A hydraulic double-acting shock and rotary impactor inside a pdc drill bit

A double-acting, drill-bit technology, which is applied in the field of rotary impactors and hydraulic double-acting impact rotary impactors, can solve the problems of large impact force loss and weakening impact effects, etc., and achieves less impact force loss, long service life and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings; the following embodiments are illustrative, not restrictive, and the protection scope of the present invention cannot be limited by the following embodiments.

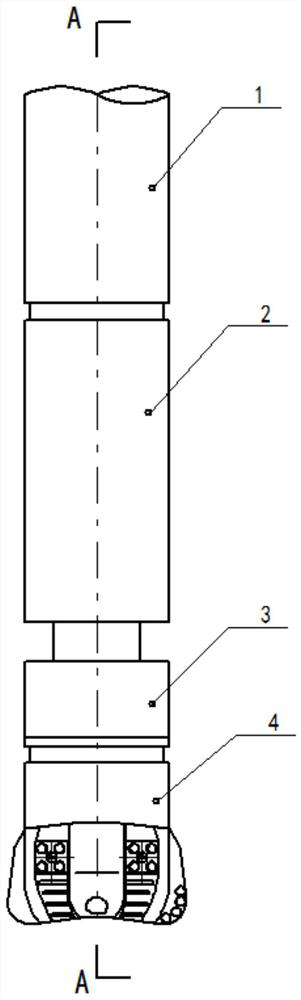

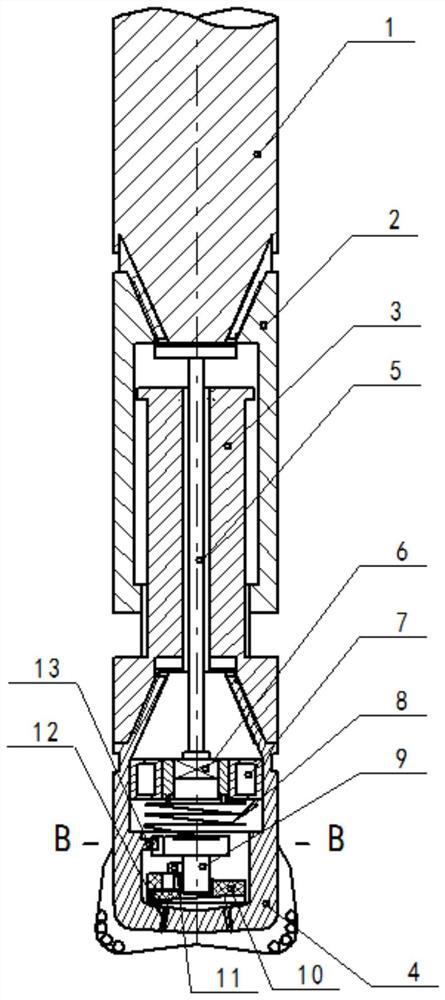

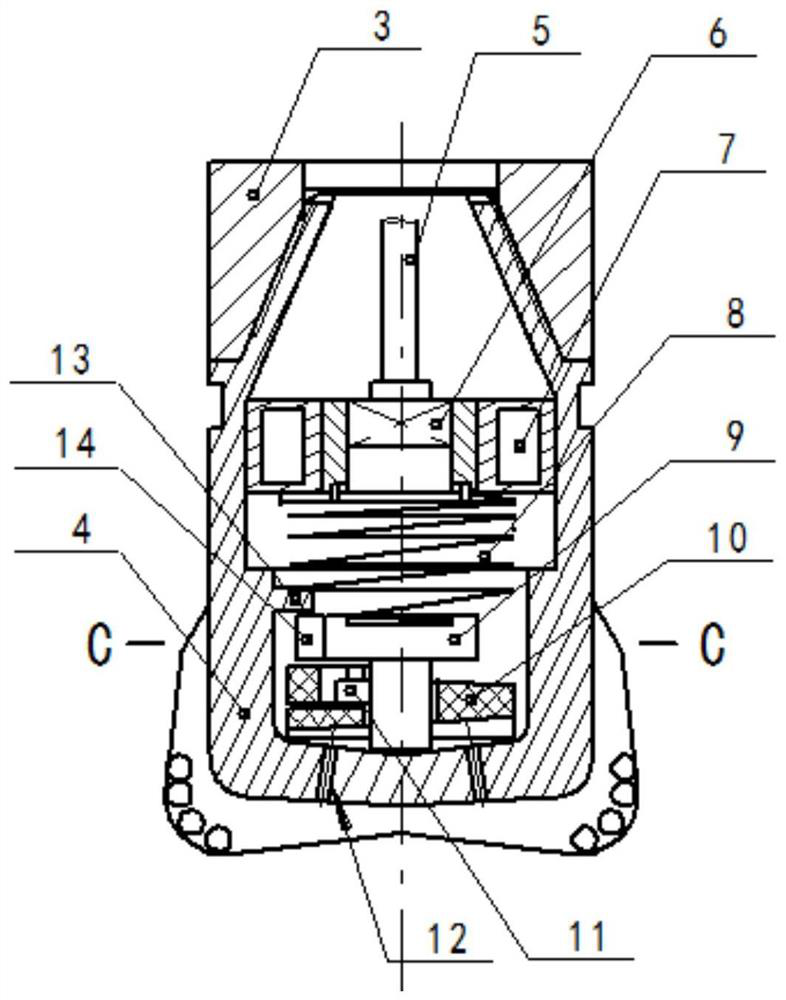

[0023] A hydraulic double-action shock rotary device inside a PDC drill bit, which is composed of a telescopic sub-joint and a shock actuator. 4, the lower end of the telescopic short joint is coaxially connected with the shock actuator in the drill bit.

[0024] The structure of the telescopic short joint is: see figure 1 , 2 , 3. Consists of outer cylinder 2, inner cylinder 3 and ejector rod 5. The upper end of the outer cylinder is made into a tapered inner screw to be threadedly connected to the lower end of the drill collar. The inner cylinder is coaxially slid to install the inner cylinder. The inner cylinder It is a hexagonal or octagonal prism structure, which is guided up and down in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com