Self-supporting type truss composite material floor bearing plate preparation method

A technology of composite materials and floor decks, which is applied in the on-site preparation of floors and building components, formwork/formwork components, etc., can solve the problems of affecting the load-bearing effect, building formwork cannot be reused, and is easy to deform, so as to omit support Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

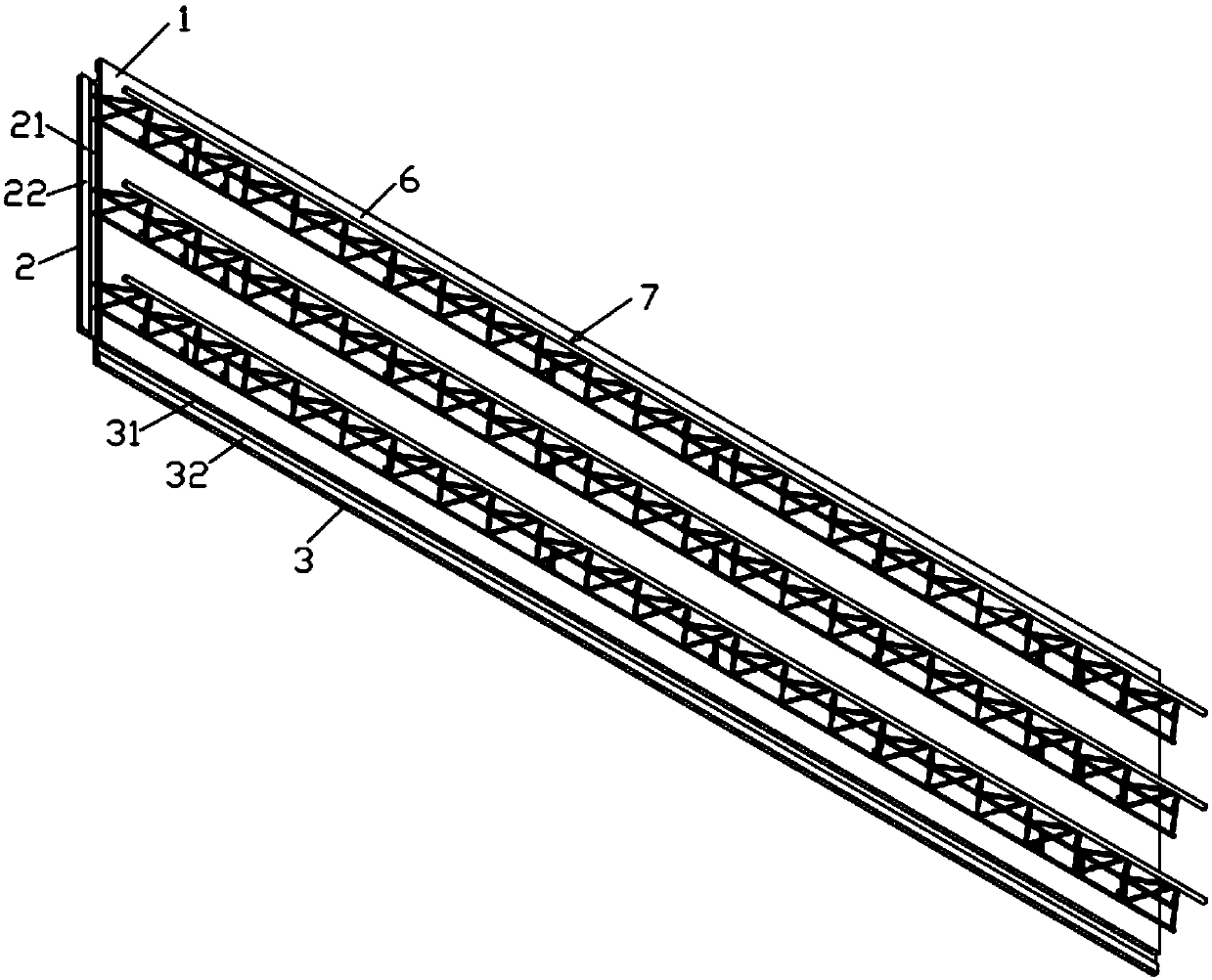

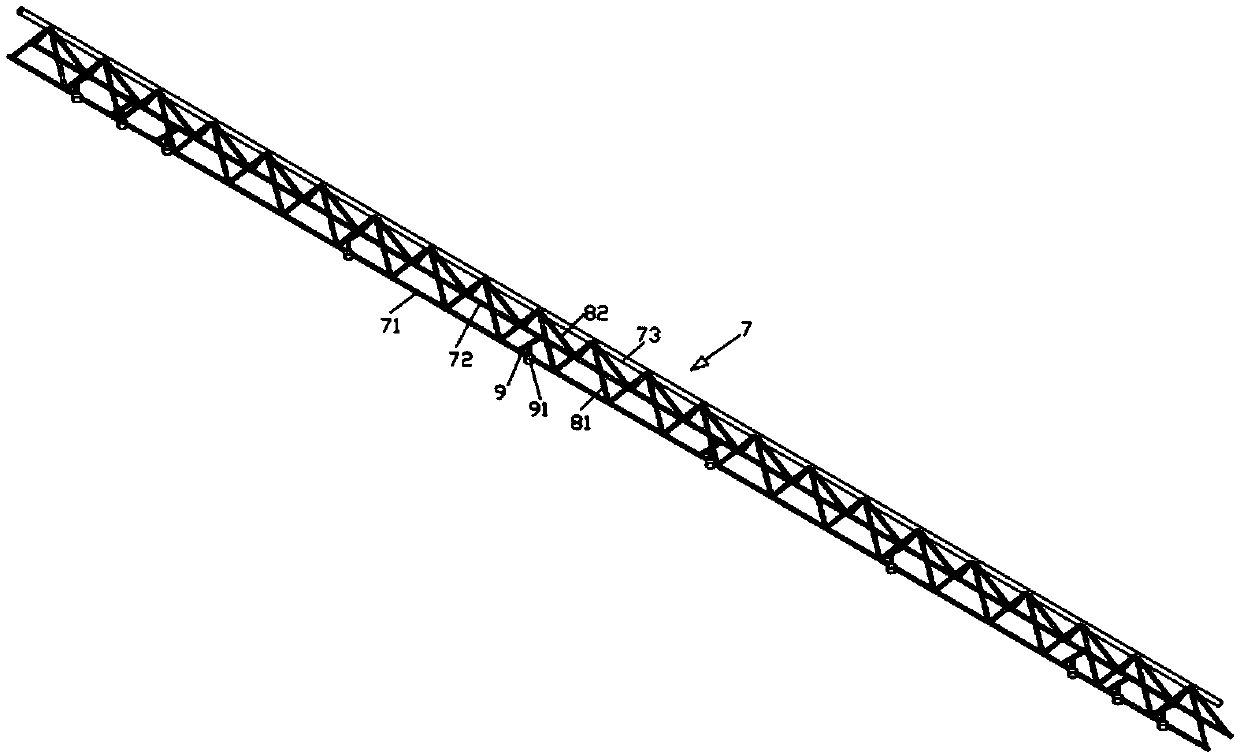

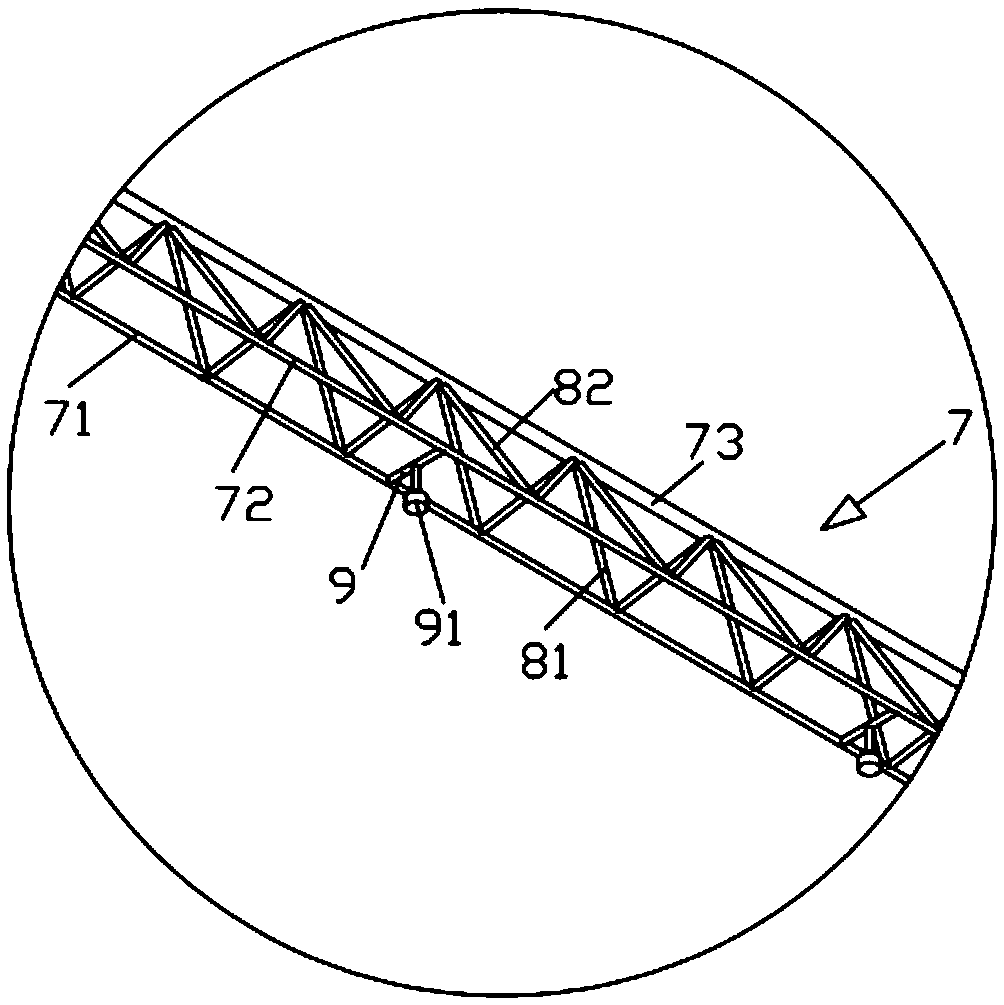

[0028] The invention discloses a method for preparing a self-supporting truss composite floor deck, including the preparation of a building formwork 6, the preparation of a steel bar truss 7, and the assembly of the building formwork 6 and the steel bar truss 7;

[0029] The preparation of building template 6 comprises the steps:

[0030] Step 1: Prepare the building formwork 6, open a recessed space 60 on the back 62 of the building formwork 6, and connect several transverse ribs 51 and longitudinal ribs 52 in the recessed space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com