Railway vehicle fireless returning device, vehicle and method

A rail vehicle, non-fire return technology, applied in the direction of transportation and packaging, railway car body parts, brake safety system, etc., can solve the problems of inconvenient operation, complicated control, etc., to improve practicability, simplify wiring, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

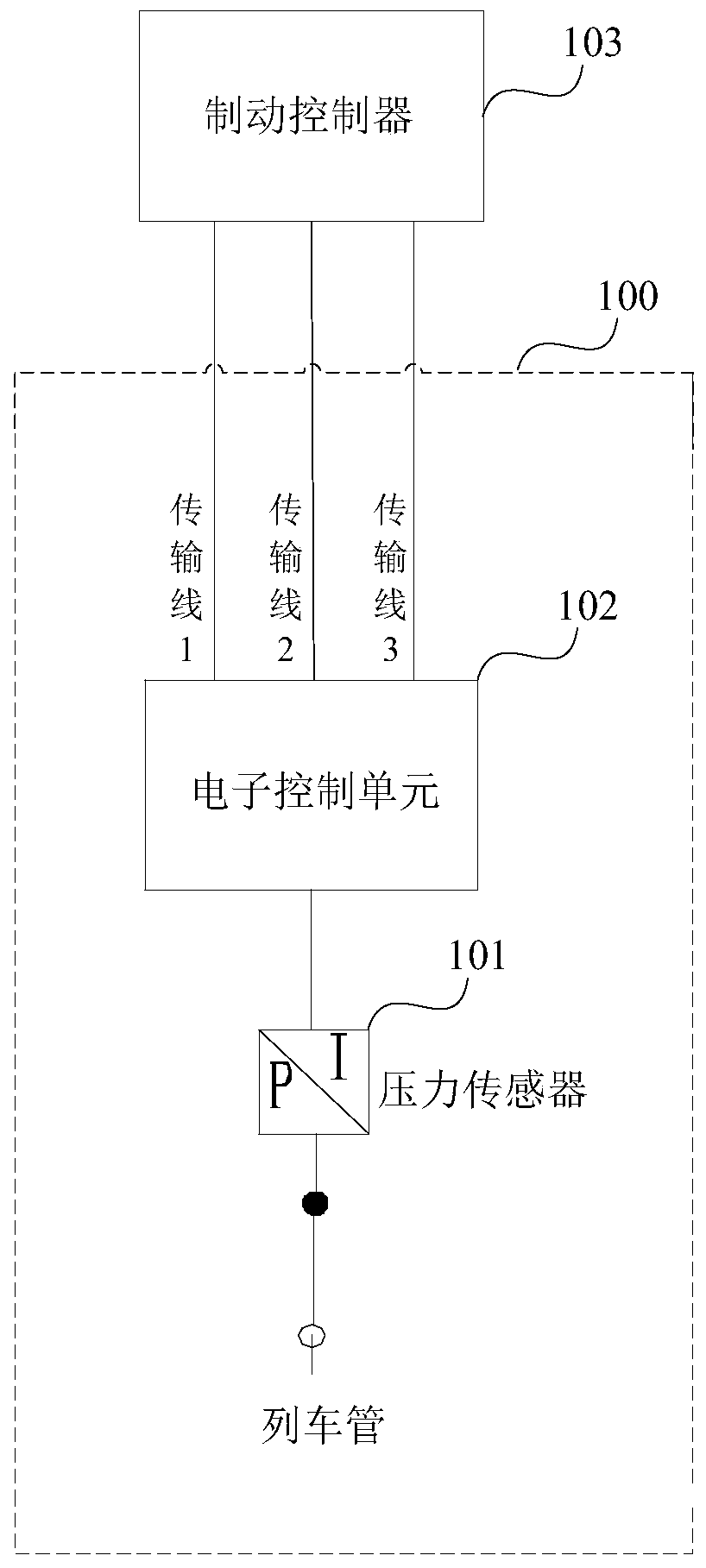

[0040] see figure 1 , which is a schematic diagram of a fire-free return device for a rail vehicle provided in Embodiment 1 of the present application.

[0041] The return device described in the embodiment of the present application is arranged on the returned vehicle, and the train pipe of the returned vehicle is connected with the train pipe of the rescue locomotive.

[0042] The loopback device 100 includes: a pressure sensor 101 and an electronic control unit 102 .

[0043] The pressure sensor 101 is used to detect the pressure of the train pipe of the returned vehicle, because the train pipe of the returned vehicle is connected to the train pipe of the rescue locomotive, so the pressure sensor 101 simultaneously detects the train pipe of the rescue locomotive tube pressure.

[0044] When the rescue locomotive brakes, the train pipe pressure decreases, and the pressure sensor 101 detects the change of the train pipe pressure in time, converts the decompression amount of...

Embodiment 2

[0052] The process of sending the brake level to the brake controller by the electronic control unit will be described in detail below in conjunction with the accompanying drawings.

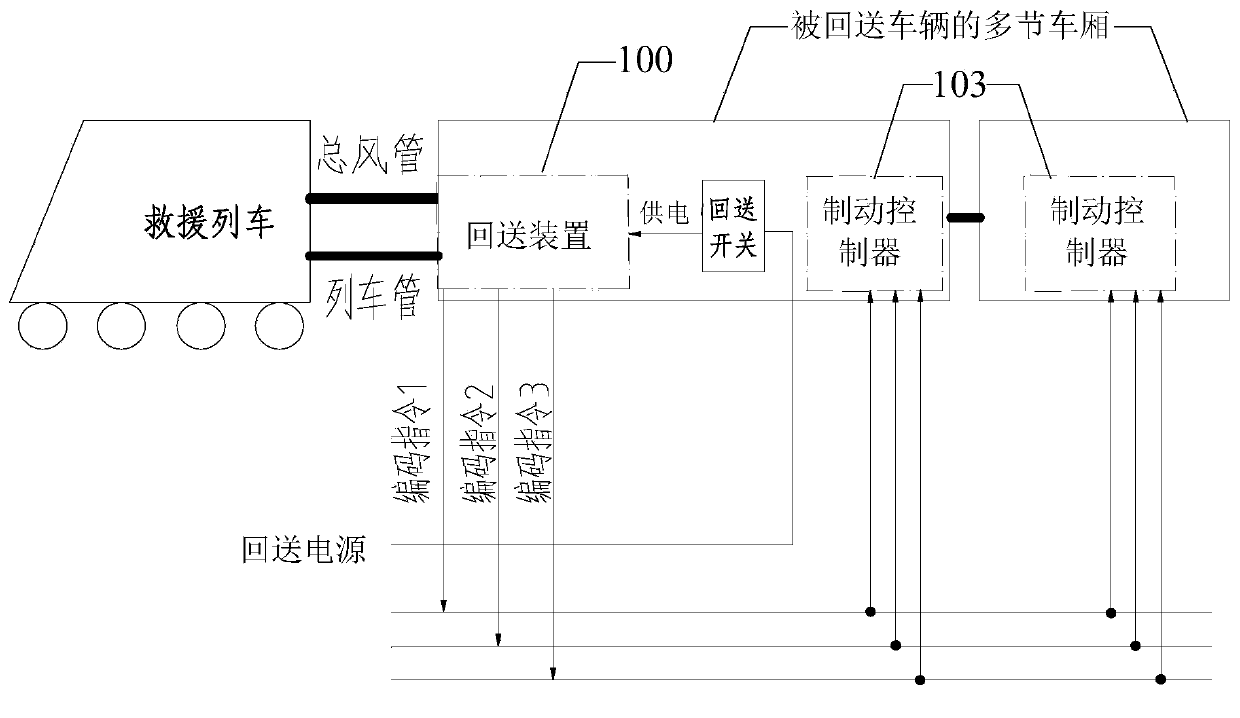

[0053] see figure 2 , which is a schematic diagram of the braking control of the no-fire return device for rail vehicles provided in Embodiment 2 of the present application.

[0054] Such as figure 2 As shown, the rescue train is connected to the train pipe of the returned vehicle and the main air pipe, and the returned vehicle is equipped with a return device 100. The returned vehicle may have multiple carriages, which is not limited in this application. figure 2 An example of a returned vehicle with two carriages is given.

[0055] Each compartment of the returned vehicle is equipped with a brake controller 103, and the electronic control unit of the return device 100 sends the brake level to the brake controller on each compartment through three transmission lines, and the three transmiss...

Embodiment 3

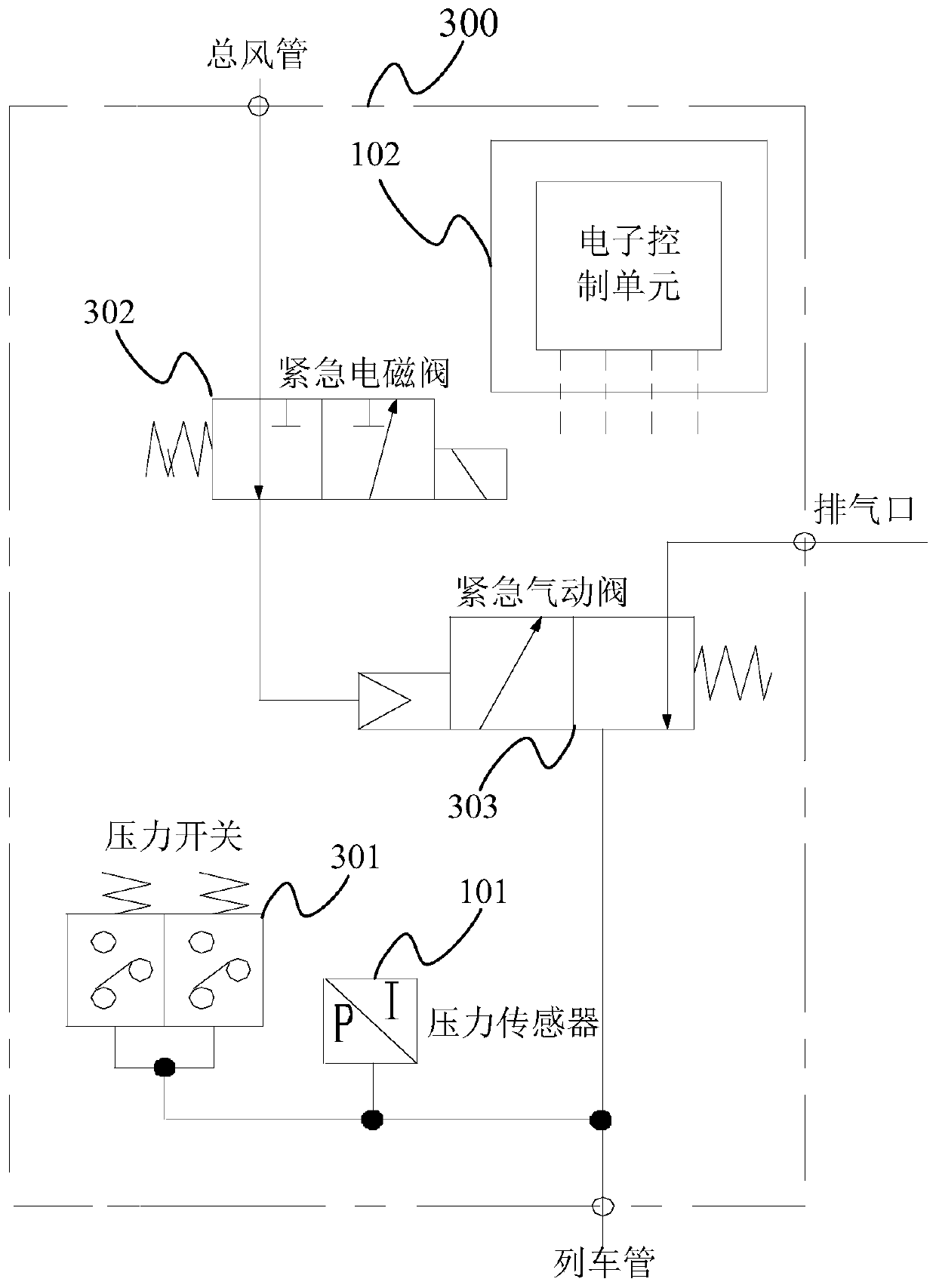

[0065] During the actual fire-free return process, the returned vehicle may have special circumstances such as abnormal disconnection of the safety loop, accidental application of parking, or low total wind pressure, which may lead to automatic emergency braking. In order to avoid the normal traction of the rescue locomotive, the returned vehicle In the case of braking, the embodiment of the present application also provides another fire-free return device for rail vehicles, which will be described in detail below with reference to the accompanying drawings.

[0066] see image 3 , which is a schematic diagram of another fire-free return device for rail vehicles provided in Embodiment 3 of the present application.

[0067] see also Figure 4 , which is a schematic diagram of the braking control of the no-fire return device for rail vehicles provided in Embodiment 3 of the present application.

[0068] Another rail vehicle no-fire return device 300 provided in the embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com