Wall surface spraying apparatus

A technology of spraying device and paint box, which is applied in the direction of construction and building construction, and can solve the problems of low efficiency, small spraying area, uneven spraying, etc., and achieve the effect of high spraying efficiency, uniform discharge, and good spraying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

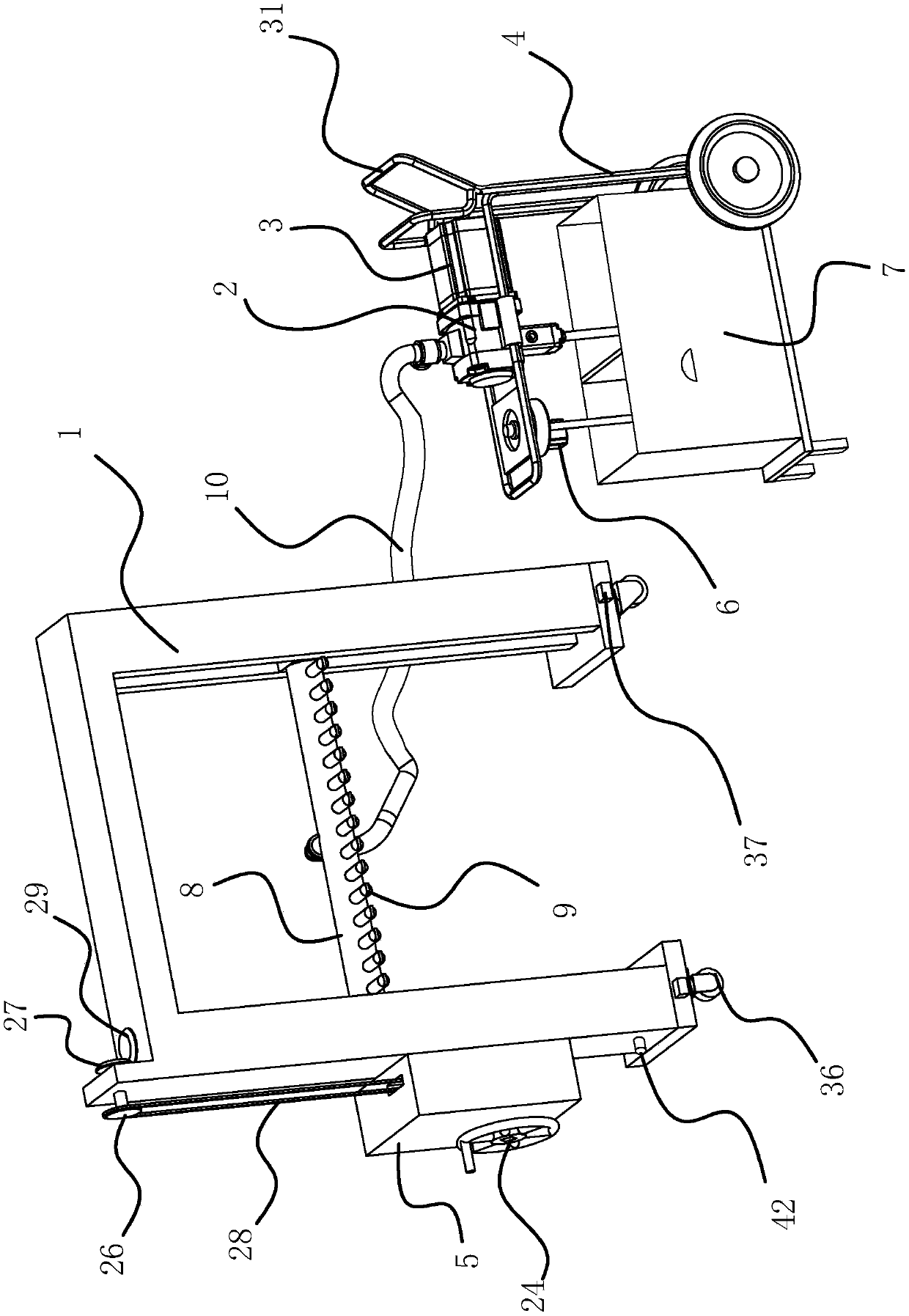

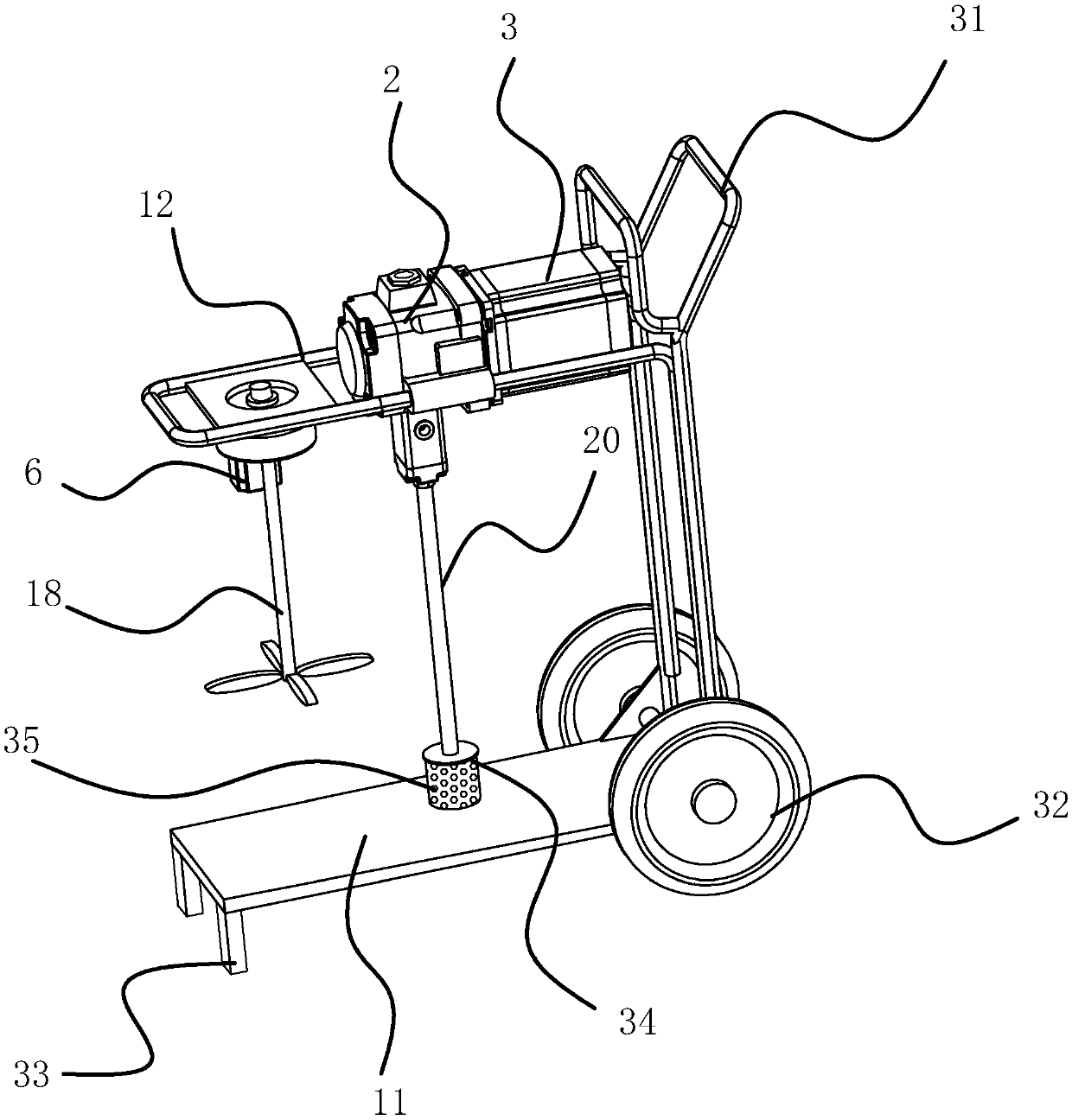

[0030] like Figure 1-4 As shown, the wall surface spraying device includes a gantry 1, a liquid pump 2, a water pump motor 3, a support trolley 4, a stirring motor 6, and a paint box 7. The gantry 1 is provided with a vertically lifting horizontal spraying tube 8, The hollow spraying horizontal pipe 8 has several spraying heads 9 arranged in a line along its length direction. The gantry 1 has a driving mechanism for driving the spraying horizontal pipe 8 up and down. The outlet of the pump 2 is connected to the spraying horizontal pipe 8. There is a feeding pipeline 10 connected between them, the support trolley 4 has a bottom plate 11 and an upper support frame 12, the liquid suction pump 2, the water pump motor 3 and the stirring motor 6 are fixed on the upper support frame 12, and the water pump motor 3 drives the liquid suction pump 2 to operate. The paint box 7 is placed on the base plate 11 of the support trolley 4, and the paint box 7 is divided into two chambers of a ...

Embodiment 2

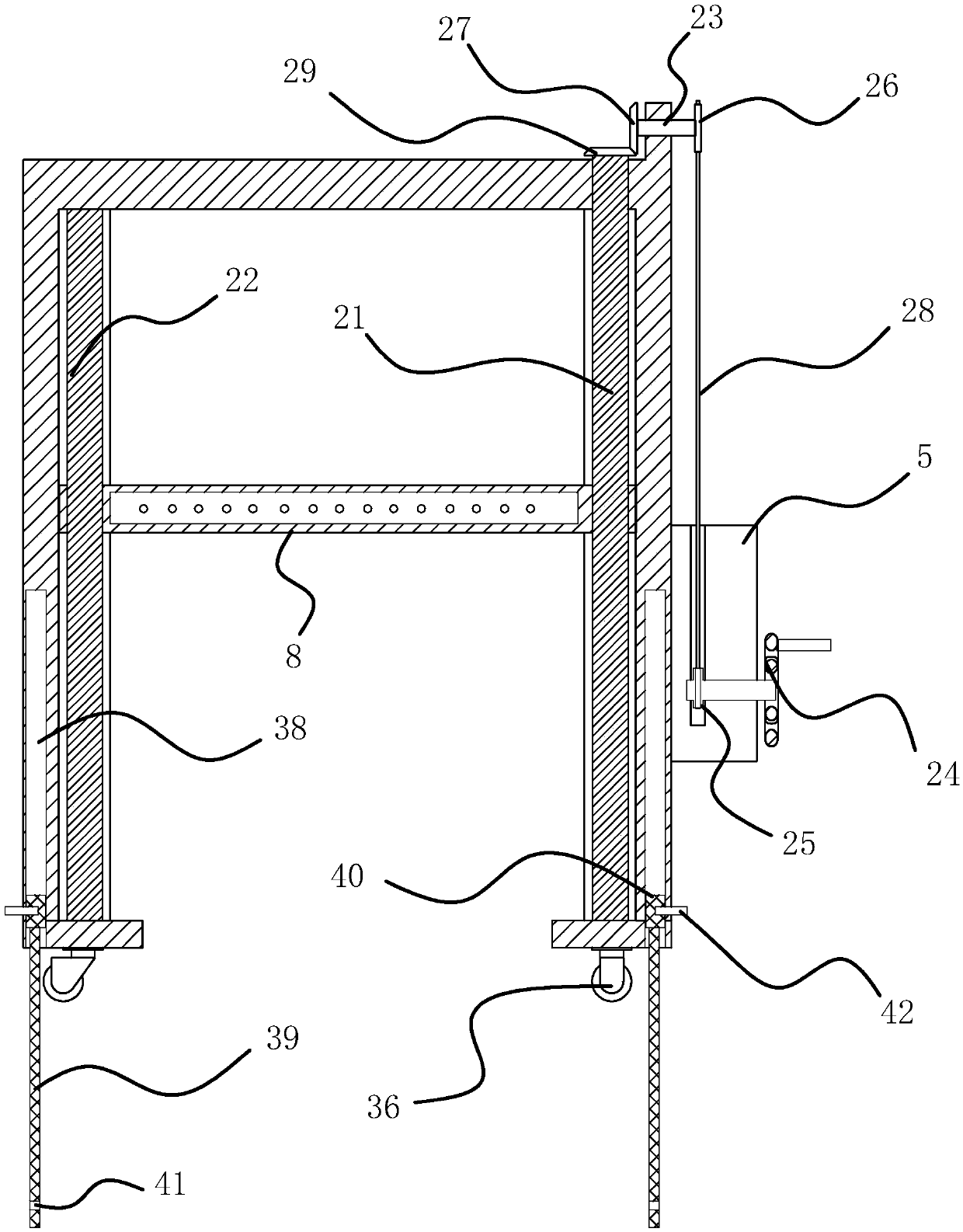

[0040] like Figure 5 As shown, the difference from Embodiment 1 is the drive mechanism. The drive mechanism of this embodiment includes a screw rod 21 and a guide rod 22 that are rotatably connected in the gantry 1, a transmission shaft 23 that is rotatably arranged on the top of the gantry 1, and a lifting motor 30. 1. The control box 5 that is connected to the side of the gantry frame 1, the lifting motor 30 is fixed in the control box 5, the output shaft of the lifting motor 30 is fixedly connected with the driving wheel 25, one end of the transmission shaft 23 is connected with the transmission wheel 26, and the other end is connected Helical gear one 27 is arranged, driving wheel 25 and driving wheel 26 are driven by belt 28, and the upper end of screw rod 21 passes through gantry frame 1 and is fixedly connected with helical gear two 29 meshing with helical gear one 27, and one end of spraying horizontal pipe 8 is screwed on On the screw rod 21 , the other end is sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com