Inorganic solvent purification system

A technology of inorganic solvents and purification systems, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve system manipulation difficulties, poor fluctuations of inorganic solvents, and phosphorus content of inorganic solvents and the total content of potassium content cannot reach the standard, so as to improve the speed and reduce the execution cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in connection with the drawings and embodiments.

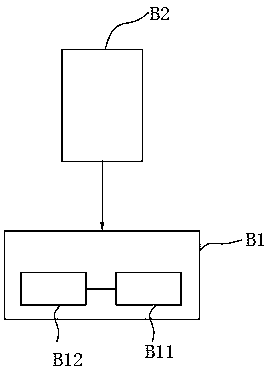

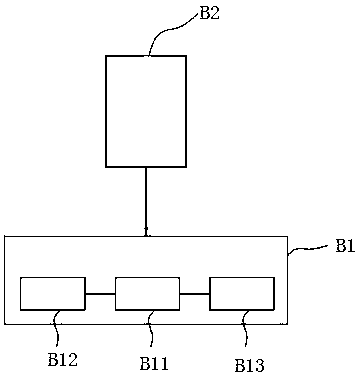

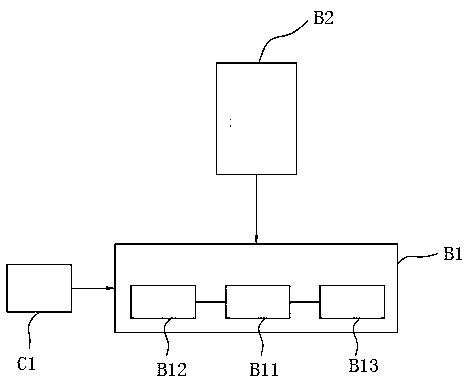

[0023] like Figure 1-Figure 4 As shown, the purification system of inorganic solvents includes the action device B1 of the solvent to be purified and the perfusion device B2. The action device of the solvent to be purified includes a cylindrical cavity B11 and a stamping device B12. The cylindrical cavity acquires and accommodates the inorganic Solvent, punching device B12 is used to supply oxygen-containing gas to cylindrical cavity B11;

[0024] The system B00 for purifying harmful solvents includes a conveying device C1, which is connected to the action device B1 of the solvent to be purified, and transfers the inorganic solvent to be acted to the cylindrical chamber B11. The action device B1 of the solvent is used to transfer the purified inorganic solvent;

[0025] The system B00 for purifying harmful solvents is attached with a conveying device C1 and a conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com