Single-crack rock equivalent effective stress coefficient testing device and testing method

A technology of effective stress and test device, applied in the direction of measuring device, using a stable shear force to test the strength of materials, instruments, etc., can solve the problem that the effective stress coefficient is no longer applicable, and achieve simple test steps and accurate test results. Effect

Pending Publication Date: 2019-05-03

INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For fractured reservoirs, fractured fractures during oil and gas production, and hot dry roc

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

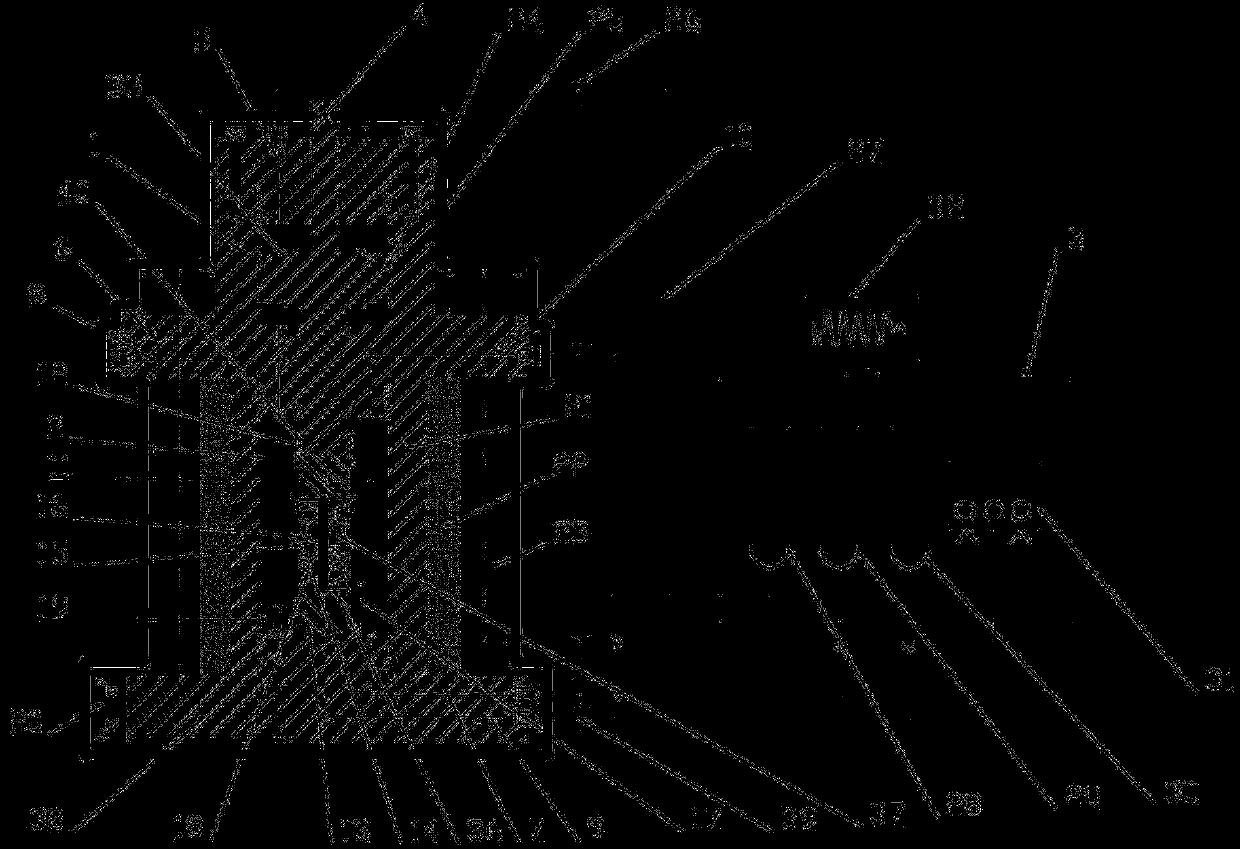

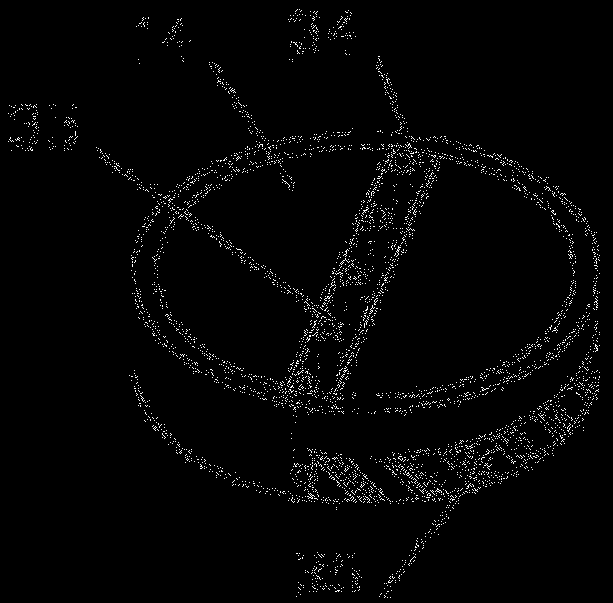

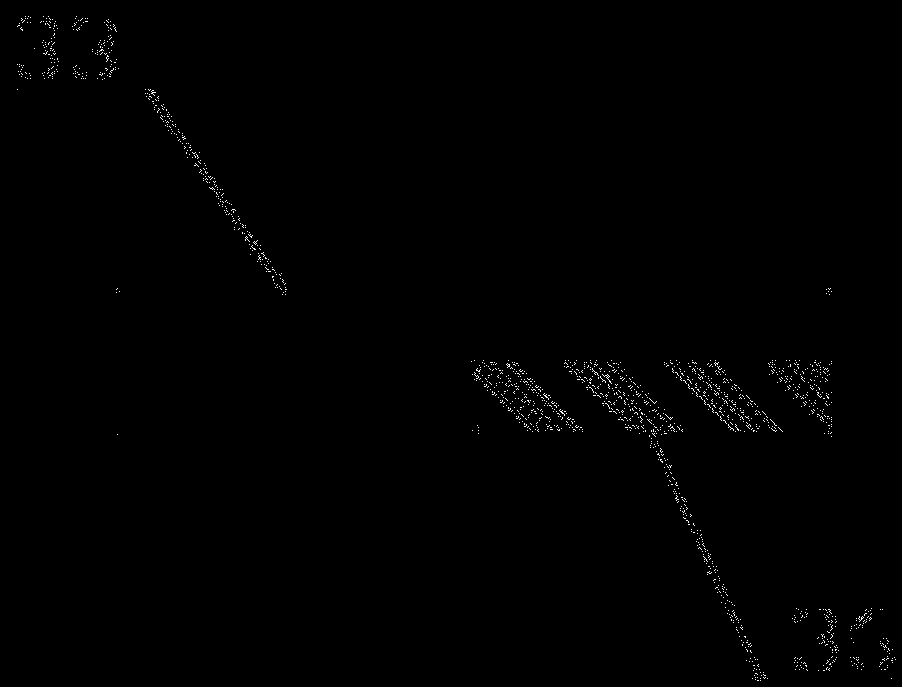

The invention relates to a single-crack rock equivalent effective stress coefficient testing device and testing method. a triaxial pressure chamber of the testing device is provided with a testing cavity; an axial loading cylinder of an axial pressure loading mechanism is arranged on the top of the triaxial pressure chamber; the internal of the axial loading cylinder communicates with an axial pressure servo pump; the telescoping end of the axial loading cylinder enters the testing cavity; a confining pressure servo pump of a confining pressure loading mechanism communicates with the testing cavity; an upper pressure head and a lower pressure head are vertically arranged in the testing cavity in an opposite manner; the upper pressure head is arranged right under the telescoping end of theaxial loading cylinder and provided with an upper fluid pressure pipeline; the lower pressure head is fixedly arranged at the bottom of the testing cavity and provided with a lower fluid pressure pipeline; the upper and lower fluid pressure pipelines communicate with a fluid pressure servo pump; and a to-be-tested rock having a single crack is placed between the upper pressure head and the lower pressure head. Thus, testing results can be more accurate.

Description

technical field [0001] The invention belongs to the technical field of rock and soil detection, and in particular relates to a single-crack rock equivalent effective stress coefficient testing device and a testing method. Background technique [0002] The single-fracture rock equivalent effective stress coefficient test method takes the shear strength as the main index, and considers the degree of weakening of the shear strength by the fluid pressure in the fracture. Based on the principle of equivalent stress, a test method for the equivalent effective stress coefficient of single-fracture rock is proposed. The concept of effective stress was first proposed by K. Terzaghi to characterize the interaction relationship between the total stress, solid skeleton stress and pore fluid pressure in the soil medium. Later, M.A. Biot revised Terzaghi's effective stress principle and introduced the Biot coefficient , the effective stress coefficient. Effective stress has important ap...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/00G01N3/24

Inventor 胡大伟丁长栋周辉邵建富张帆张传庆卢景景高阳马东东

Owner INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com