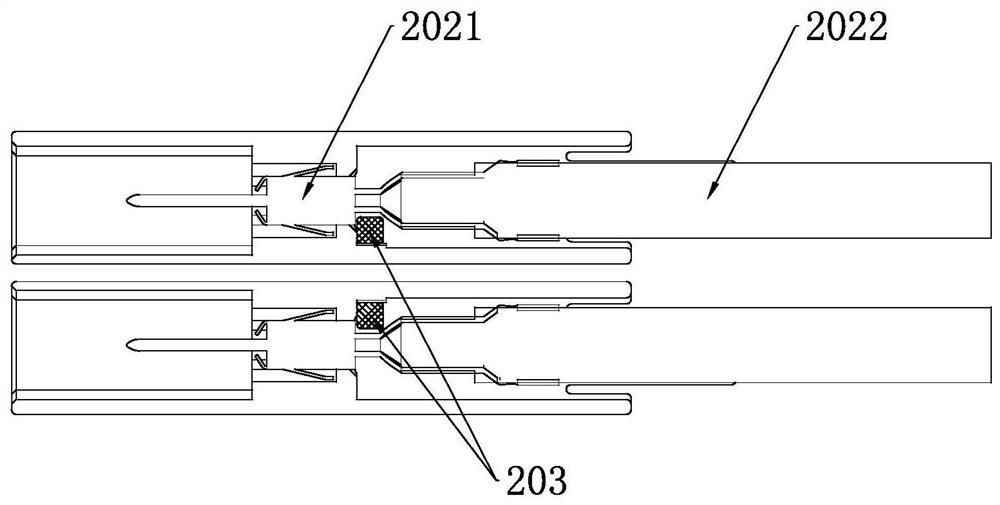

[0032] see figure 2 and Figure 3A The insulator cable part 20 includes an insulator 201, a pin cable part 202 installed in the insulator, a lock hook 2011 with a guiding slope is arranged on the insulator 201, and the insulator located on the rear side of the lock hook ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com