A method for preparing mannuronic acid monomers by degrading polymannuronic acid with sulfuric acid

A technology of polymannuronic acid and mannuronic acid, which is applied in the field of sulfuric acid degradation of polymannuronic acid to prepare mannuronic acid monomer, can solve the problems of high price, achieve short time-consuming, high practicability, and degradation Conditions and effects of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing mannuronic acid monomers by degrading polymannuronic acid with sulfuric acid, comprising the following steps:

[0048] (1) Degradation of polymannuronic acid

[0049] Weigh 6g of polymannuronic acid sodium in a three-necked bottle, add 300mL concentration of 2mol / L sulfuric acid solution to prepare a 20g / L polymannuronic acid sulfuric acid degradation system, and stir at room temperature to make polymannuronic acid fully Dissolve; then stir in a water bath at 80°C for 4 hours; after the reaction, add anhydrous calcium carbonate powder to remove sulfate groups, filter, adjust the pH of the filtrate to neutral with NaOH solution, concentrate to obtain the oligosaccharide mixture; freeze-dry the concentrated oligosaccharide mixture;

[0050] (2) Preparation of oligosaccharide mixture solution and mobile phase

[0051] a, the preparation of oligosaccharide solution: take this oligosaccharide mixture, use 0.5mol / L NH 4 HCO 3 The solution was made in...

Embodiment 2

[0057] Example 2 Purity Determination

[0058] The mannuronic acid monomers with different degrees of polymerization obtained after freeze-drying were tested by HPLC and MS to determine their purity.

[0059] (1) Pre-column derivation high performance liquid chromatography (HPLC) analysis

[0060] Detection instrument: Dionex UltiMate 3000 liquid chromatograph; Chromatographic column: Kromasil C18 (4.6mm×150mm, 5μm); Mobile phase: Phosphate buffer / acetonitrile (83:17, V / V);

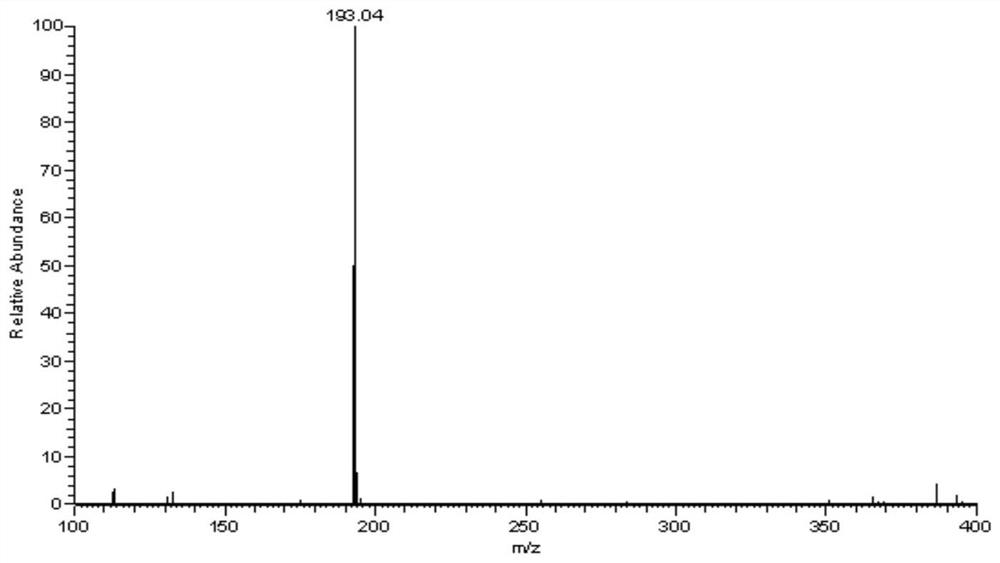

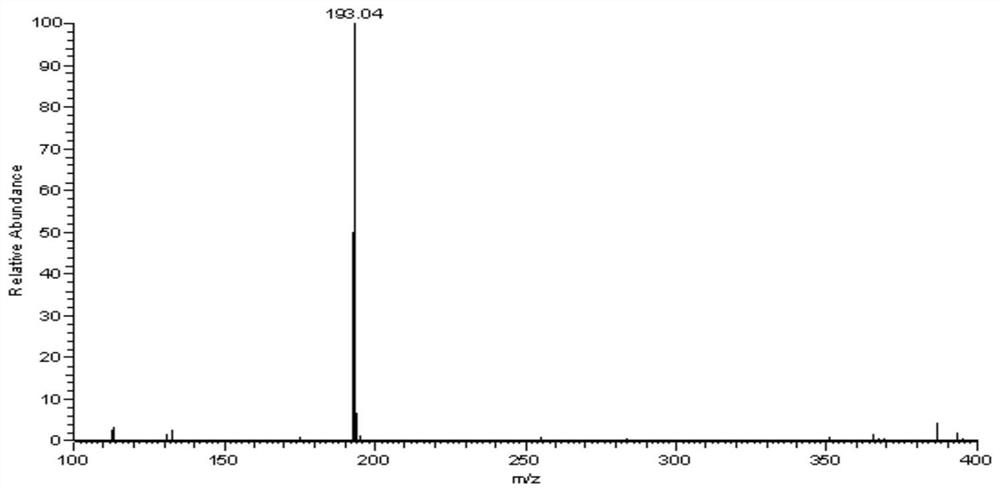

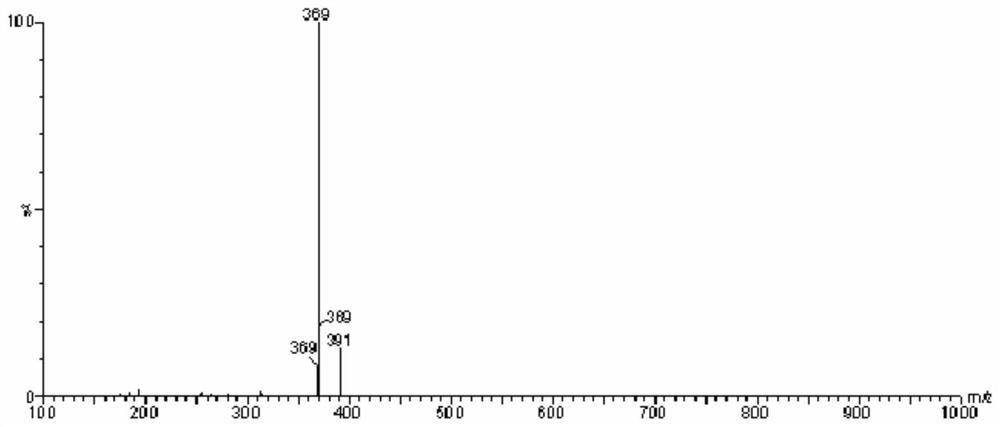

[0061] (2) Electrospray mass spectrometry (ESI-MS) analysis

[0062] Detection instrument: American Micromass Q-TOF Ultima Global quadrupole time-of-flight tandem mass spectrometer; mass spectrometry detection conditions: negative ion detection mode;

[0063] The test results are shown in Figure 2-11. Both the mass spectrogram and the liquid phase chromatogram present a single peak, and the peak shape is symmetrical. The calculated purity of mannuronic acid M1-M10 is above 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com