Systems with multiple layers of semiconductor x-ray detectors

An X-ray and detector technology, applied in the field of packaged semiconductor X-ray detectors, can solve the problems of difficult and impossible production of detectors with large areas and a large number of pixels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

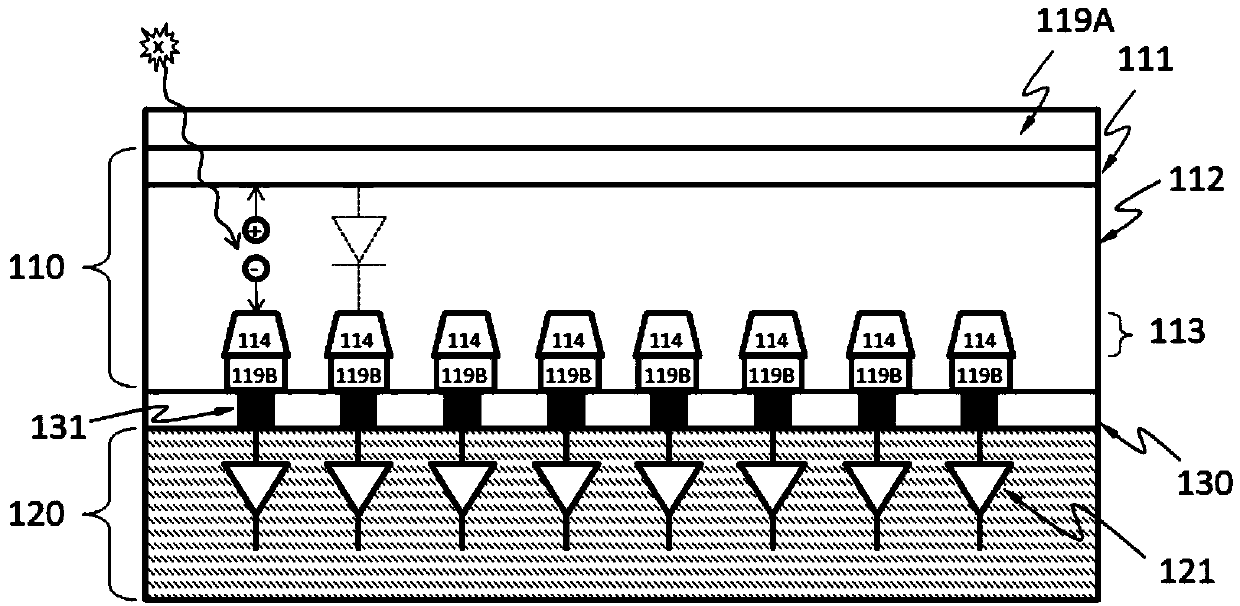

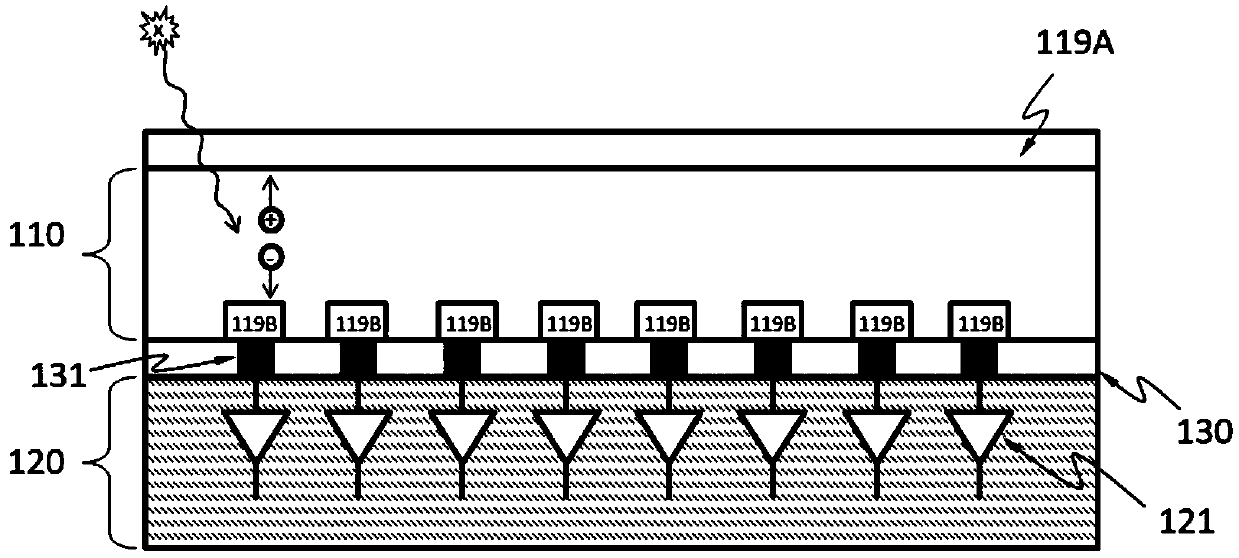

[0069] Figure 1A A cross-sectional view of a detector 100 according to an embodiment is schematically shown. The detector 100 may include an X-ray absorbing layer 110 and an electronic layer 120 (for example, an ASIC) for processing or analyzing electrical signals generated in the X-ray absorbing layer 110 by incident X-rays. In an embodiment, detector 100 does not include a scintillator. The X-ray absorbing layer 110 may include semiconductor materials such as silicon, germanium, GaAs, CdTe, CdZnTe or combinations thereof. Semiconductors can have high mass attenuation coefficients for x-ray energies of interest.

[0070] as in Figure 1B As shown in the detailed cross-sectional view of the detector 100, according to an embodiment, the X-ray absorbing layer 110 may include one or more discrete regions 114 formed by the first doped region 111, the second doped region 113 One or more diodes (eg, p-i-n or p-n). The second doped region 113 may be separated from the first dope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com