A special milling fixture for high-voltage contactor moving contact piece

A technology of high-voltage contactors and moving contacts, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increased difficulty in processing components, difficult clamping and processing, etc., to shorten the development cycle and reduce The effects of being pinched and ensuring the design size requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention are further described below, but the claimed scope is not limited to the description.

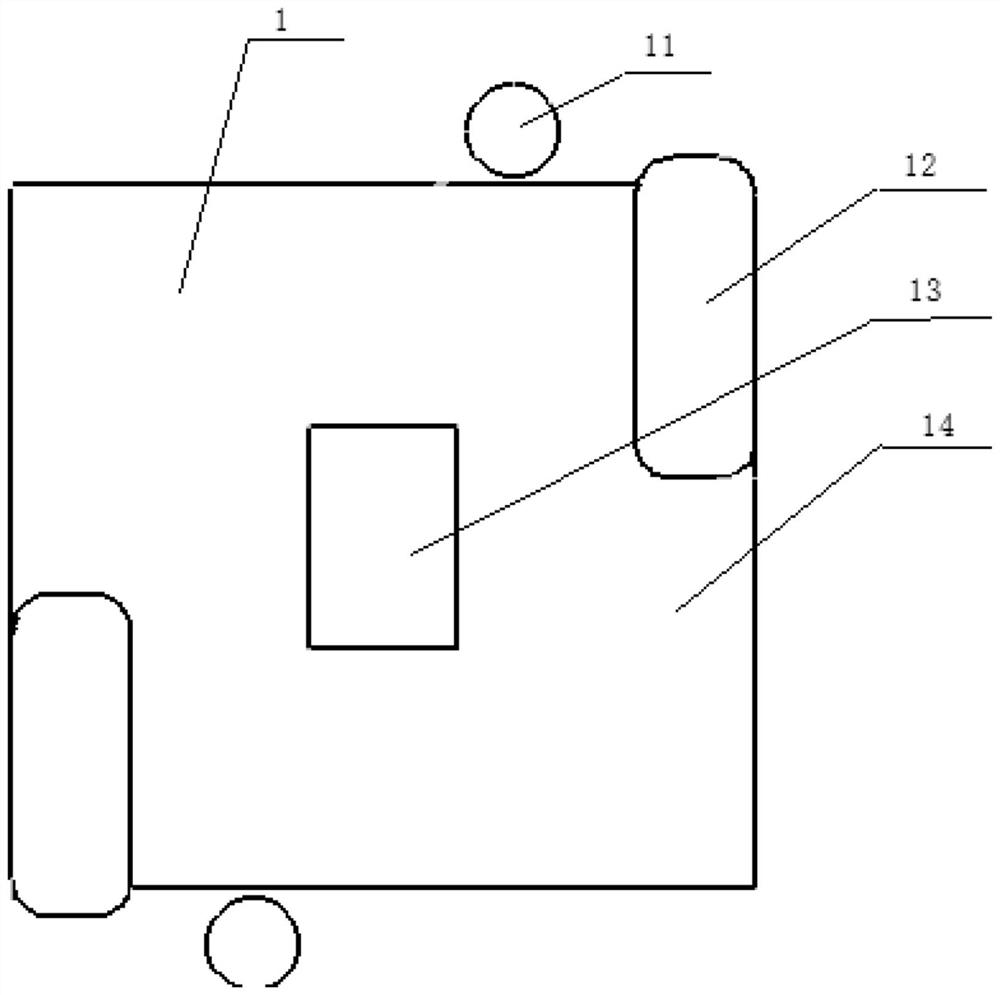

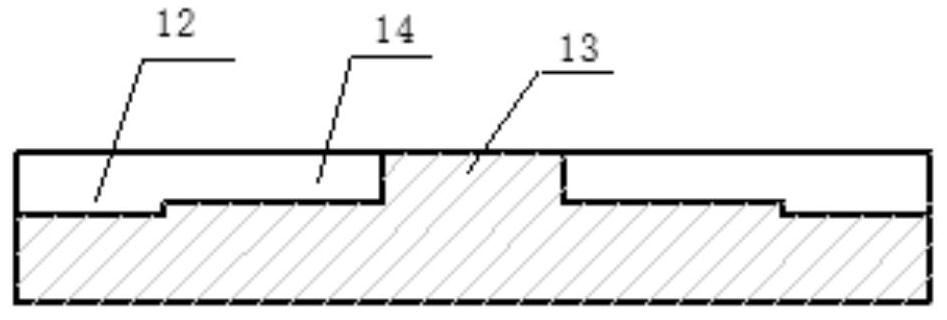

[0023] A special milling fixture for a moving contact piece of a high-voltage contactor, comprising a first fixture 1 and a second fixture 2; the first fixture 1 and the second fixture 2 are grooves machined on a flat plate;

[0024] The first fixture 1 includes a positioning groove 14, the positioning groove 14 is a square groove, the center of the first fixture 1 is machined with a positioning table 13, and two diagonal corners of the first fixture 1 are respectively machined with a reserved groove 12. The outer end of a fixture 1 is oppositely machined with two fixing plate mounting holes 11 adjacent to the two reserved grooves 12;

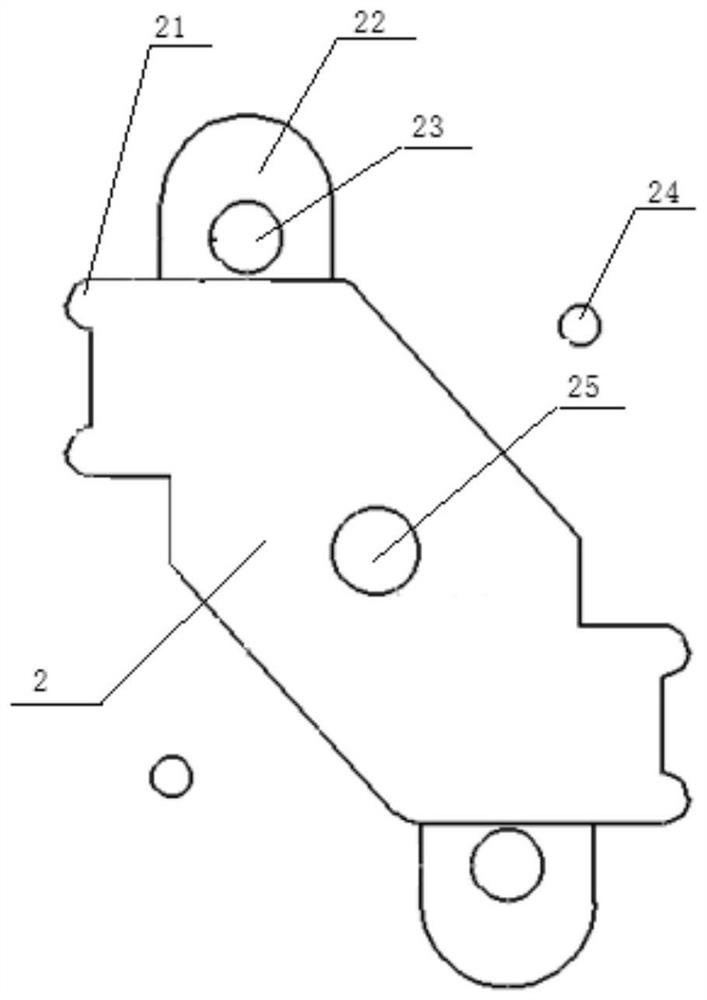

[0025] The second fixture 2 is a zigzag groove with the same shape as the contact piece, the center of the second fixture 2 is processed with a central positioning column 25, and the two ends of the zig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com