a grinding device

A technology of grinder and machine base, which is applied in the direction of grinding machines, spherical grinders, grinding workpiece supports, etc., and can solve problems such as time-consuming and laborious, uneven grinding effects, and affecting visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (embodiment 1, box type grinder)

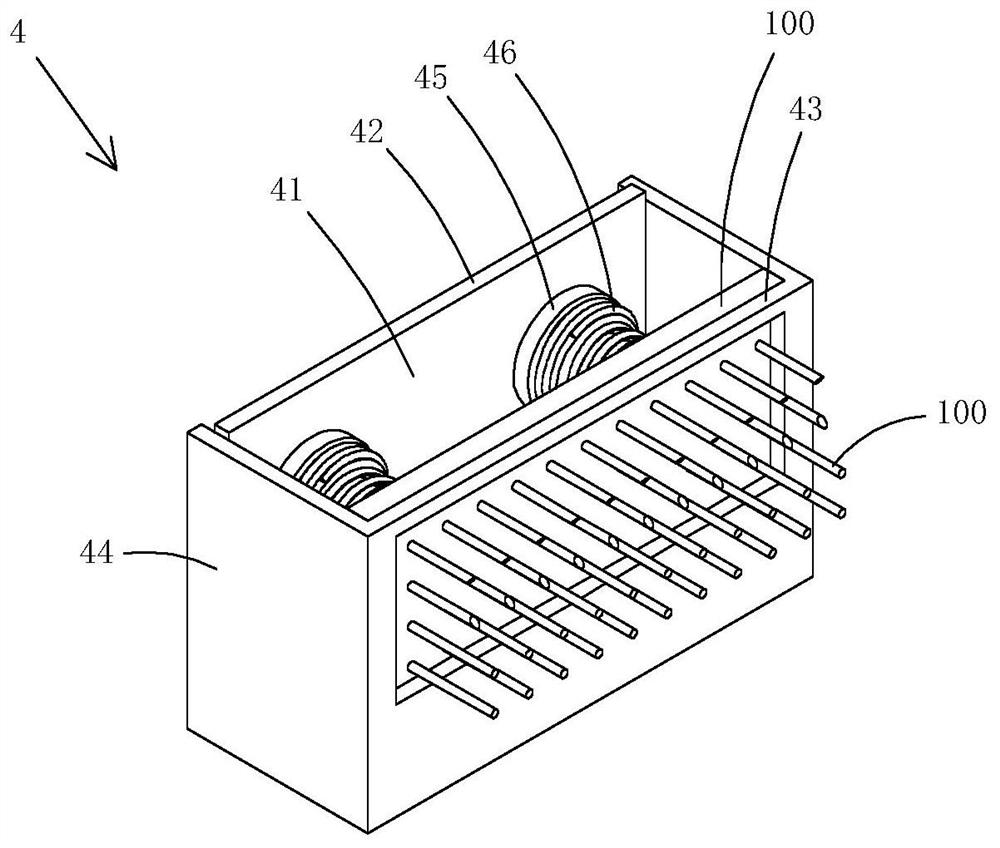

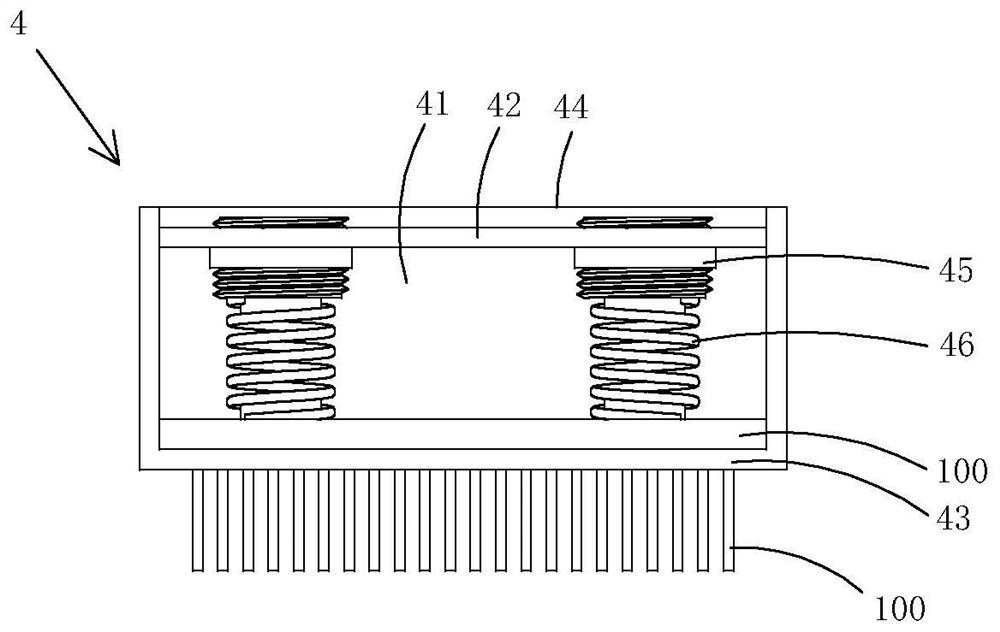

[0016] This embodiment is a box sander, see Figure 1 to Figure 2 As shown, the box type grinder 4 includes a box body 44 provided with a sliding cavity 41, a positioning plate 42 and a baffle plate 43, a scrub brush 100 slidably arranged in the sliding cavity, an adjusting bolt 45 arranged on the positioning plate is rotated, and Compression spring 46; one end of the compression spring abuts on the adjusting bolt, the other end abuts on the plate brush, and presses the plate brush to the baffle plate. Rotating the adjusting bolt can adjust the length of the adjusting bolt protruding into the sliding cavity, thereby adjusting the stress of the compression spring.

[0017] In this embodiment, the size of the workpiece can be ground adaptively, and an adaptive grinding pressure can be applied thereto.

Embodiment 2

[0018] (embodiment 2, grinding device)

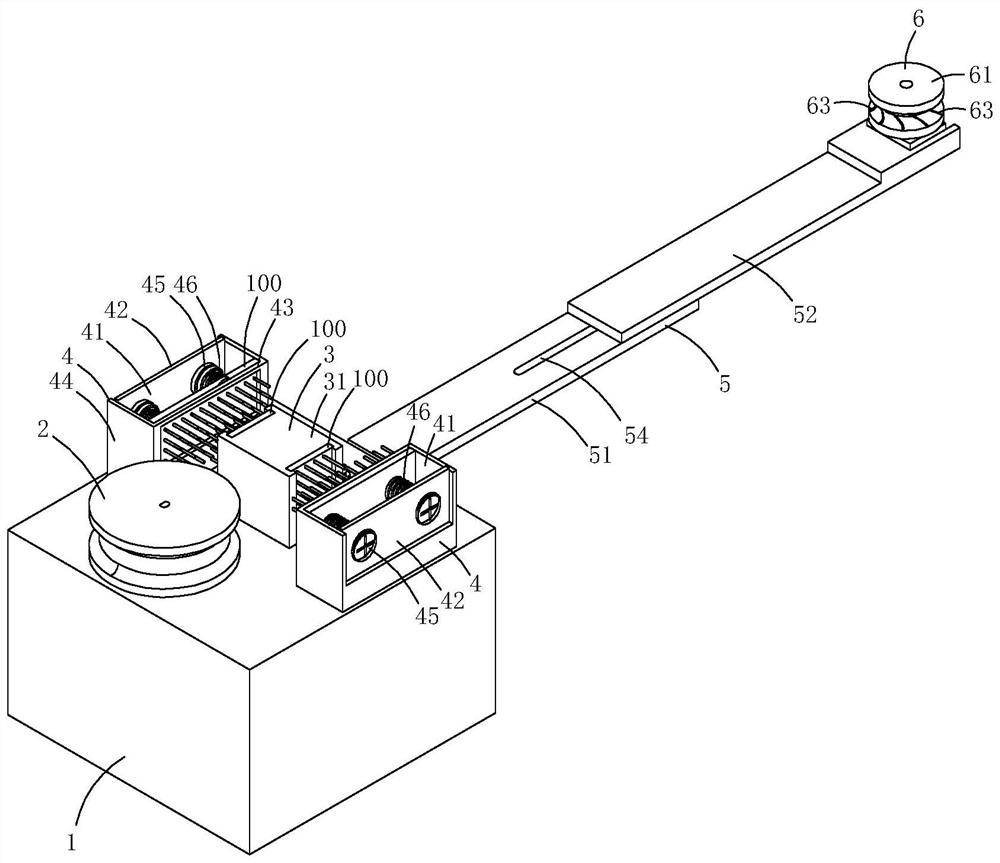

[0019] This embodiment is a kind of chain bead grinding device made by adopting the above-mentioned embodiment 1, see Figure 3 to Figure 7 As shown, it includes a machine base 1, a drive wheel 2 arranged on the top wall of the machine base, a double-headed grinder 3 and a box-type grinder 4, and the drive wheel drive mechanism arranged inside the machine base is arranged on the side wall of the machine base. The combined support plate 5, and the rotary wheel 6 and the rotary wheel driving mechanism 7 arranged on the combined support plate.

[0020] The double-head sander includes a housing 31 fixed on the top wall of the machine base and two scrub brushes 100 arranged on opposite sides of the housing. The housing is provided with slots, and the scrub brushes 100 are plugged into the slots.

[0021] The box sander comprises a box body 44 provided with a slide chamber 41, a positioning plate 42 and a baffle plate 43, a scrub brush 100 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com