Novel floor installation keel

A kind of keel and floor technology, applied in the field of keel, can solve the problems of complicated floor keel laying process, damage to building strength, hidden danger of living safety, etc., and achieve the effect of smooth floor laying, saving installation cost and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

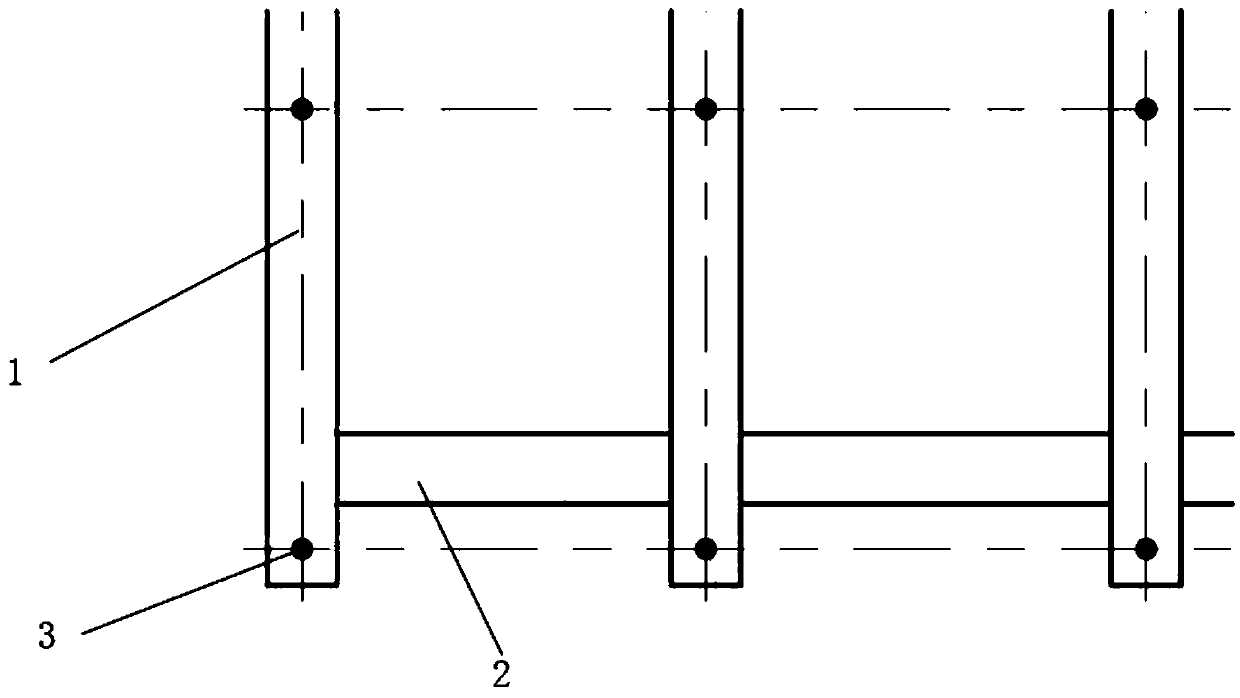

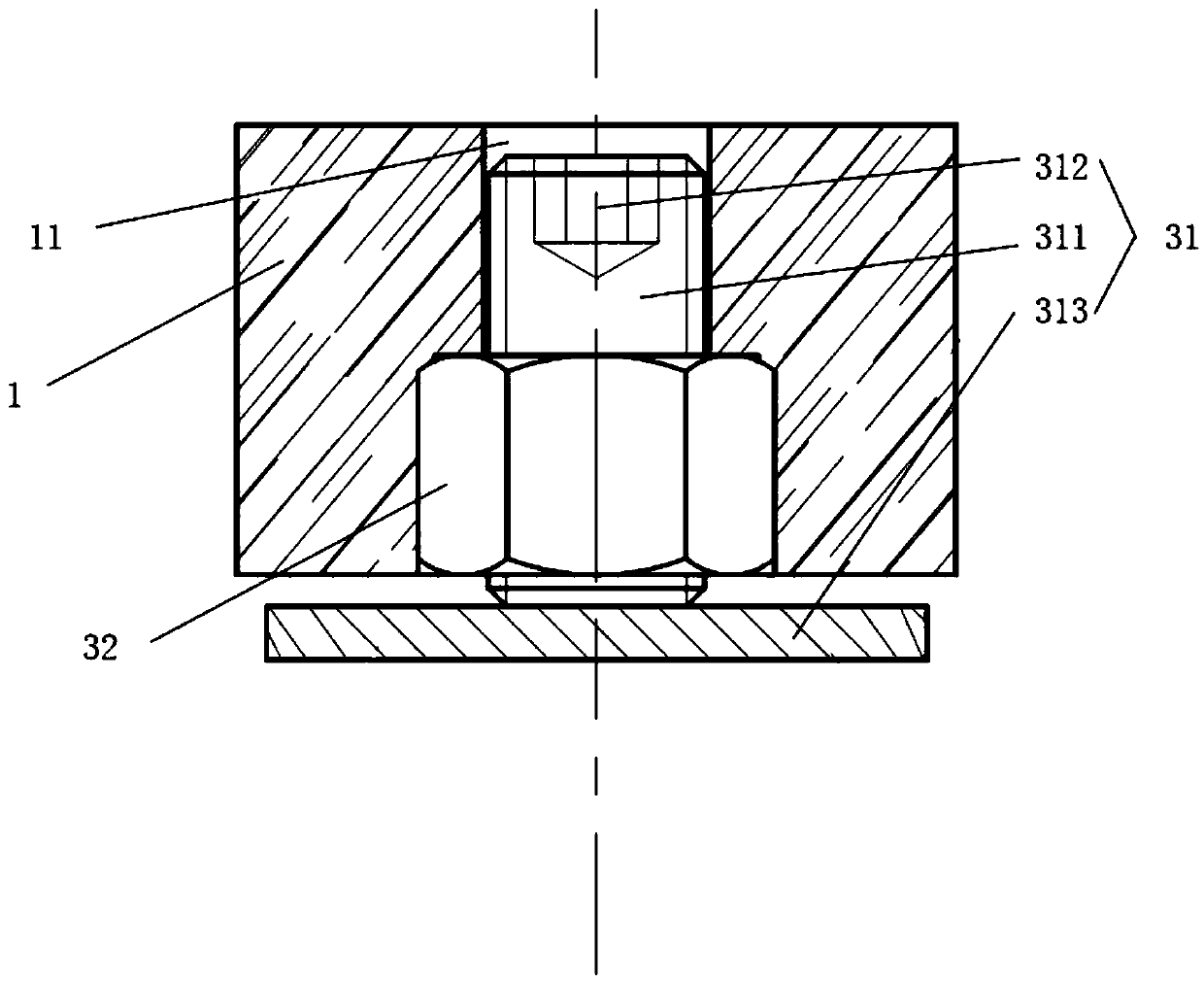

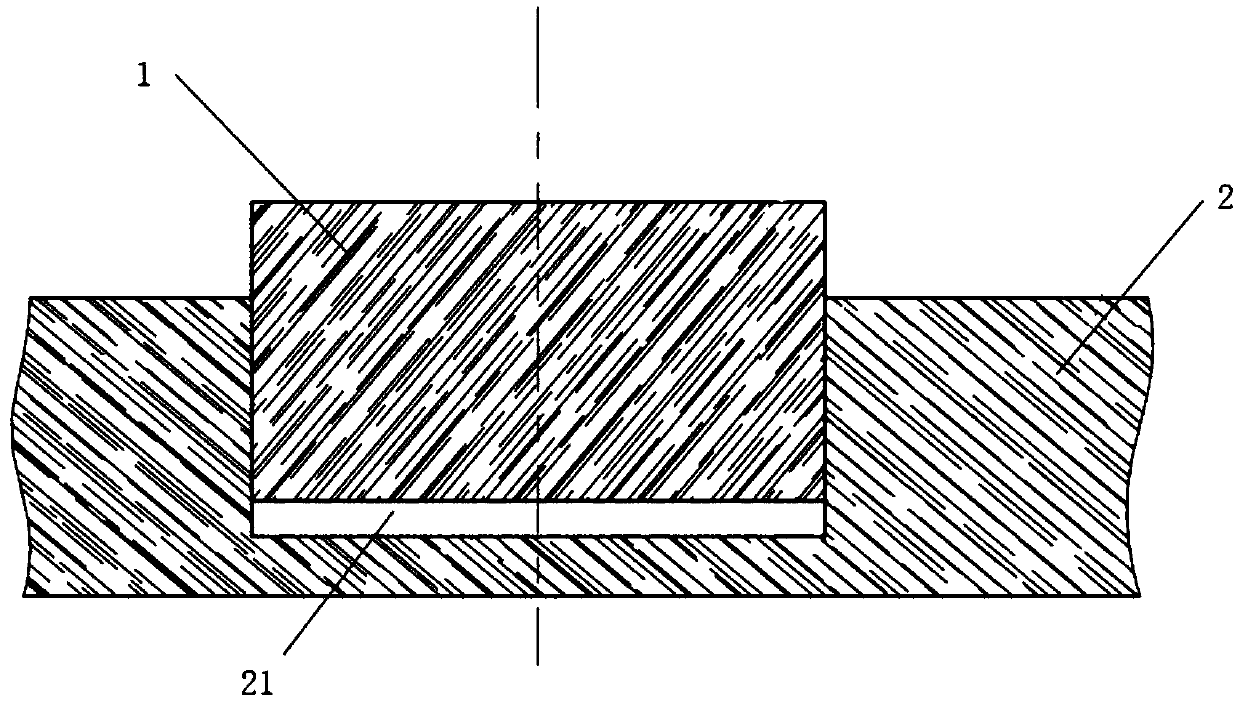

[0032] Such as Figure 1 to Figure 3 As shown, a new type of floor installation keel includes several keel main bodies 1 for supporting, and is characterized in that it also includes positioning keels 2, and the positioning keels 2 are spaced apart along the length direction of themselves for engaging the keel. The engaging groove 21 of the main body 1, the keel main body 1 is provided with adjustable support components 3 at intervals along its length direction, and the adjustable support component 3 includes support nails 31 threadedly connected to the keel main body 1, so The support nails 31 are arranged vertically to penetrate the keel main body 1 .

[0033] Further, the adjustable support assembly 3 includes a fixing nut 32 embedded in the keel main body 1 , and the support nail 31 is threadedly engaged with the fixing nut 32 .

[0034] Further, the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com