Ink-jet printer for machining of lithium batteries

A lithium battery and inkjet printer technology, which is applied in typewriters, power transmission devices, printing, etc., can solve the problems of limited use and non-adjustable structure, and achieve high inkjet efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

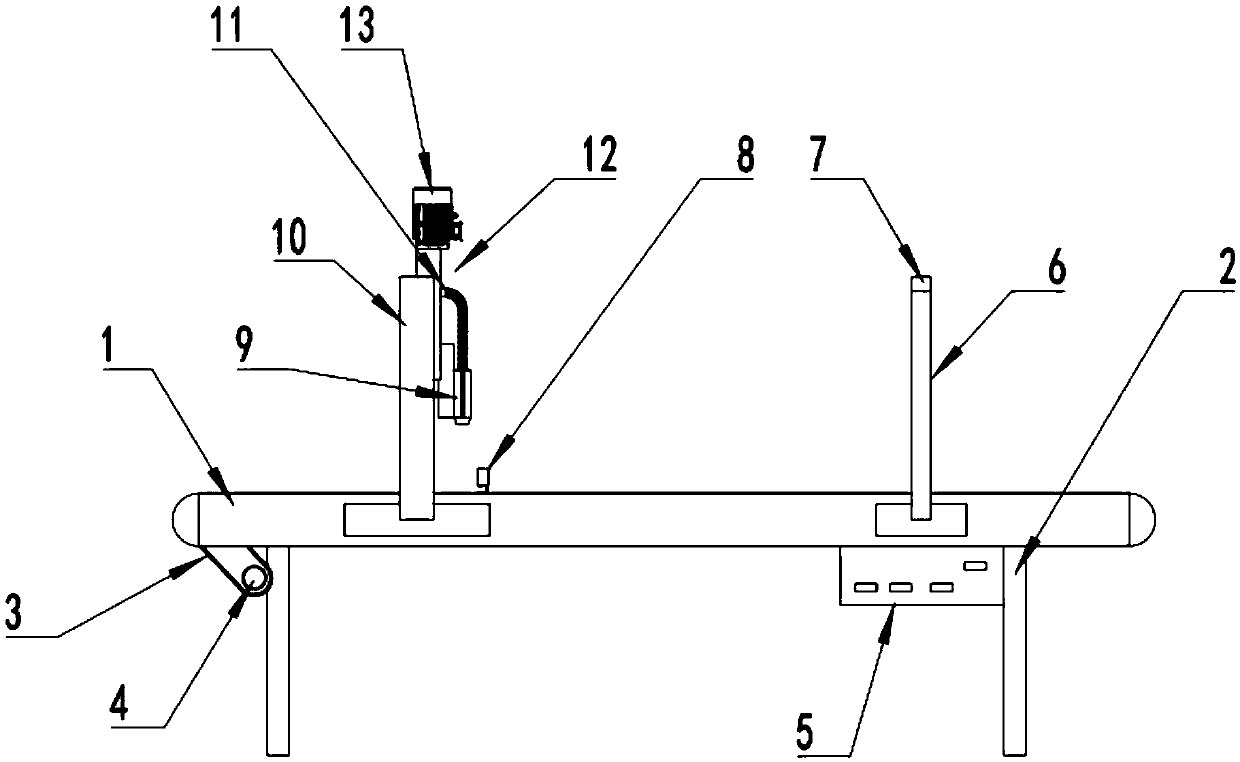

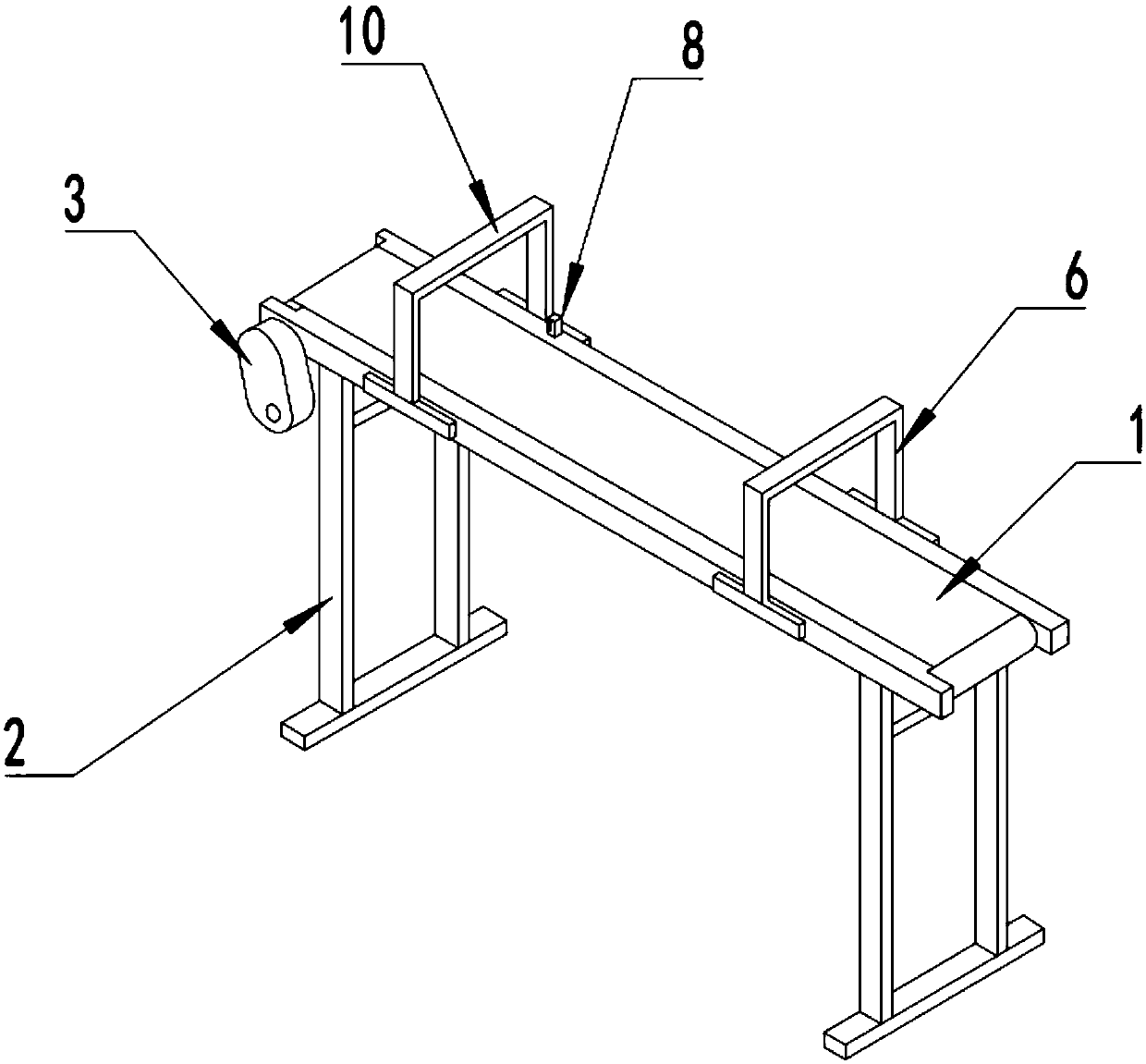

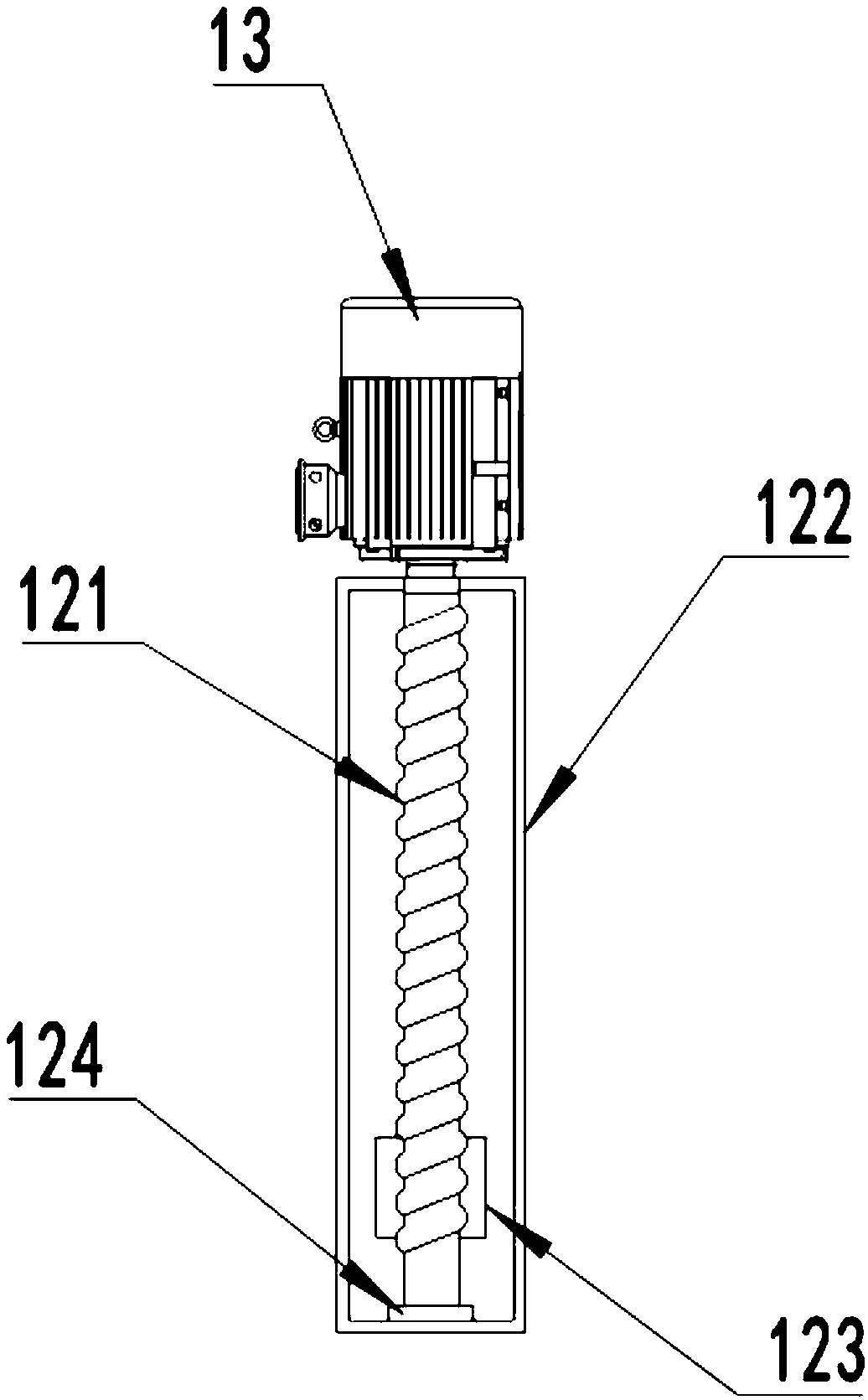

[0023] see Figure 1~2 , in an embodiment of the present invention, an inkjet printer for lithium battery processing includes a conveyor belt 1, a conveyor belt bracket 2, an industrial computer 5 and an inkjet printer head 9, the conveyor belt 1 is installed on the conveyor belt bracket 2, and the conveyor belt 1 consists of The motor and the synchronous belt drive the operation, and the synchronous belt is packaged in the belt box 3. Along the moving direction of the conveyor belt 1, the gantry I6 and the gantry II10 are fixed on the conveyor belt support 2 in sequence, and the gantry I6 is installed with a lithium battery for measuring lithium. Measuring light curtain 7 of battery length and height, here, measuring light curtain 7 is actually a kind of volume measuring light curtain widely used in logistics industry, but in this embodiment, need not measure the volume of lithium battery, only need Just measure its length and height. Measuring its height helps to adjust the ...

Embodiment 2

[0027] see Figure 5 , in the embodiment of the present invention, a kind of inkjet printer for lithium battery processing, on the basis of the above-mentioned embodiment, since in actual application, the quality of the inkjet needs to be detected after the inkjet is completed, while in the prior art, the inkjet Code quality detection is mostly a separate process, which is integrated in this embodiment, specifically:

[0028] Gantry III14 is also fixed on the conveyor belt support 2, and Gantry I6, Gantry II10 and Gantry III14 are arranged sequentially along the moving direction of the conveyor belt 1, and a coding detection device 15 is installed on the Gantry III14, and the coding detection The mode or structure of the device 15 is disclosed in patents such as CN204990346U and CN106874908A, and no redundant description is made here. The code-spraying detection device 15 is electrically connected to the industrial computer 5 . In addition, a rejecting device is installed on ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap