Novel cam-connecting rod mechanism of rapid forming machine

A technology of cam connecting rod and forming machine, which is applied in the direction of electromechanical device, mechanical equipment, control mechanical energy, etc., can solve the problems of low efficiency of up and down movement of sealed box, low production efficiency of forming machine, etc., and achieve the effect of prolonging life and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

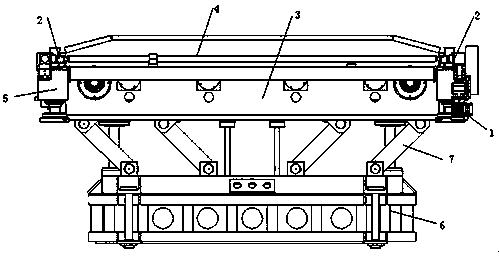

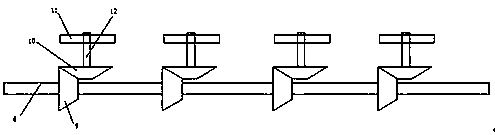

[0017] Embodiment: When in use, the drive motor 1 drives the input shaft in the gear reduction box 5 to rotate through two cross universal joints 2 and the transmission rod 4, and the output shaft in the gear reduction box 5 drives the drive shaft 8 to rotate, and the drive shaft 8 drives the first bevel gear 9 to rotate, the first bevel gear 9 and the second bevel gear 10 rotate, the second bevel gear 10 drives the rotating shaft 12 to rotate, the rotating shaft 12 drives the eccentric wheel 11 to rotate, and the eccentric wheel 11 drives the cam connection The rod mechanism 7 moves up and down, thereby 1 drives the sealing box 6 to move up and down, which improves the production efficiency of the molding machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com