Powder cleaning device for atomizing powder manufacturing equipment

A technology for atomizing powder making and powder cleaning, applied in the field of cleaning equipment, can solve the problems of uneven cleaning and difficult cleaning of powder milling equipment, and achieve the effects of comprehensive powder cleaning effect, convenient cleaning and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0038] as the picture shows,

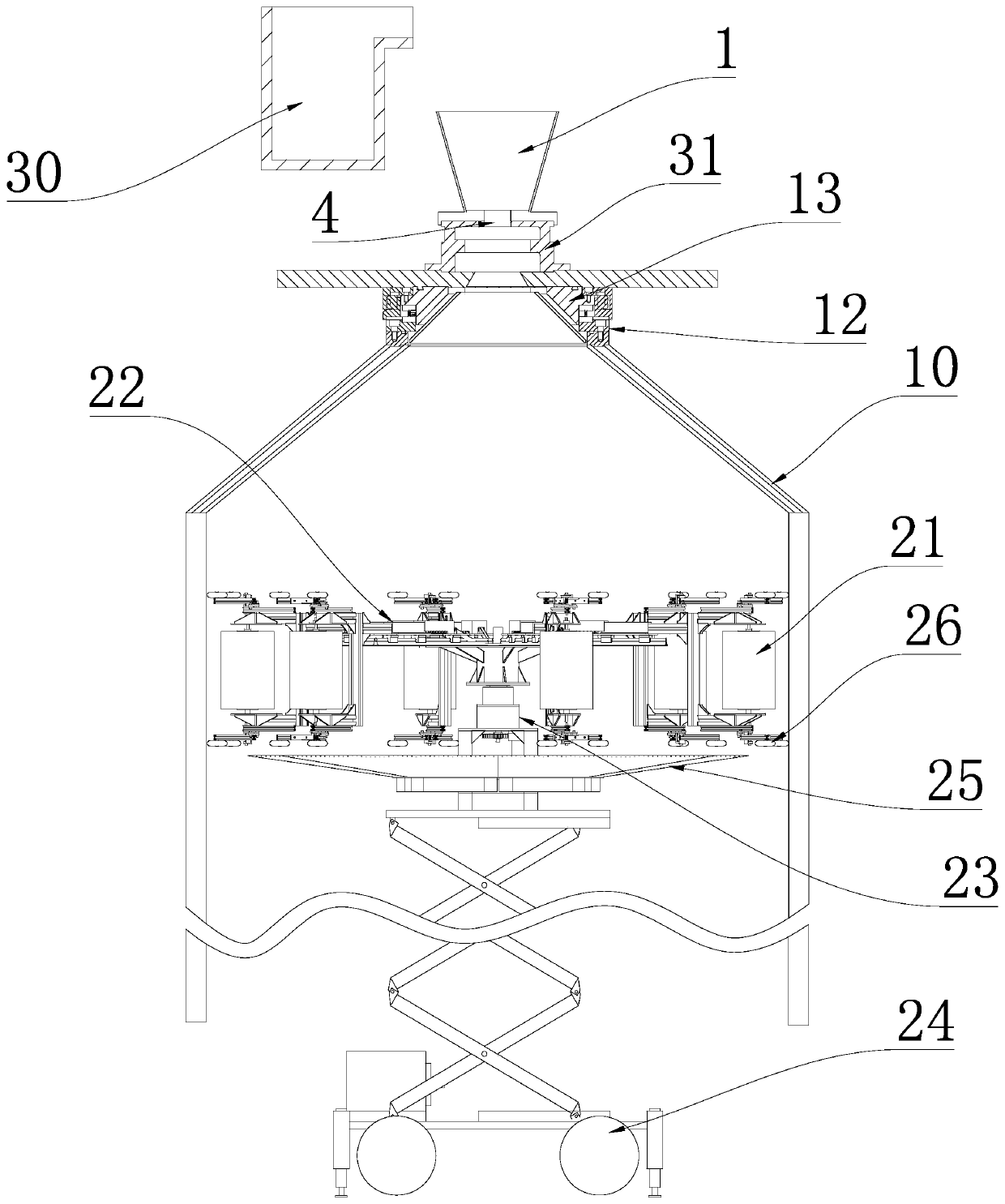

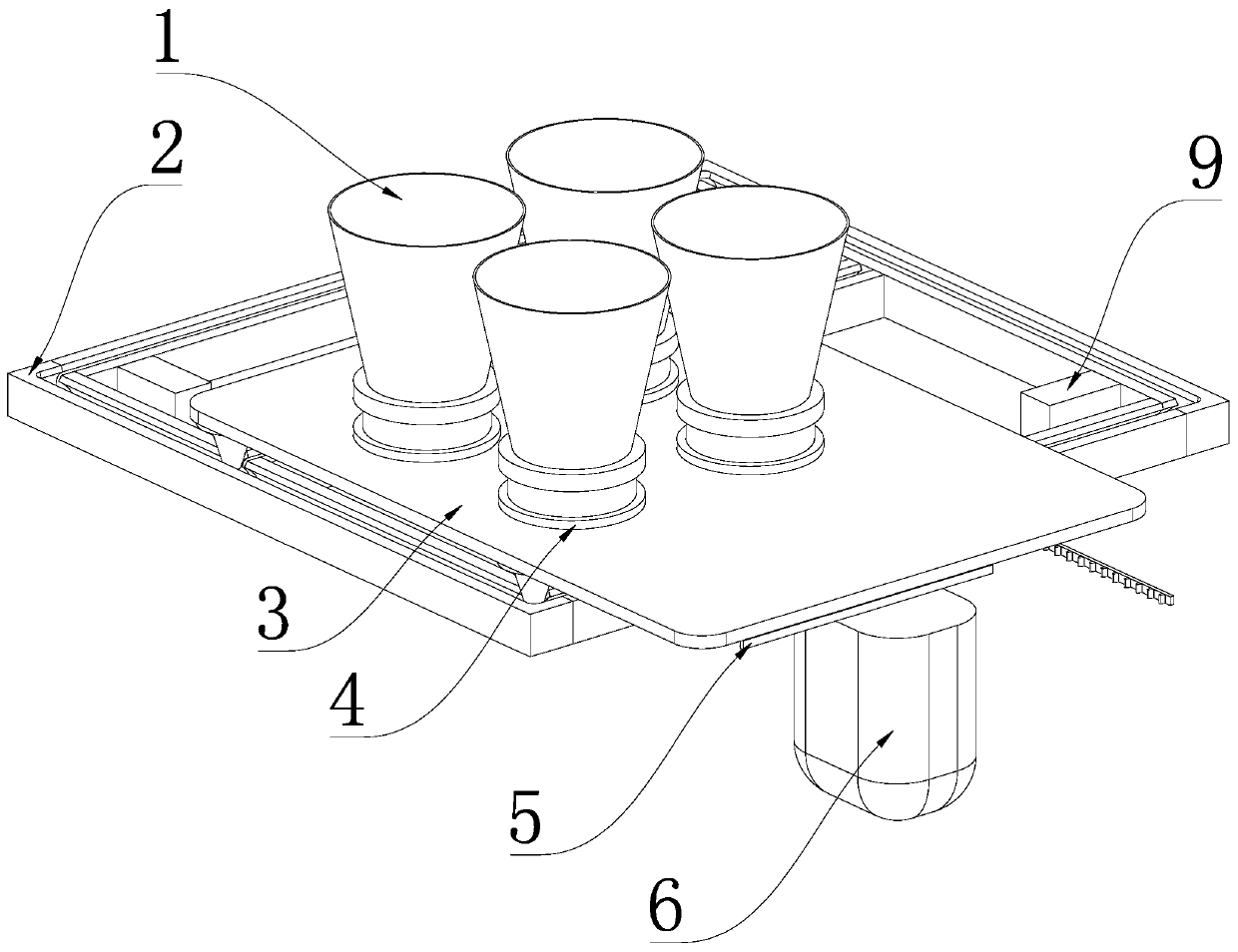

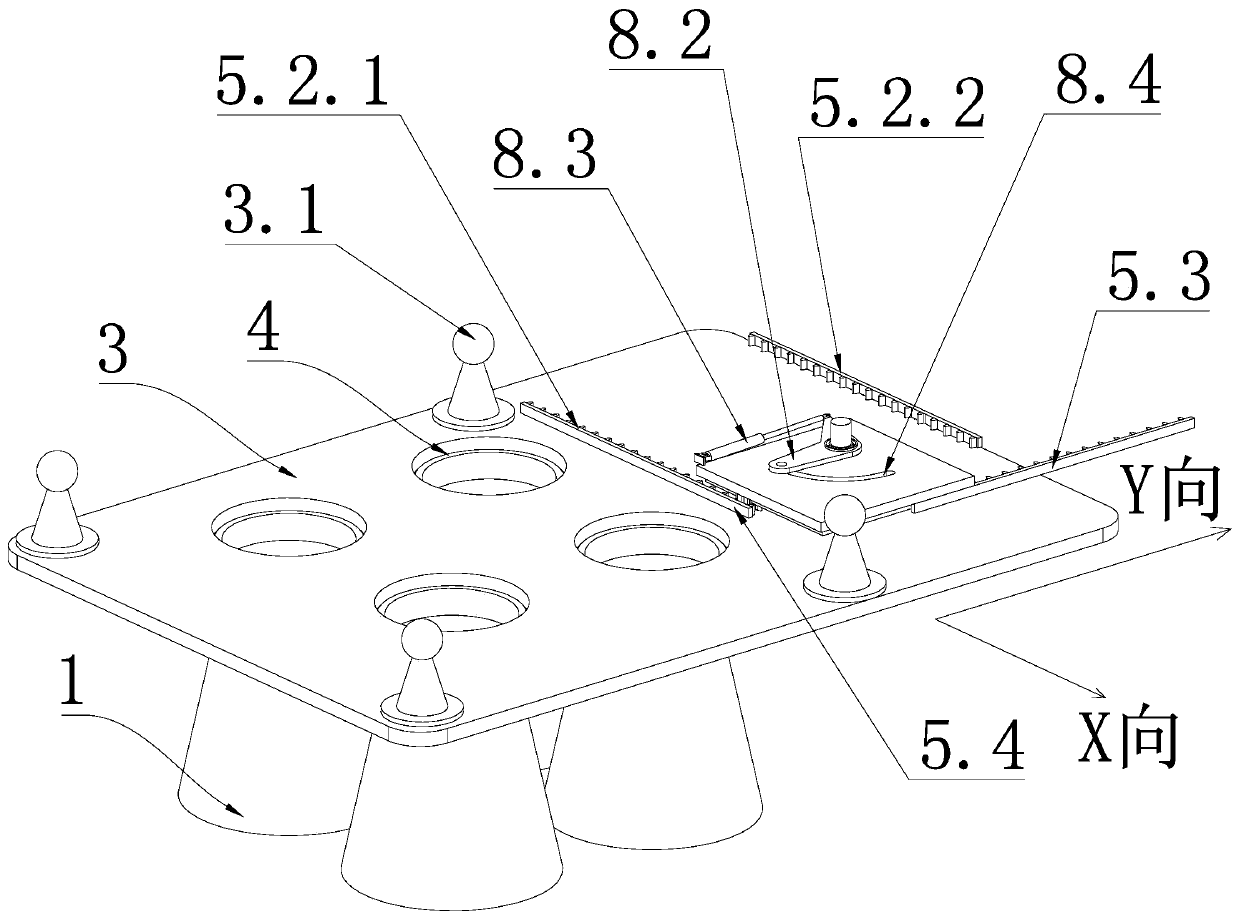

[0039] An atomization pulverization equipment, comprising a melting device, a tundish device, and an atomizing device, the melting device includes a crucible 30, the crucible 30 is used to melt raw materials, the tundish device includes a material bag 1, an atomizer 31, and after melting The metal liquid is poured into the material bag 1, and the atomizer 31 is arranged at the bottom of the material bag 1 for breaking the metal liquid into fine droplets. The atomization device includes an atomization chamber 10, which is used for fine liquid droplets Atomized and finally collected.

[0040] Before preparing different powder materials, it is necessary to clean the inside of the atomization chamber 10 to prevent the newly prepared powder from mixing with the previously prepared powder material. Since the height of the atomiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com