Guide bar drives and guide bar assemblies for warp knitting machines

A technology of guide bar and driving device, which is applied in warp knitting, textiles, papermaking, knitting, etc., and can solve the problems of high mechanical cost and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

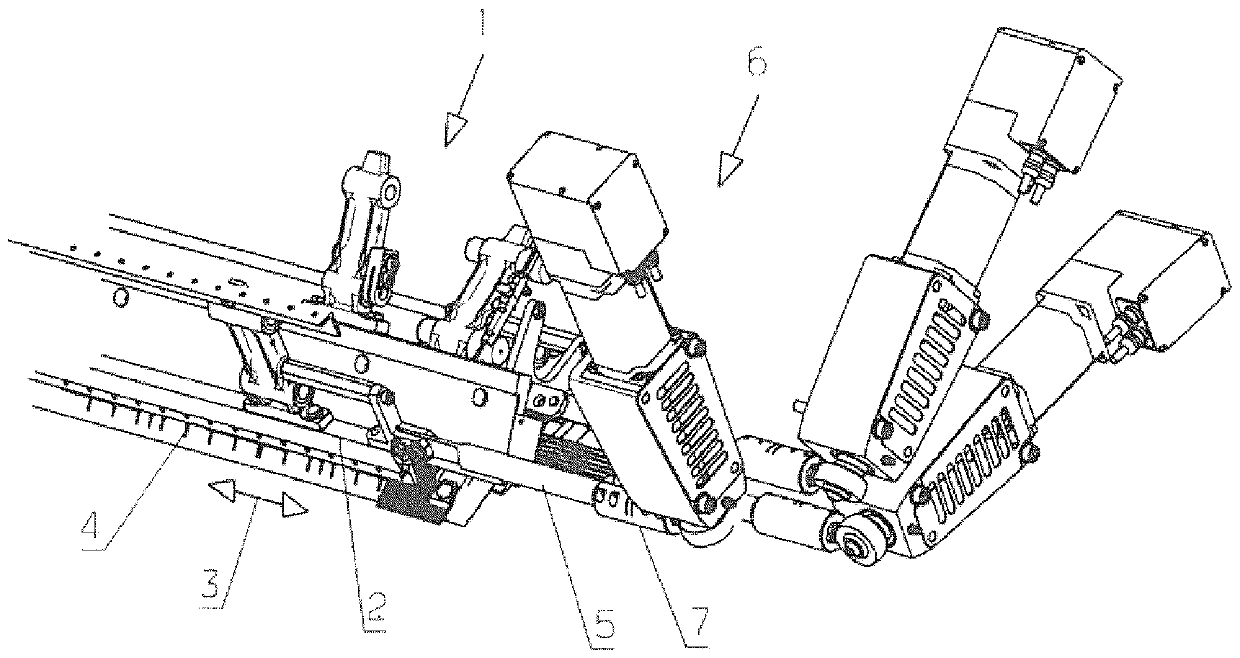

[0030] The thread guide bar assembly 1 has a plurality of thread guide bars 2 which are to be moved back and forth in the offset direction represented by the double arrow 3 . Each thread guide bar 2 carries a certain number of thread guides 4 which can be designed, for example, as thread guide needles or eyelets.

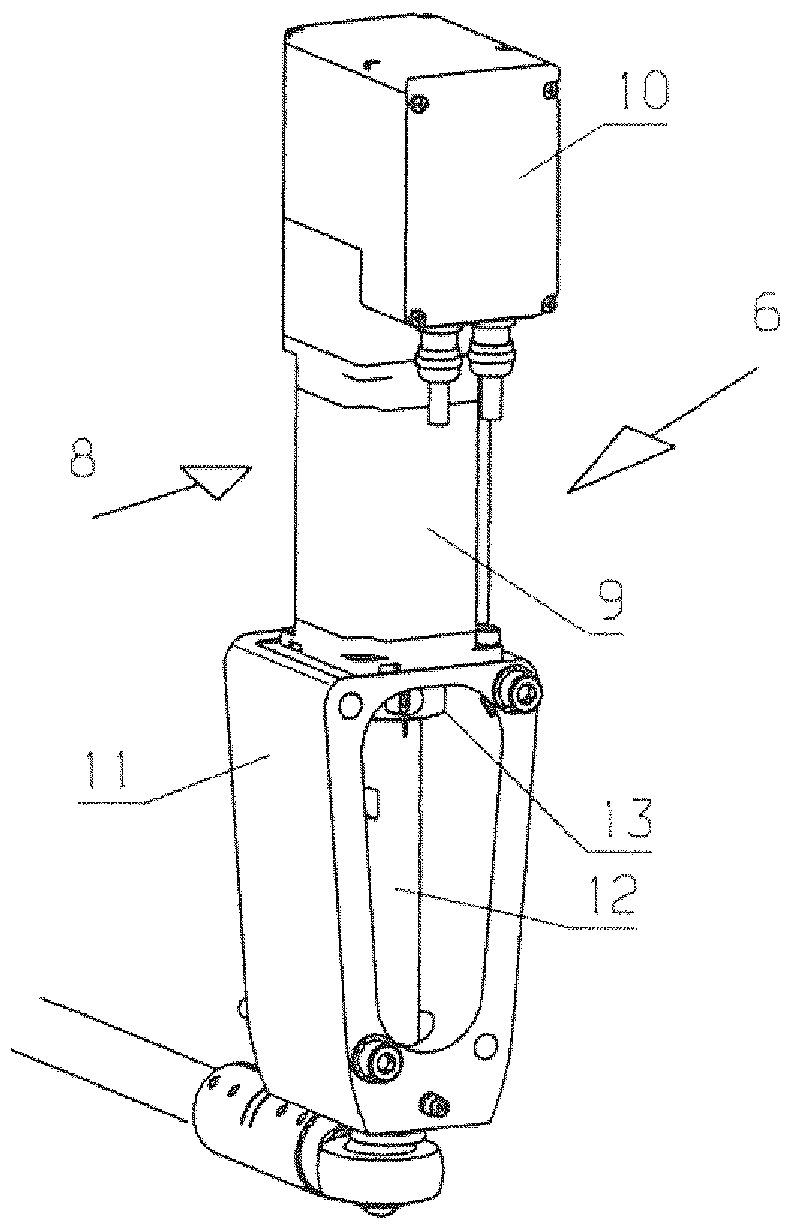

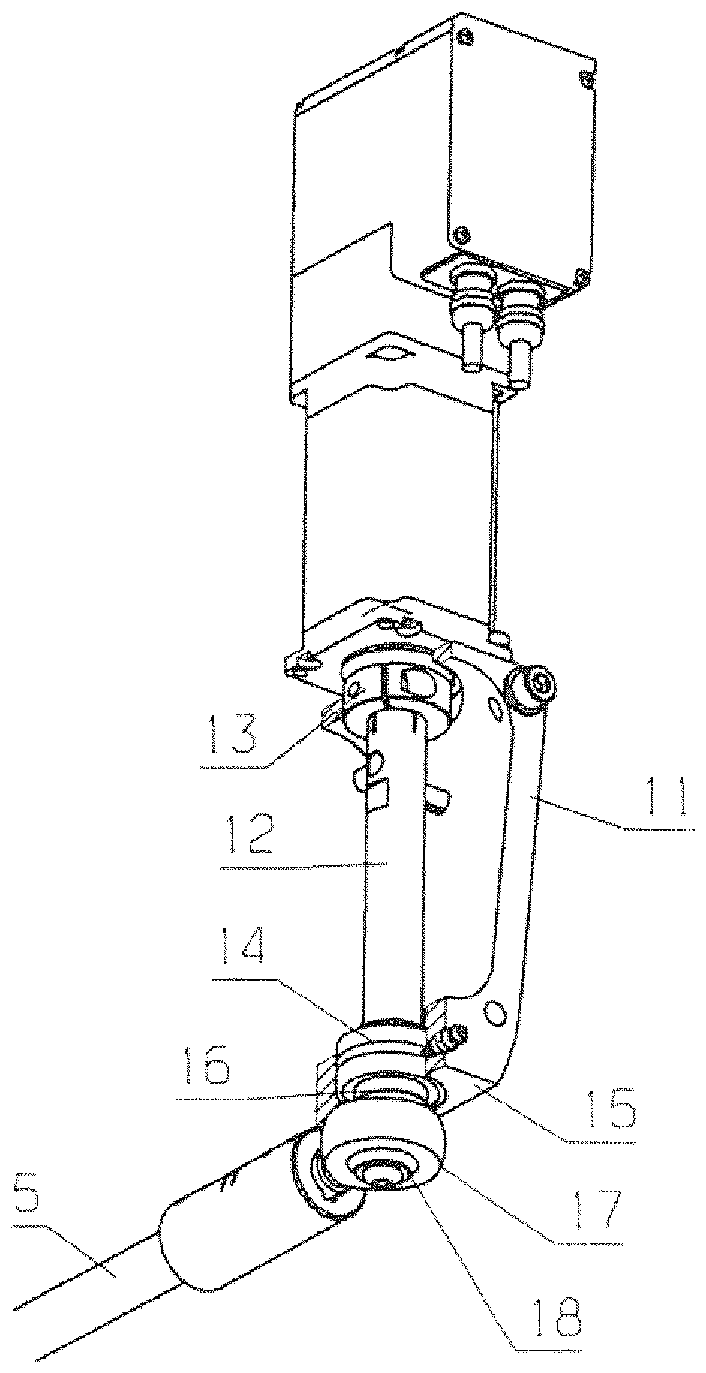

[0031] Each yarn guide bar is connected with the yarn guide bar driving device 6 via a driving push rod 5 . exist figure 1 In the embodiment of the present invention, the drive push rod 5 has a length adjustment device 7, and the length of the drive push rod 5 can be adjusted to a certain limit with the difference between the yarn guide bar 2 and the yarn guide bar drive device 6 by using the length adjustment device 7. The spacing in the neutral position of the two elements matches.

[0032] However, it is advantageous if the length adjustment device 7 is arranged in the region of the thread guide bar 2 and is preferably connected to the thread guide bar 2 . Bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com