Composite extra-thick plate blank and production method thereof

A technology of extra-thick slab and production method, which is applied in the production field of composite extra-thick slab and composite extra-thick slab, can solve the problems of inability to meet the requirements of large compression ratio applications, complex equipment, long cycle, etc. Wide range, reduced requirements, improved metallographic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

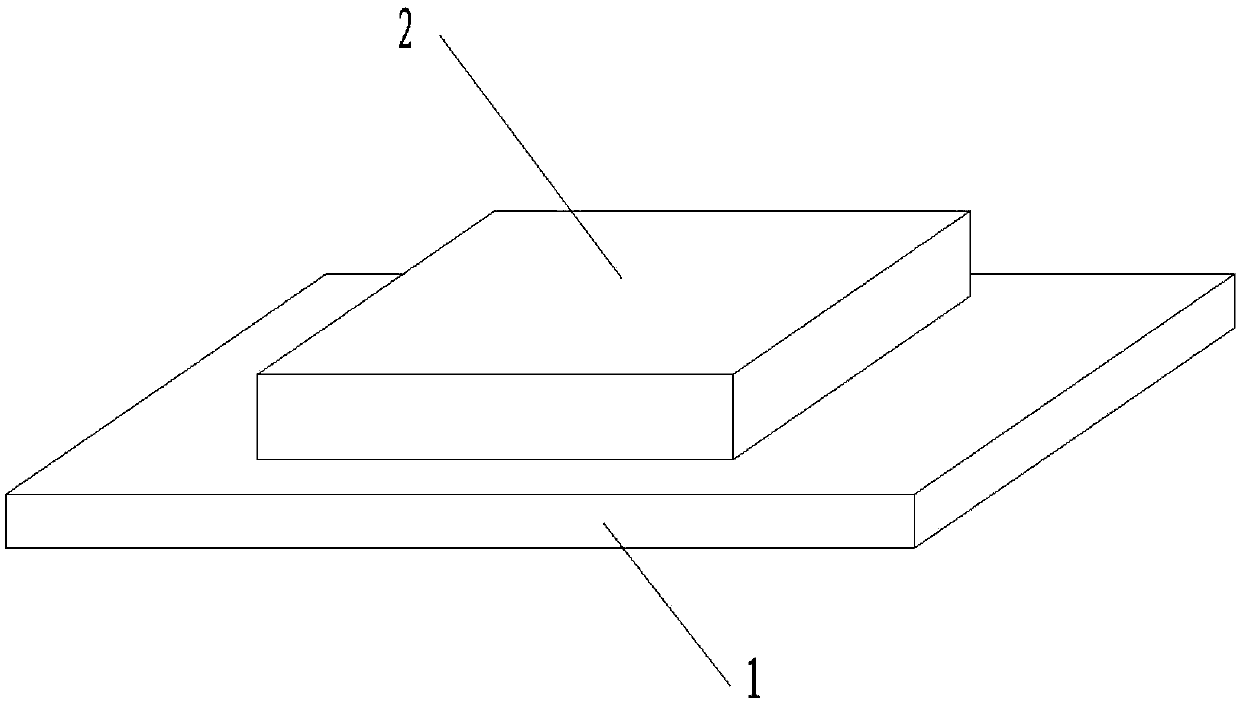

[0040] Reference attached figure 1 and figure 2 , which shows the basic structure of the composite extra-thick slab provided by the embodiment of the present invention.

[0041]A composite extra-thick slab provided in this embodiment, the composite extra-thick slab includes: a hot-rolled thick slab 1 and a heated slab 2, the hot-rolled thick slab 1 and the heated slab 2 are combined together by hot rolling, heated The thickness of the slab 2 is 2-5 times the thickness of the hot-rolled slab 1, the length of the hot-rolled slab 1 is 1.5-6 times the length of the heated slab 2, and the hot-rolled slab 1 is 10mm-100mm wider than the heated slab 2.

[0042] As a preferred embodiment, the composite extra-thick slab includes: a hot-rolled thick slab 1 and a heated slab 2, and a layer of thermite 3 or / and is coated between the hot-rolled thick slab 1 and the heated slab 2 A layer of slag remover 4, hot-rolled thick plate 1 and heated slab 2 are hot-rolled together through thermite...

Embodiment 2

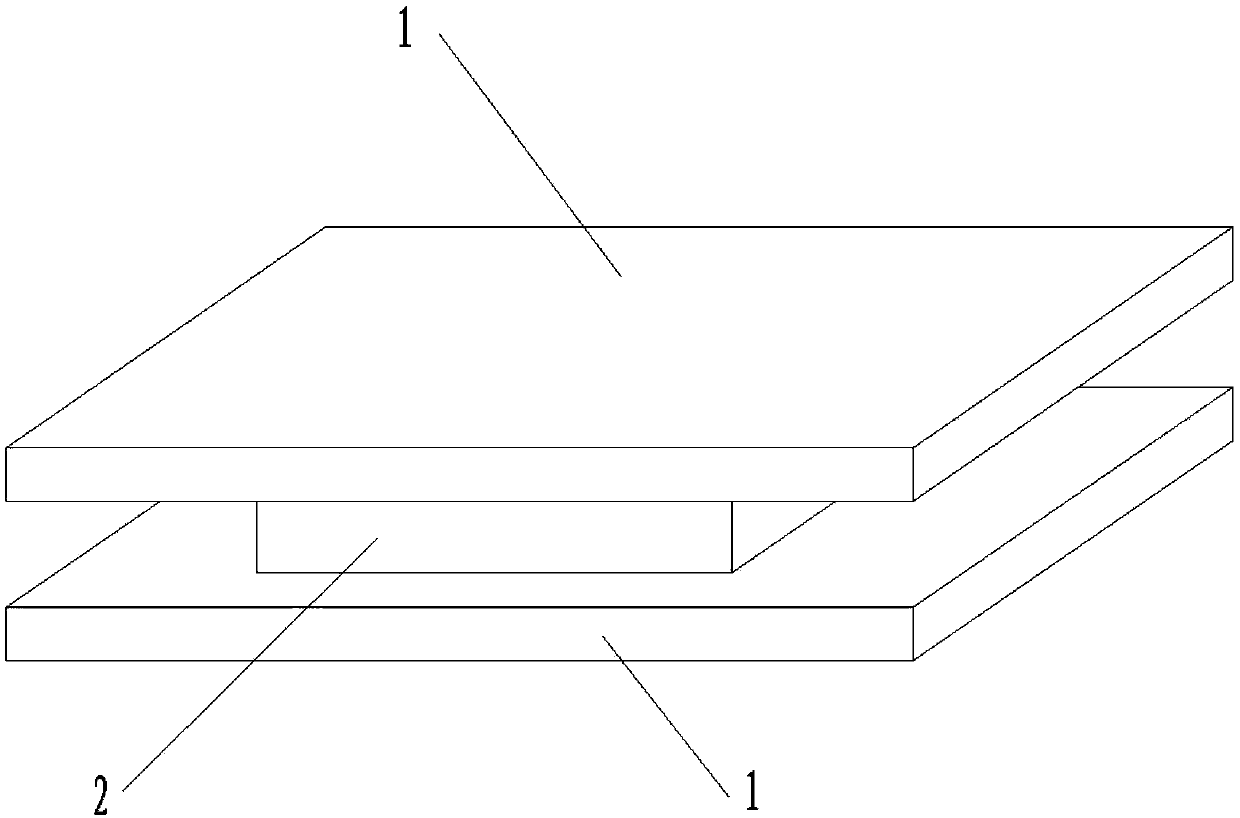

[0045] Reference attached figure 2 , which shows the basic structure of the composite extra-thick slab provided by the embodiment of the present invention.

[0046] A composite extra-thick slab provided in this embodiment, the composite extra-thick slab includes: two hot-rolled thick slabs 1 and one heated slab 2, and one heated slab 2 is arranged between the two hot-rolled thick slabs 1 Between the hot-rolled slab 1 and the heated slab 2, a layer of thermite 3 or / and a layer of slag remover 4 is coated, and one heated slab 2 and two hot-rolled slabs 1 are combined by hot rolling. Together.

[0047] Among them, two hot-rolled thick plates 1 and one heated slab 2 are composited together by hot rolling, the thickness of the heated slab 2 is 2 to 5 times the thickness of the hot-rolled thick plate 1, and the length of the hot-rolled thick plate 1 is the length of the heated slab. 1.5-6 times the length of 2, the hot-rolled thick plate 1 is 10mm-100mm wider than the heated slab...

Embodiment 3

[0049] A composite extra-thick slab provided in this embodiment, the composite extra-thick slab includes: a plurality of hot-rolled thick slabs 1 and a plurality of heated slabs 2, and the number of hot-rolled thick slabs 1 is one more than that of the heated slabs 2 A plurality of hot-rolled slabs 1 and a plurality of heated slabs 2 are alternately arranged, and a layer of thermite 3 or / and a layer of slag remover 4 is coated between adjacent heated slabs 2 and hot-rolled slabs 1 , a plurality of heated slabs 2 and a plurality of hot-rolled thick plates 1 are composited together by hot rolling.

[0050] Among them, a plurality of hot-rolled thick plates 1 and a plurality of heated slabs 2 are composited together by hot rolling, the thickness of the heated slabs 2 is 2 to 5 times the thickness of the hot-rolled thick plates 1, and the length of the hot-rolled thick plates 1 is the length of the heated plate. The length of the billet 2 is 1.5 to 6 times, and the hot-rolled thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com