Overhead dual-drive device used for passenger cableway of coal mine

A dual-drive, ropeway technology, used in cable railways, motor vehicles, transportation and packaging, etc., can solve the problems of large amount of foundation construction, large space occupation, and high layout cost, and achieves reduction of renovation amount, reduction of construction costs, and increase of The effect of large enclosing corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

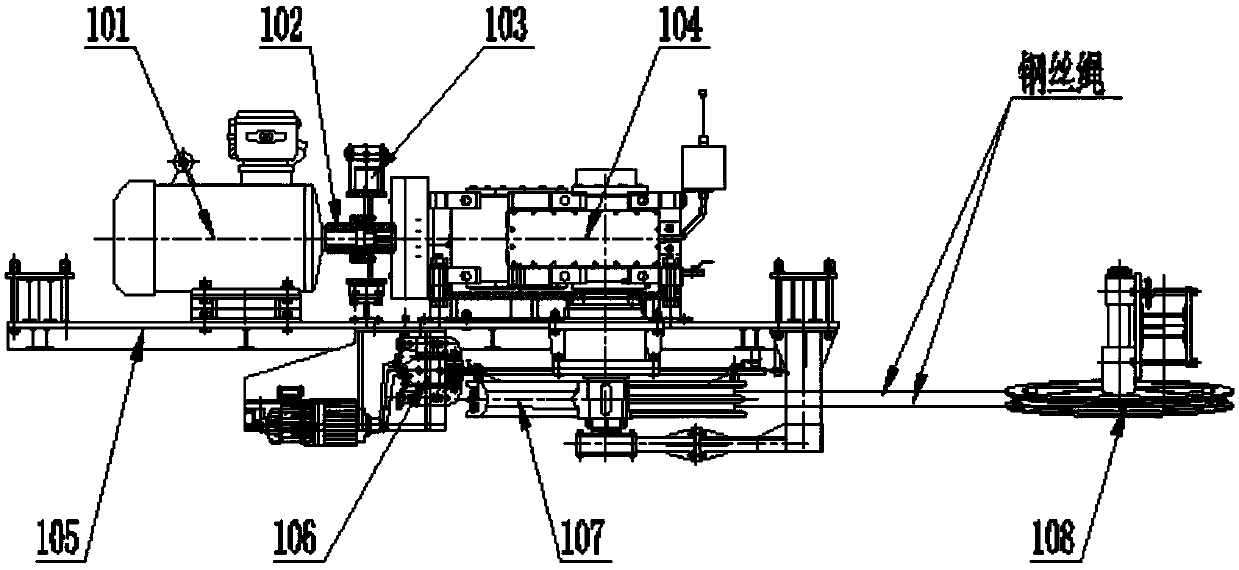

[0016] Such as figure 1 As shown, an overhead double drive device for a passenger cableway in a coal mine includes a main drive part and an auxiliary drive part, both of which are arranged in an independent overhead manner; the main drive part includes a motor 101 connected to a main frame 105, Coupling 102, working brake 103, speed reducer 104, safety brake 106 and double-groove main drive wheel 107, described motor 101 is connected shaft coupling 102, and coupling 102 is respectively connected working brake 103 and speed reducer 104, and speed reducer 104 connects double groove main driving wheel 107, and connects safety brake 106 on the double groove main driving wheel 107; Described auxiliary drive part is the single groove auxiliary driving wheel 108 that is connected with double groove main driving wheel 107 by steel wire rope.

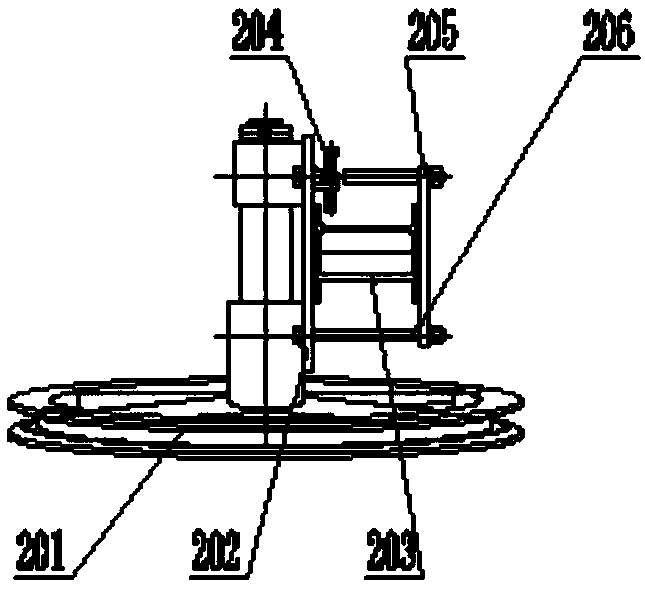

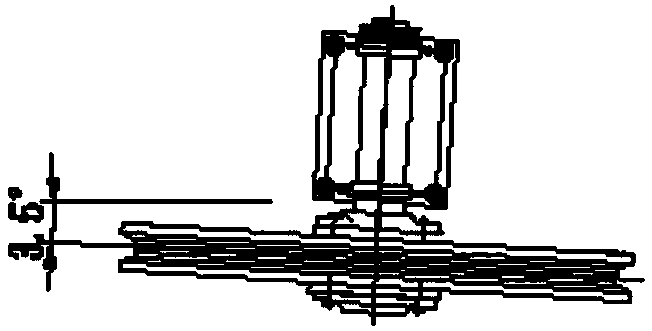

[0017] Such as Figure 2-Figure 3 As shown, the single-groove secondary driving wheel 108 includes a driving secondary wheel 201, a mounting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com