High-speed thermal expansion driver

A drive and thermal expansion technology, which is applied in the direction of machines/engines, machine operation methods, lighting and heating equipment, etc., can solve problems such as slow cooling speed, insufficient drive response speed, and slow response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

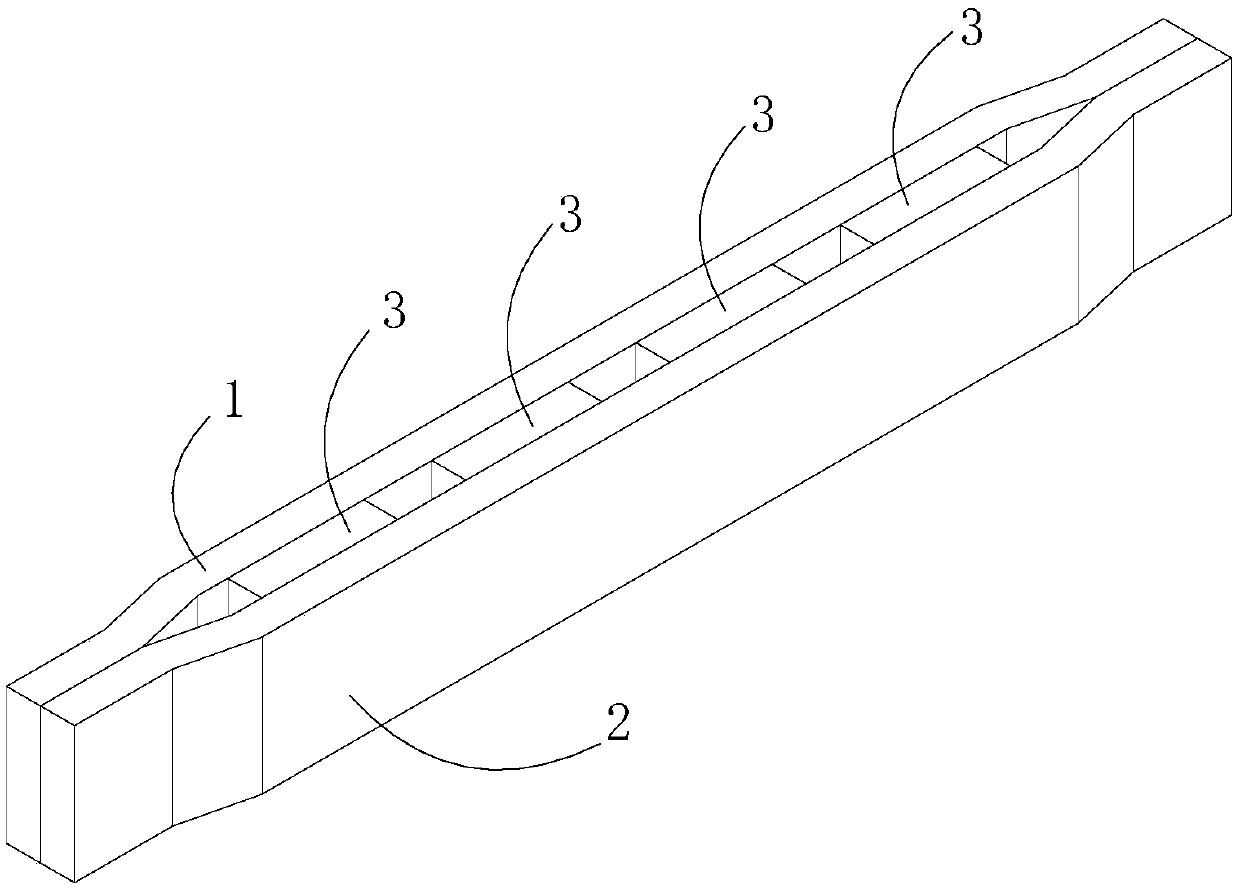

[0008] Reference figure 1 , This high-speed thermal expansion driver includes: a first sheet and a second sheet, characterized in that it also includes a refrigeration sheet, wherein: the first sheet and the second sheet are made of high thermal expansion coefficient materials, and are a middle outward The arched elongated sheet structure; the bottom surfaces of the unarched portions of the first sheet and the second sheet are welded together; the cooling sheet is a semiconductor refrigerator composed of a P-type semiconductor element and an N-type semiconductor element. The surfaces are respectively the cooling electrode and the heating electrode, which are installed between the first sheet and the second sheet, and the cooling electrode and the heating electrode are respectively adhered to the first sheet and the second sheet by an adhesive with good thermal conductivity. And the polarities of the two adjacent refrigeration fins are opposite.

[0009] When in use, one or both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com