Application of acrylic water-absorbent resin in single-component polyurethane waterproof coating and single-component polyurethane waterproof coating and preparation method of single-component polyurethane waterproof coating

A polyurethane waterproof and water-absorbing resin technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as unsuitable moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Using acrylic acid (AA) and acrylamide (AM) as monomers, using N,N'-methylenebisacrylamide (NMBA) as a polymeric crosslinking agent, the concentration of the acrylic acid is 20%, and the concentration of acrylamide is 5%. , the concentration of N,N'-methylenebisacrylamide is 0.5%, and the polyacrylic acid water-absorbent resin 1 is prepared by the inverse suspension method, wherein the cross-linked polymer accounts for 8% of the total amount of the polyacrylic acid water-absorbent resin.

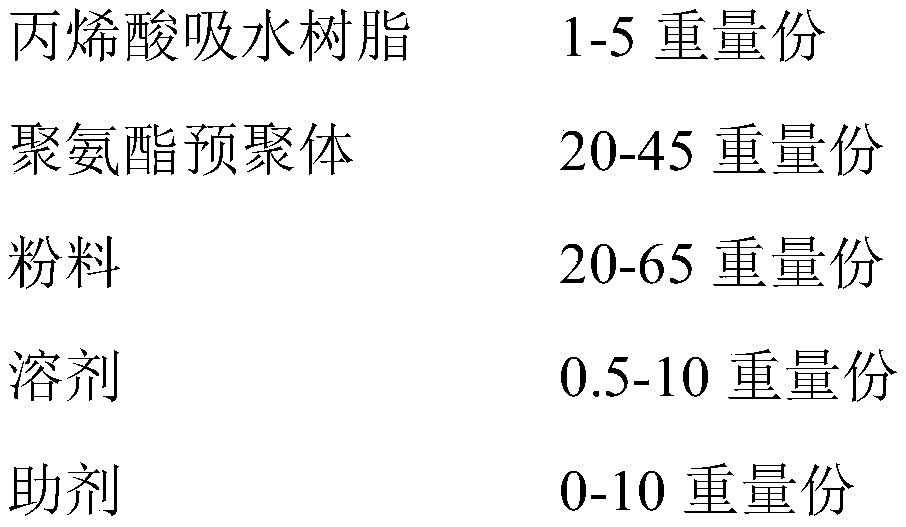

[0029] Further make one-component polyurethane waterproof paint, comprise the component of following parts by weight:

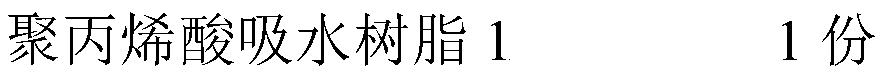

[0030]

[0031]

Embodiment 2

[0033] Using sodium acrylate as a monomer and N,N'-methylenebisacrylamide as a crosslinking agent, the concentration of sodium acrylate is 25%, and the concentration of N,N'-methylenebisacrylamide is 0.3%. The sodium polyacrylate water-absorbent resin 2 was prepared by the inverse suspension method, wherein the cross-linked polymer accounted for 5% of the total amount of the sodium polyacrylate water-absorbent resin 2 .

[0034] Further make one-component polyurethane waterproof paint, comprise the component of following parts by weight:

[0035]

Embodiment 3

[0037] Acrylic acid and maleic anhydride are used as monomers, and N,N'-methylenebisacrylamide is used as a crosslinking agent. The concentration of acrylic acid is 20%, the concentration of maleic anhydride is 5%, and the concentration of N,N'-methylene The base bisacrylamide concentration is 0.5%, and the polyacrylic acid-maleic anhydride water-absorbing resin 3 is prepared, wherein the cross-linked polymer accounts for 6% of the total amount of the polyacrylic acid-maleic anhydride water-absorbing resin 3.

[0038] Further make one-component polyurethane waterproof paint, comprise the component of following parts by weight:

[0039]

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com