Device and method for assembling tension spring

An assembly device and tension spring technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency, affecting assembly accuracy, and inaccurate assembly, so as to ensure accuracy and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

[0030] The tension spring assembling device disclosed by the present invention is used for assembling the tension spring in the heel lancing device, and can improve the assembly efficiency and accuracy of the tension spring.

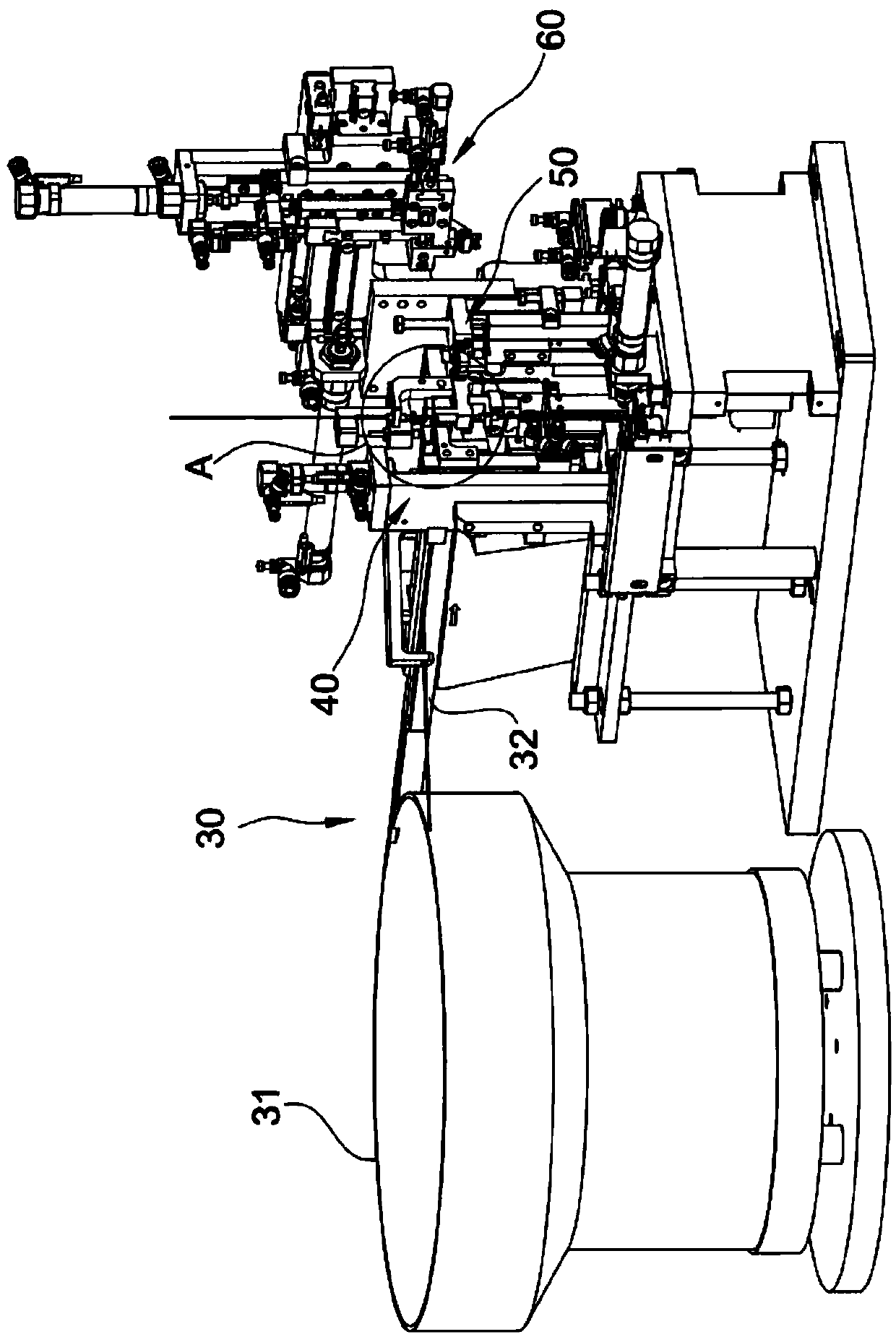

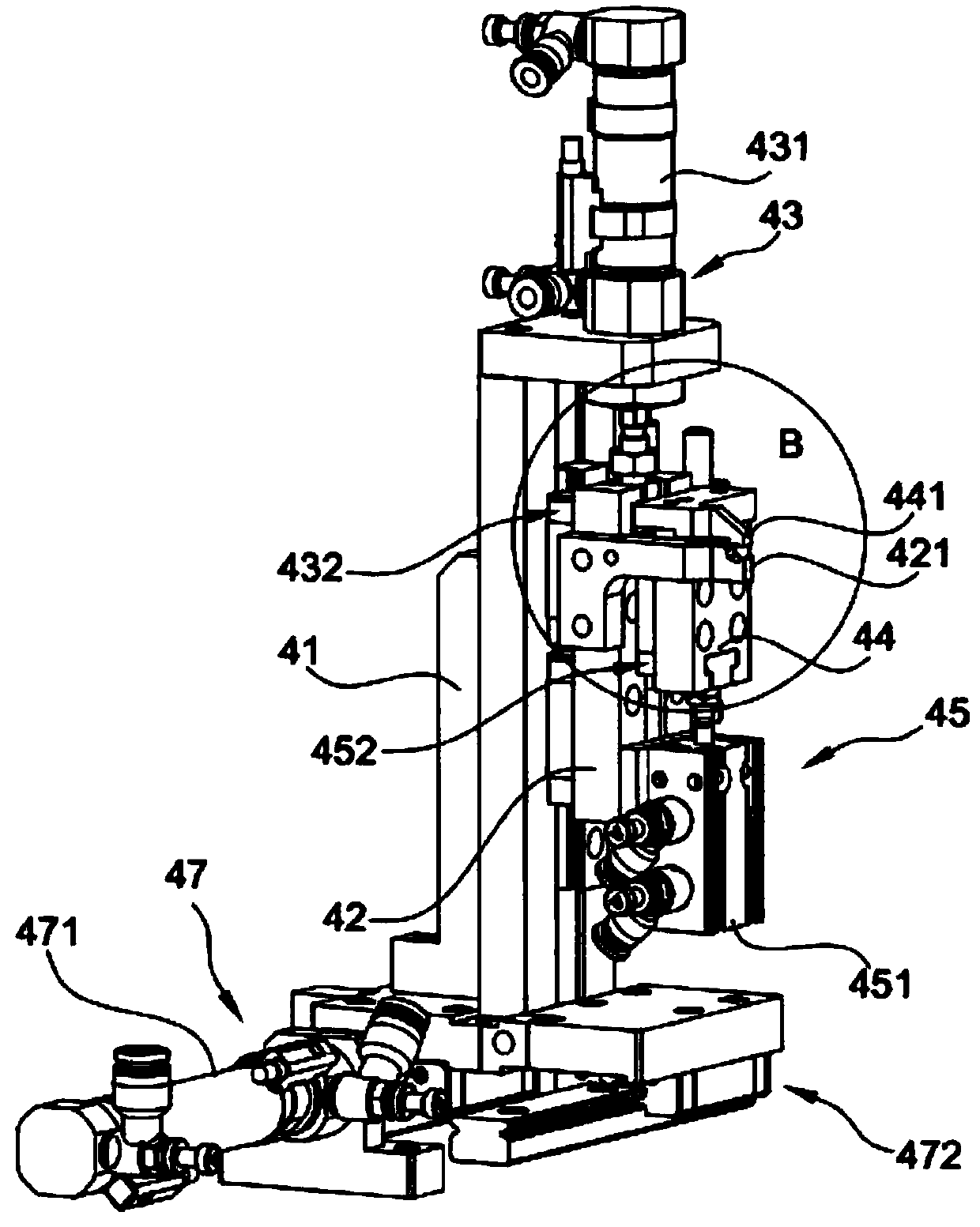

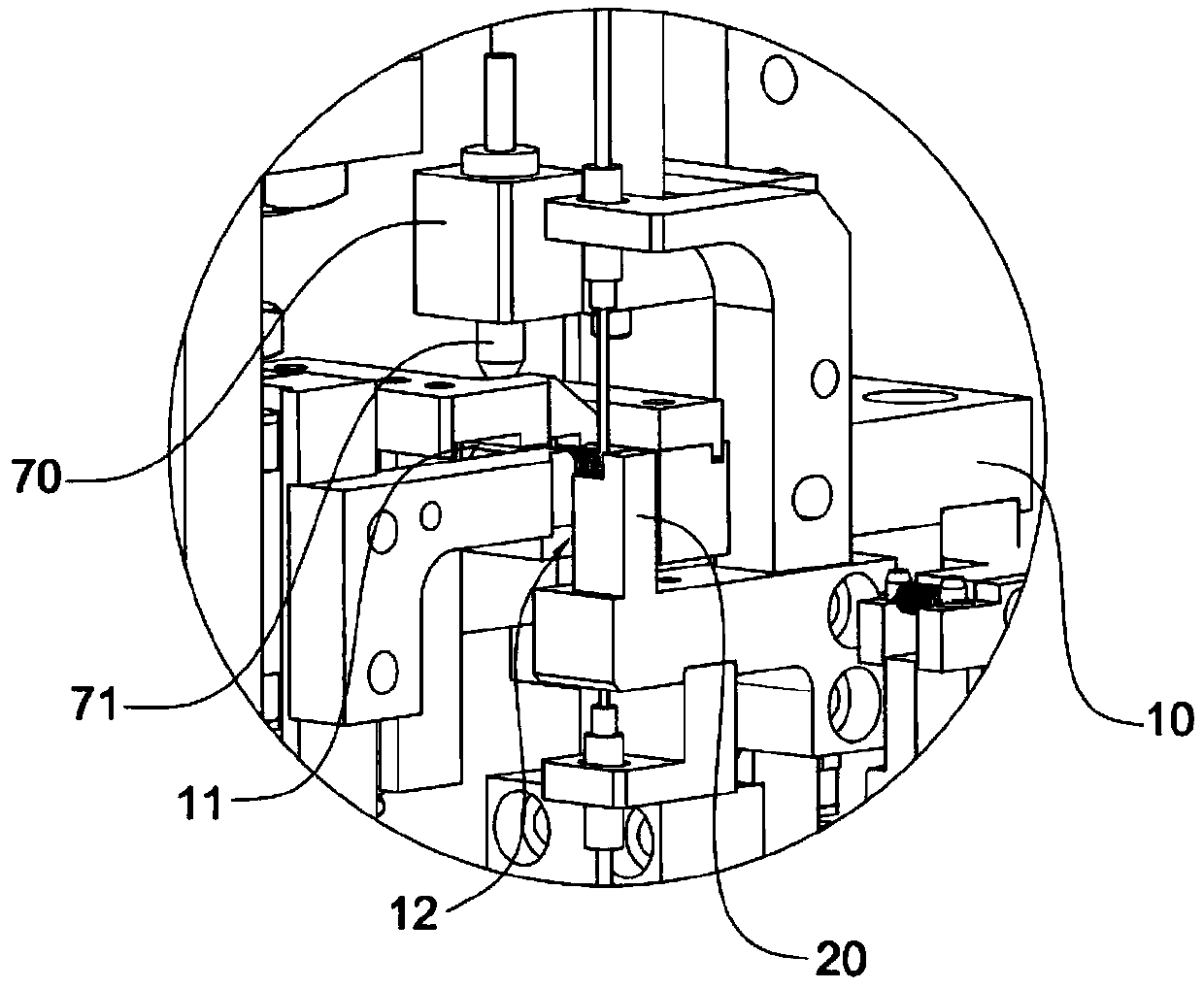

[0031] like figure 1 As shown, a tension spring assembly device disclosed in the present invention includes a first supporting member 10, a second supporting member 20, a tension spring feeding mechanism 30, a tension spring clamping mechanism 40, a tension spring positioning mechanism 50 and a tension spring Spring transplanting mechanism 60. Wherein, the first supporting member 10 is provided with a flow channel 11 for the extension spring to pass through, and the flow channel 11 has an inlet and an outlet; the second supporting member 20 is arranged near the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com