Production method of light-emitting cable

A production method and technology of luminous wires, applied in cables, optics, light guides, etc., can solve the problems of short luminous duration, insufficient luminous time, and insufficient luminous intensity, so as to improve luminous intensity and luminous time, and ensure the design size The effect of requiring, enhancing the ability to receive light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

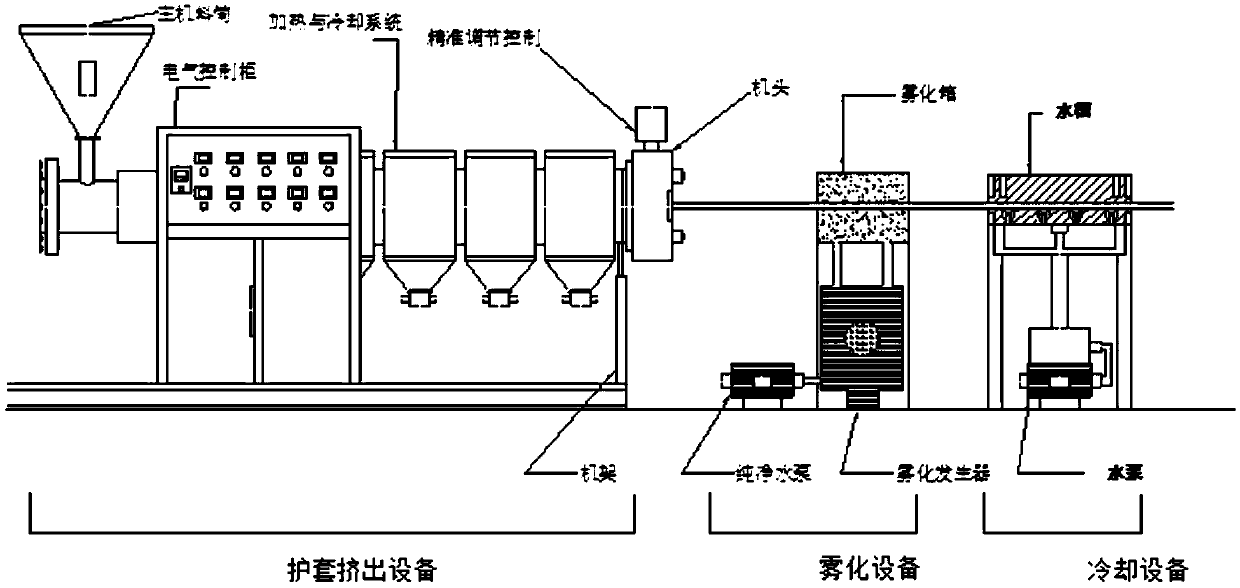

Image

Examples

Embodiment 1

[0017] (1) Wire drawing and annealing the round metal wires to be twisted separately to make conductors, coat the conductors with an insulating layer, and extrude a water-blocking tape outside the insulating layer to form an insulated wire core, and multiple insulated wire cores are twisted with each other to form an insulated wire The core group: wrapping the tape on the outer periphery of the insulated wire core group and filling the gaps between the insulated wire cores.

[0018] (2) Prepare a flame-retardant layer, heat the flame-retardant material to melt, and then cool to obtain a flame-retardant layer, and wrap the prepared flame-retardant layer on the outer periphery of the tape.

[0019] (3) Prepare the shielding layer: equip the shielding layer material, and wrap the shielding layer material on the outside of the flame retardant layer by extrusion molding.

[0020] (4) Prepare the inner liner, and wrap the inner liner around the outer periphery of the shielding layer...

Embodiment 2

[0025] Same as Example 1, except that the diameter of atomized particles is 0.45 μm, and the concentration of atomized particles is 600 / L.

Embodiment 3

[0027] Same as Example 1, except that the diameter of atomized particles is 0.25 μm, and the concentration of atomized particles is 900 / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com