A method and system for intelligent collaborative production among multiple production lines

A production line and production end technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve problems such as reducing the work efficiency of multiple equipment or production lines, and difficulty maintaining synergy between production lines, so as to improve production efficiency and ensure high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

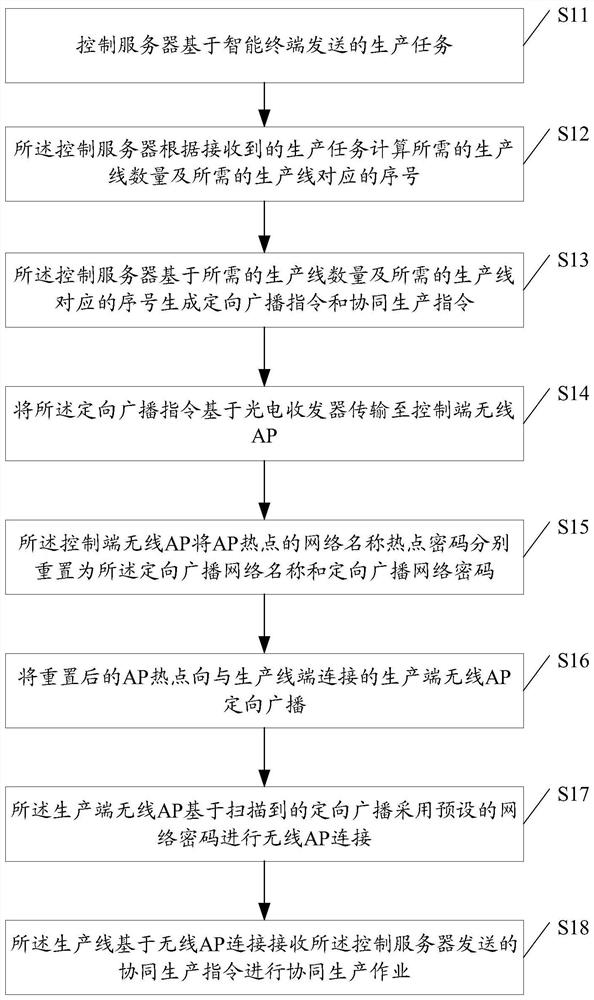

[0051] see figure 1 , figure 1 It is a schematic flowchart of a method for intelligent collaborative production among multiple production lines in an embodiment of the present invention.

[0052] Such as figure 1 As shown, a method for intelligent collaborative production between multiple production lines, the method includes:

[0053]S11: Control the production task sent by the server based on the smart terminal, the generated task is produced by the user based on the operation interface of the smart terminal, and the production task includes a production time limit and a production task amount;

[0054] In the specific implementation process of the present invention, the user generates a task through the operation interface operation on the APP preinstalled on the smart terminal or the web interface and sends it to the control server, wherein the smart terminal can be a smart terminal such as a PC computer, a tablet computer, or a smart phone equipment; among them, the us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com