Fully automatic connecting device for testing new energy vehicle battery pack

A technology for new energy vehicles and docking devices, which is applied in the directions of measuring devices, parts of connecting devices, connecting/disconnecting of connecting devices, etc. The effect of shortened life and high-speed docking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

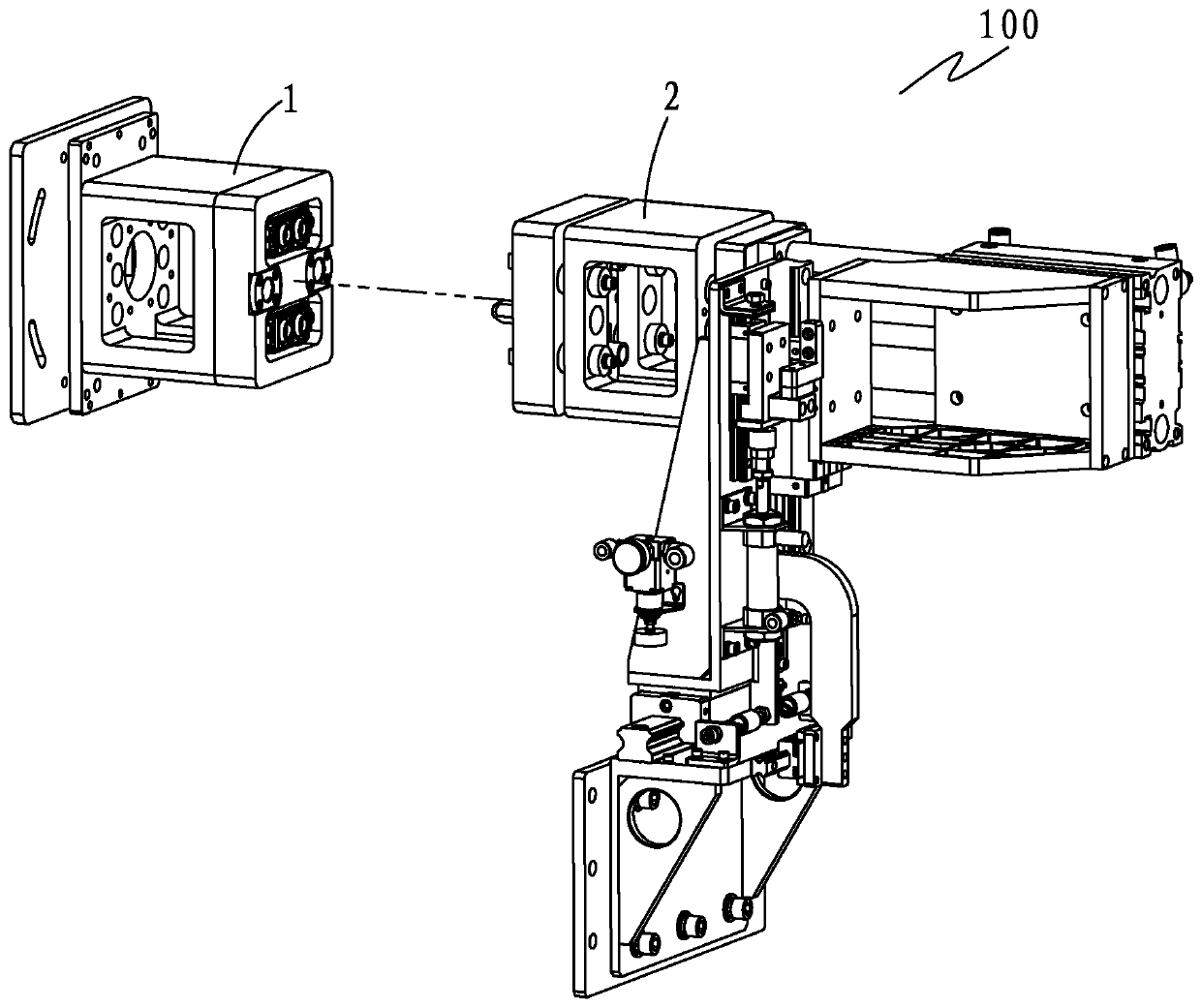

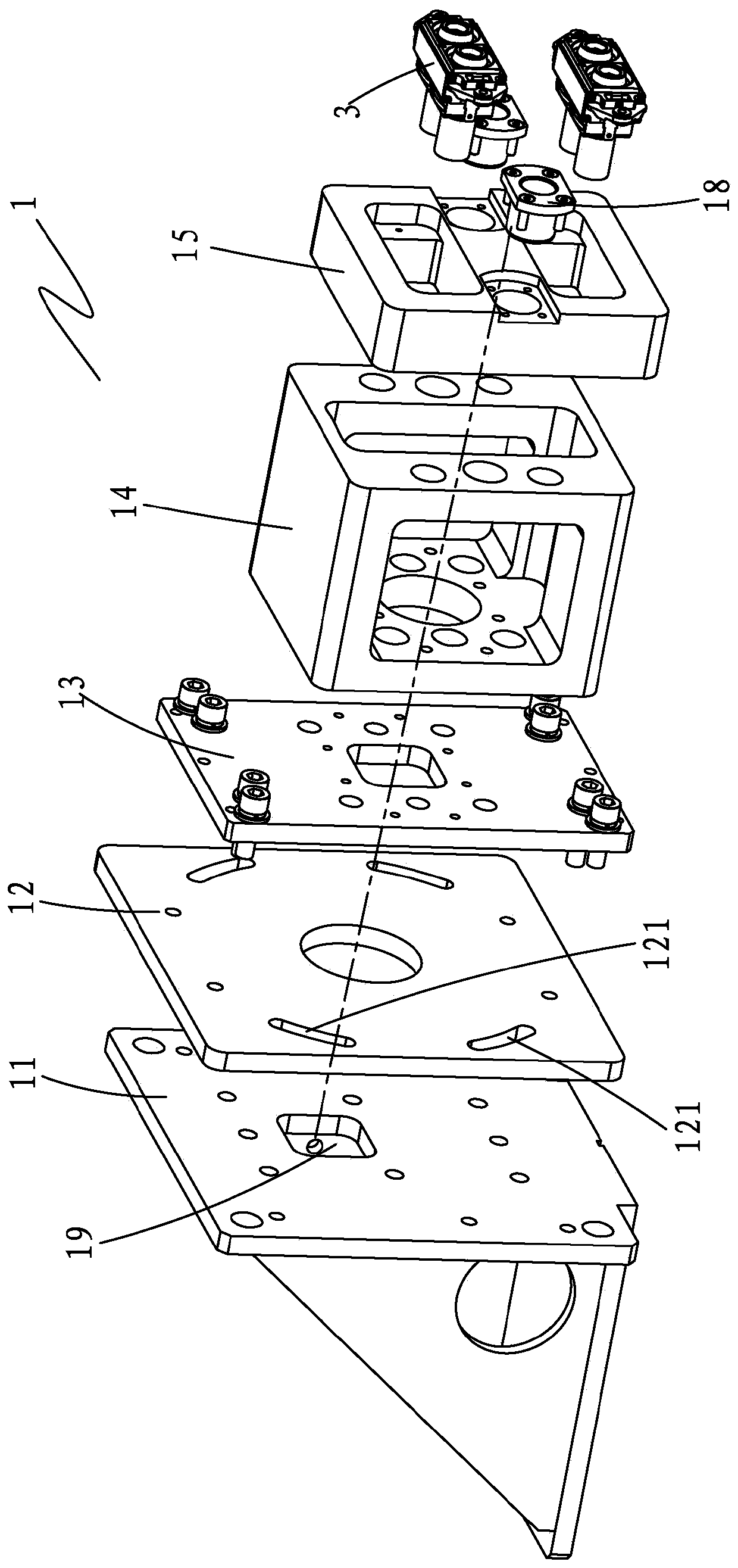

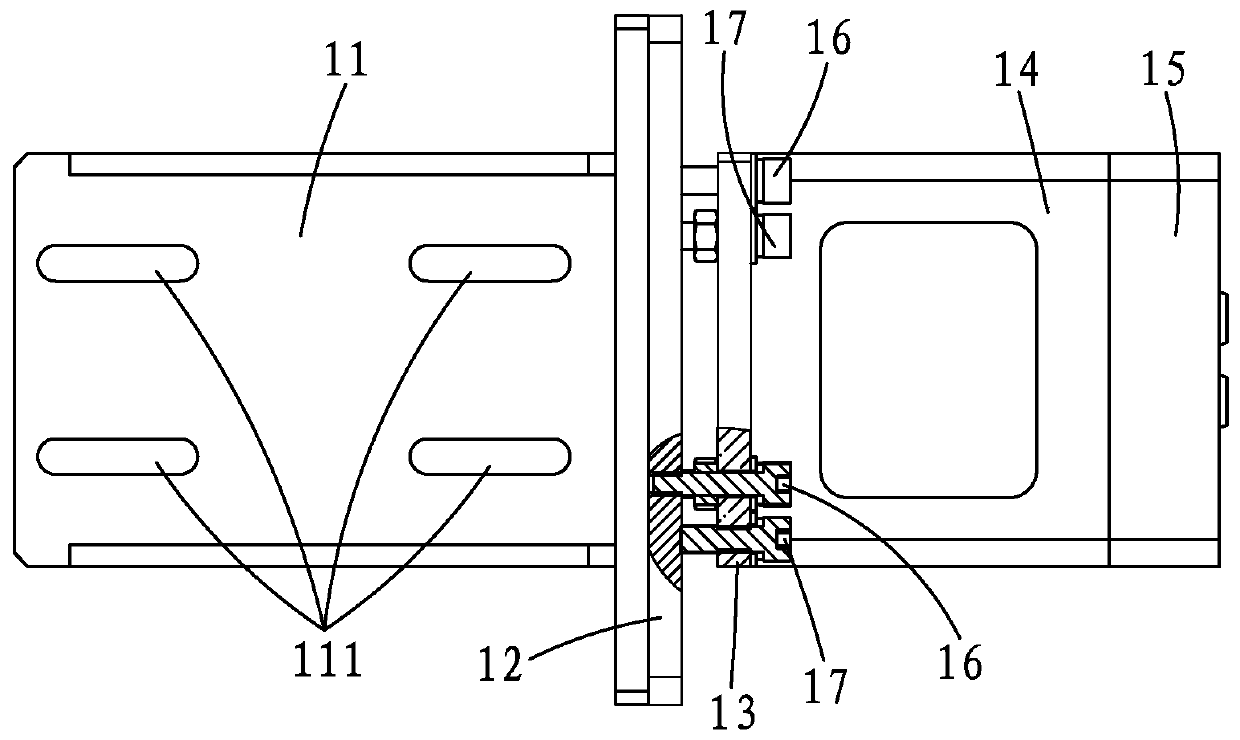

[0039] See Figure 1 to Figure 14 As shown, the present invention is a preferred embodiment of a fully automatic docking device 100 for testing a new energy vehicle battery pack. The fully automatic docking device 100 includes a female head adjustment mechanism 1 and a male head automatic docking mechanism 2. The bottom of the female head adjusting mechanism 1 is adjusted and connected to the battery pack incoming cart (not shown), and the male automatic docking mechanism 2 is fixed on one side of the positioning mechanism (not shown) that cooperates with the battery pack incoming cart, That is to say, in specific implementation, the female head adjustment mechanism 1 needs to be installed on the battery pack incoming vehicle, and the male head automatic docking mechanism 2 needs to be installed in a position that matches the battery pack incoming vehicle. One side of the mechanism, so that automatic docking can be realized; one end of the female head adjustment mechanism 1 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com