A kind of landfill anti-seepage slurry material based on sodium carboxymethyl cellulose modification and preparation method

A technology for landfills and pulp materials, applied in the field of environmental engineering, can solve the problems of high retardation rate, high cost, complex composition of landfill leachate, etc., and achieve the effects of good durability, stability, plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

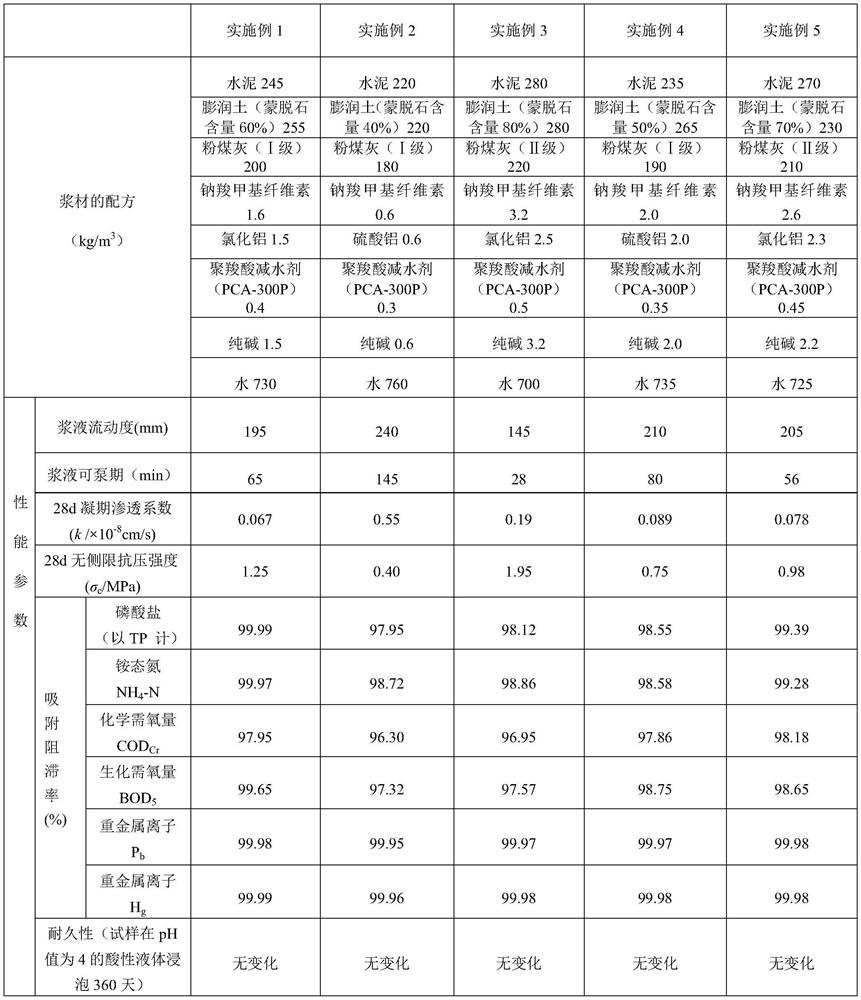

Embodiment 1

[0025] The anti-seepage slurry material of the garbage dump of the present embodiment uses each agent component and content as (unit kg / m 3 ): cement 245, bentonite 255, fly ash 200, sodium carboxymethyl cellulose 1.6, aluminum chloride 1.5, polycarboxylate superplasticizer 0.4, soda ash 1.5, pure water 730.

[0026] ①Take 1.5kg of soda ash, dissolve it in 25kg of water at room temperature, and let it stand for more than 1 hour for use;

[0027] ②Take 1.6kg of sodium carboxymethyl cellulose, dissolve it in 50kg of water at room temperature, and let it stand for more than 2 hours for use;

[0028] ③Take 1.5kg of aluminum chloride, put it into 25kg of water to dissolve at room temperature, and let it stand for more than 2 hours for use;

[0029] 4. get bentonite (montmorillonite mineral content is 60% clay) 255kg, put into above-mentioned sodium carboxymethyl cellulose solution, add soda ash solution and aluminum chloride solution to it then, carry out common modification treat...

Embodiment 2

[0033] The anti-seepage slurry material of the garbage dump of the present embodiment uses each agent component and content as (unit kg / m 3 ): cement 220, bentonite 220, fly ash 180, sodium carboxymethyl cellulose 0.6, aluminum sulfate 0.6, polycarboxylate superplasticizer 0.3, soda ash 0.6, pure water 760.

[0034] ① Take 0.6kg of soda ash, dissolve it in 25kg of water at room temperature, and let it stand for more than 1 hour for use;

[0035] ②Take 0.6kg of sodium carboxymethyl cellulose, dissolve it in 50kg of water at room temperature, and let it stand for more than 2 hours for use;

[0036] ③Take 0.6kg of aluminum sulfate, dissolve it in 25kg of water at room temperature, and let it stand for more than 2 hours for use;

[0037] 4. get bentonite 220kg (montmorillonite mineral content is the clay of 40%), put into above-mentioned sodium carboxymethyl cellulose solution, add soda ash solution and aluminum sulfate solution to it then, carry out common modification treatment...

Embodiment 3

[0041] The anti-seepage slurry material of the garbage dump of the present embodiment uses each agent component and content as (unit kg / m 3 ): cement 280, bentonite 280, fly ash 220, sodium carboxymethyl cellulose 3.2, aluminum chloride 2.5, polycarboxylate superplasticizer 0.5, soda ash 3.2, pure water 700.

[0042] ①Take 3.2kg of soda ash, dissolve it in 25kg of water at room temperature, and let it stand for more than 1 hour for use;

[0043] ②Take 3.2kg of sodium carboxymethyl cellulose, dissolve it in 50kg of water at room temperature, and let it stand for more than 2 hours for use;

[0044] ③Take 2.5kg of aluminum chloride, dissolve it in 25kg of water at room temperature, and let it stand for more than 2 hours for use;

[0045] 4. get bentonite 280kg (montmorillonite mineral content is the clay of 80%), put into above-mentioned sodium carboxymethyl cellulose solution, add soda ash solution and aluminum chloride solution to it then, carry out common modification treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com