Hydraulic pump detection device for engineering construction machine

A detection device, technology of construction machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

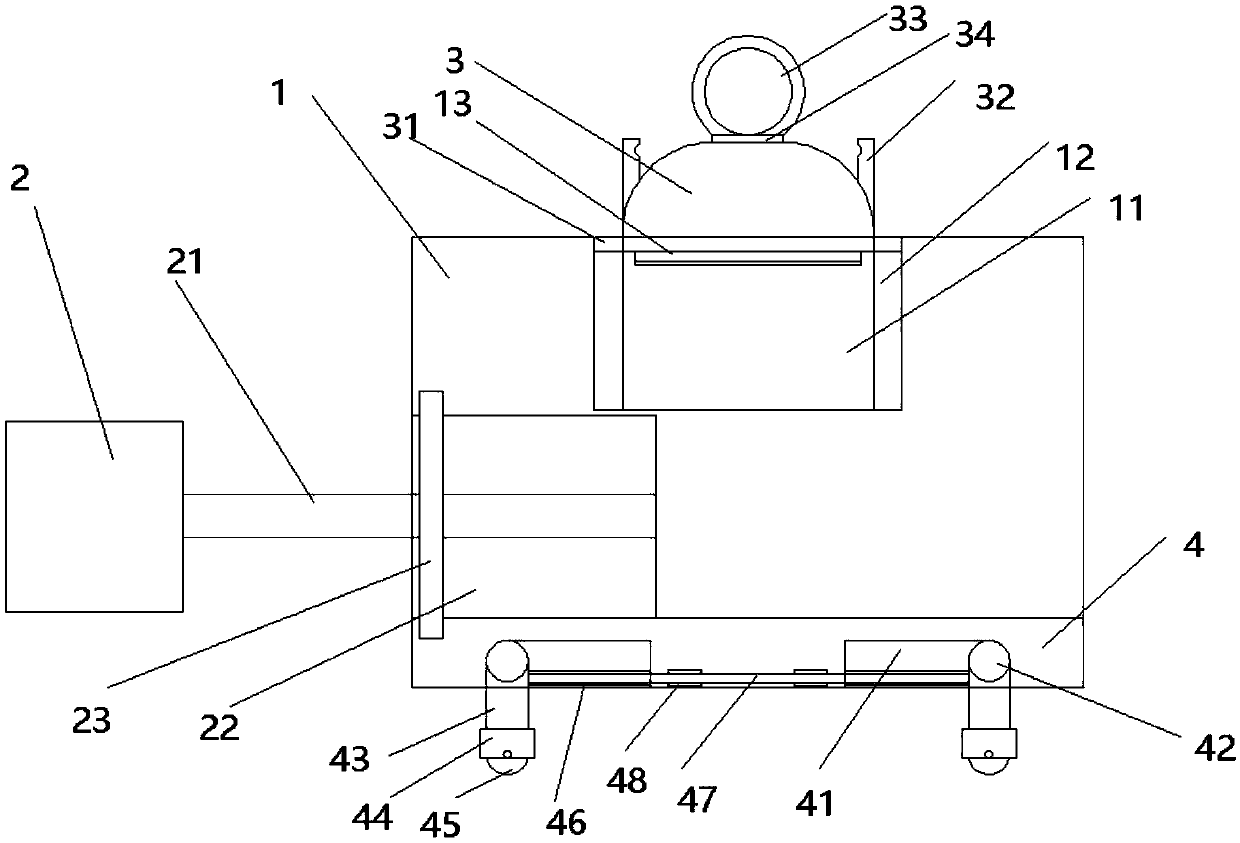

[0022] A hydraulic pump detection device for engineering construction machinery, comprising a box body 1, a detection device 2, a pressure gauge 3 and a base 4, such as figure 1 As shown, a pressure groove 11 is provided at the inner upper end of the box body 1, a pressure chute 12 is provided at both sides of the pressure groove 11, a pressure gauge 3 is provided at the upper end of the pressure groove 11, and a pressure gauge slider 31 is provided at both sides of the lower end of the pressure gauge 3, The pressure gauge slider 31 is slidably connected to the pressure chute 12, pressure gauge handles 32 are provided on both sides of the upper end of the pressure gauge 3, the upper end of the pressure gauge 3 is rotationally connected to the pressure gauge 33, and the left side of the box body 1 is provided with a detection device receiving groove 22, The right side of the detection device 2 is fixedly connected with the right side of the detection device accommodation groove ...

Embodiment 2

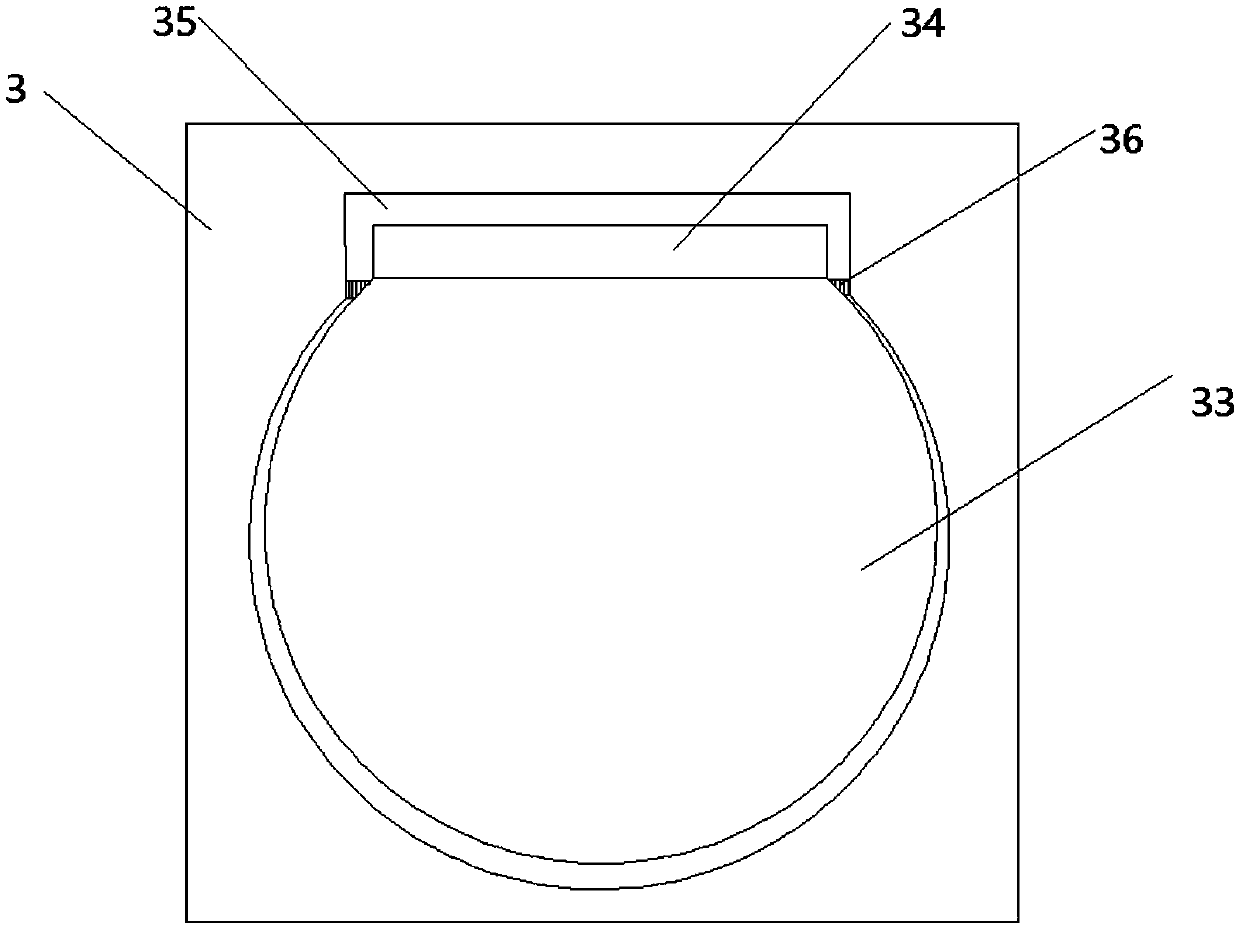

[0024] The difference between this embodiment and embodiment 1 is that, as figure 2 As shown, the upper end of the pressure gauge 3 is provided with a pressure gauge accommodation groove 35, the upper end of the pressure gauge accommodation groove 35 is rotationally connected with the rotating shaft 34, the rotating shaft 34 is fixedly connected with the pressure gauge 33, and the two sides of the pressure gauge accommodation groove 35 are provided with retaining springs 36.

[0025] When the pressure gauge is in use, the pressure gauge 33 is folded up, and the clamp spring 36 clamps the lower end of the pressure gauge 33 to clamp the pressure gauge on the upper end of the pressure gauge receiving groove 35. When not in use, press the clamp spring 36 to release the pressure. The gauge 33 is clamped in the pressure gauge accommodation groove 35 .

Embodiment 3

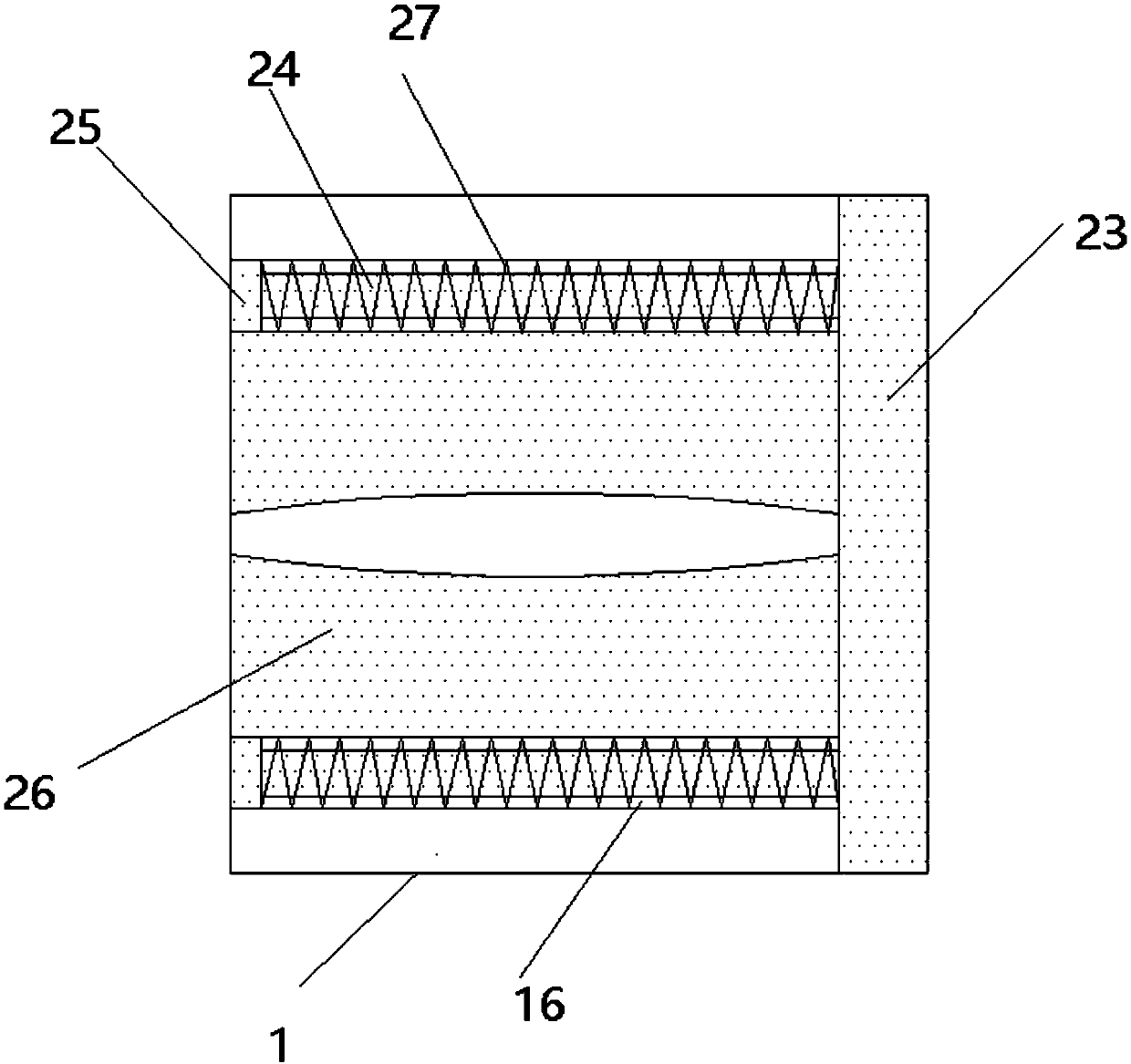

[0027] The difference between this embodiment and embodiment 1 is that, as image 3 As shown, in the middle of the left side of the accommodation groove limit plate 23, a limit clamp 26 is provided, and the box body 1 and the base 4 are provided with a limit plate chute 16, and the upper and lower ends of the limit plate 23 are fixedly connected to the limit column 24 on the left side, so that The left side of the position column 24 is fixedly connected with the limit block 25, and the limit block 25 is fixedly connected with the right side of the limit plate chute 16 through the spring 27.

[0028] When in use, pull the limit plate 23 of the receiving tank outward, take out the detection device 2, put the limit plate 23 back to its original position, pass the connecting line through the middle of the limit clamp plate 26, and connect the detection device 2 to the hydraulic pump out of the machine. Oil port for hydraulic pump pressure detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com