A semi-grouting sleeve connection structure of assembled components

A semi-grouting sleeve and connection structure technology, which is applied in the direction of building components, structural elements, building reinforcements, etc., can solve the problems of grouting cement not being tight and the stability of the sleeve connection structure being reduced, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

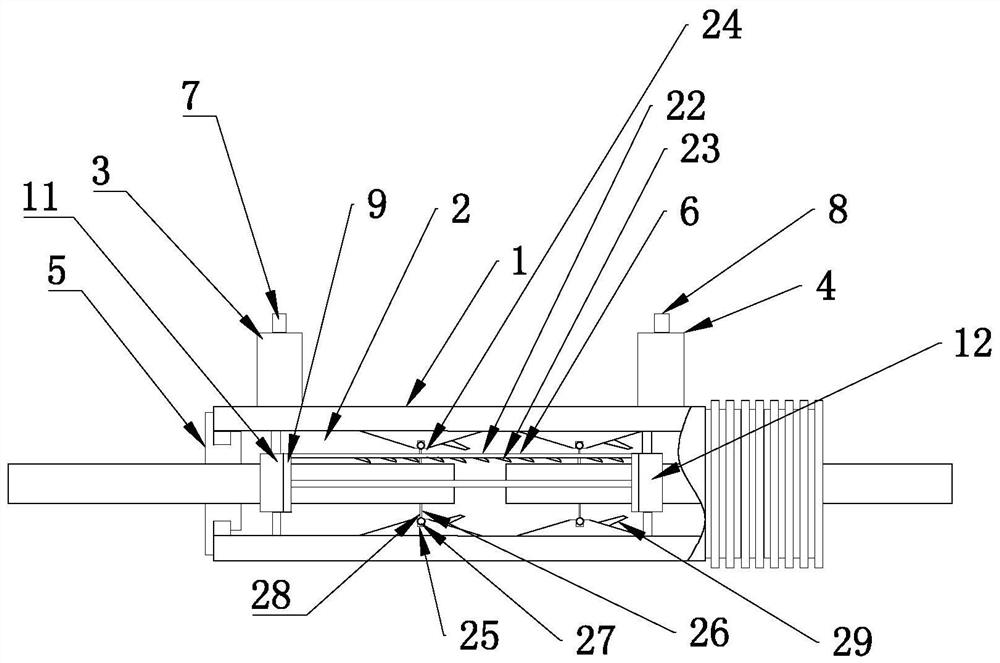

[0017] refer to Figures 1 to 2 As shown, the embodiment is described: the present invention provides a semi-grouting sleeve connection structure for assembled components, including a cylinder body 1, a through groove 2 is arranged in the cylinder body 1, and the outer wall of the cylinder body 1 is provided with a The slurry inlet 3 and the slurry outlet 4 through which the through groove 2 passes, one end of the cylinder 1 is provided with a threaded mounting hole, the other end of the cylinder 1 is provided with a rubber sealing ring 5, and the cylinder 1 is provided with a stirring part 6, the stirring part 6 is in the shape of a hollow sleeve, the stirring part 6 is laterally provided with a first fixed rod 7 and a second fixed rod 8, the first fixed rod 7 protrudes from the slurry inlet 3, and the first fixed rod 7 Two fixed rods 8 pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com